A kind of preparation method of silane modified concrete internal curing agent

An internal and silane modification technology for concrete, applied in the field of concrete admixtures, can solve the problems of high water absorption rate, fast water absorption rate, and reduced concrete work performance, etc. The contradictory effects of sex and self-contraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

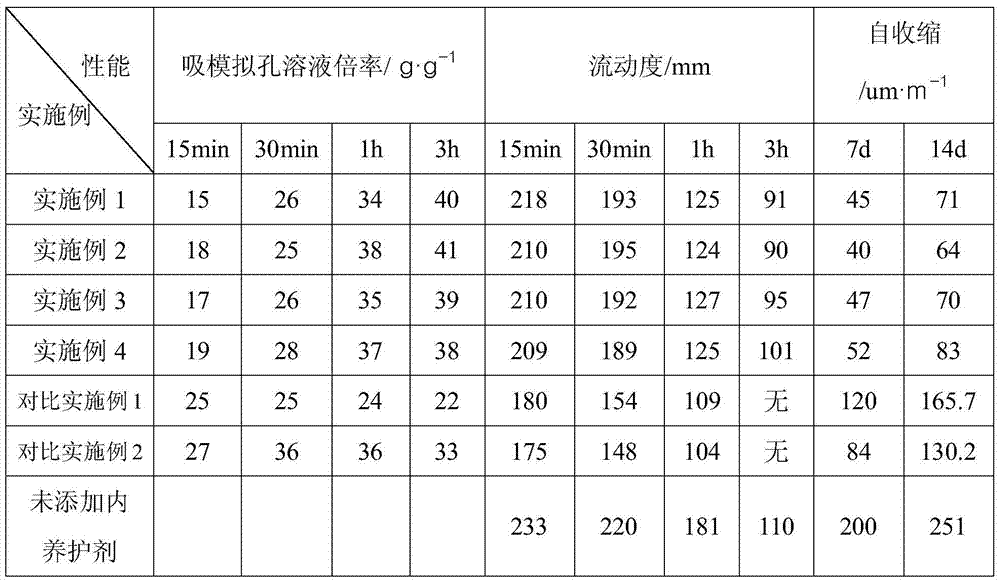

Examples

Embodiment 1

[0025] A preparation method of silane-modified concrete internal curing agent, comprising the following steps:

[0026] Add 53.3g of 30% sodium hydroxide solution into 36g of acrylic acid to prepare an 80% acrylic acid solution with a neutralization degree;

[0027] Dissolve 3.6g of polyvinyl alcohol 1788 completely in 87.1g of water, then add the above-mentioned neutralized acrylic acid solution, 0.18g of N,N'-methylenebisacrylamide and 1.08g of ammonium persulfate and mix well, after heating to 40°C React for 12 hours to obtain a superabsorbent resin gel, and obtain a 150-200 mesh superabsorbent resin after granulation, drying, crushing, sieving and surface crosslinking;

[0028] Disperse 25g of 3,4 epoxycyclohexylethyltrimethoxysilane in 75g of benzene, then add 50g of superabsorbent resin and mix thoroughly, put it in an oven at 120°C for 2 hours to obtain the final concrete internal curing agent.

Embodiment 2

[0030] A preparation method of silane-modified concrete internal curing agent, comprising the following steps:

[0031] Add 53.3g of 30% sodium hydroxide solution into 36g of acrylic acid to prepare an 80% acrylic acid solution with a neutralization degree;

[0032] Completely dissolve 10.8g of polyvinyl alcohol 1788 in 79.9g of water, then add the above-mentioned neutralized acrylic acid solution, 0.72g of N,N'-methylenebisacrylamide and 2.16g of potassium persulfate and mix well, after heating to 60°C React for 8 hours to obtain a superabsorbent resin gel, and obtain a 150-200 mesh superabsorbent resin after granulation, drying, crushing, sieving and surface crosslinking;

[0033] Disperse 40g of glycidyl etheroxypropyltrimethoxysilane in 120g of benzene, then add 50g of superabsorbent resin and mix thoroughly, put it in an oven at 160°C for 1 hour, and obtain the final concrete internal curing agent.

Embodiment 3

[0035] A preparation method of silane-modified concrete internal curing agent, comprising the following steps:

[0036] Add 53.3g of 30% sodium hydroxide solution into 36g of acrylic acid to prepare an 80% acrylic acid solution with a neutralization degree;

[0037] Completely dissolve 7.2g of polyvinyl alcohol 1788 in 23.5g of water, then add the above-mentioned neutralized acrylic acid solution, 0.45g of N,N'-methylenebisacrylamide and 1.62g of sodium persulfate and mix well, after heating to 50°C React for 10 hours to obtain a superabsorbent resin gel, and obtain a 150-200 mesh superabsorbent resin after granulation, drying, crushing, sieving and surface crosslinking;

[0038] Disperse 40g of glycidyl etheroxypropyltrimethoxysilane in 120g of benzene, then add 50g of superabsorbent resin and mix thoroughly, put it in an oven at 160°C for 1 hour, and obtain the final concrete internal curing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com