New-type nutritional-type powder anti-blocking agent and application

A nutritional and anti-caking agent technology, applied in the field of fertilizer manufacturing, to achieve the effects of avoiding uneven application, improving fertilizer utilization rate, and uniform absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A new nutritional powder anti-caking agent, each material is calculated by mass percentage, is characterized in that: it is mixed with talc, sulfur powder, zinc oxide, alginic acid, brassinolide, nitrification inhibitor and nitrogen-fixing bacteria Vegetable oil leftovers and oxo fatty alcohol distillation residue are compounded at a ratio of 3:2 to modify the surface with surfactants, including 40% talc, 30% sulfur powder, 10% zinc oxide, and 5% alginic acid , 5% brassinolide, 5% nitrification inhibitor, 5% nitrogen-fixing bacteria, and the powders were all pulverized into a particle size of 500 mesh (American Standard D95).

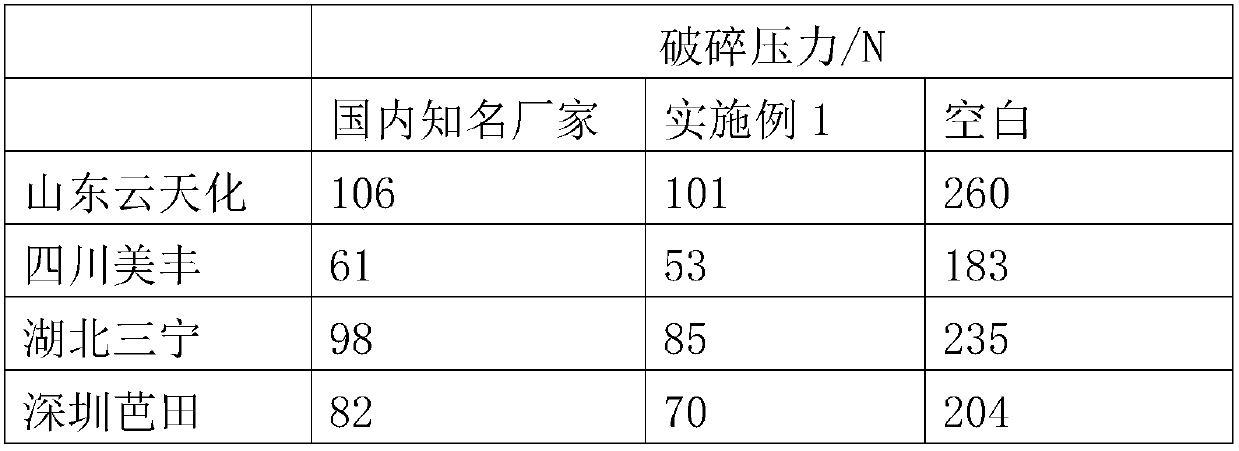

[0016] The following is verified by testing the coating rate of the powder-coated fertilizer and the fertilizer crushing pressure experiment:

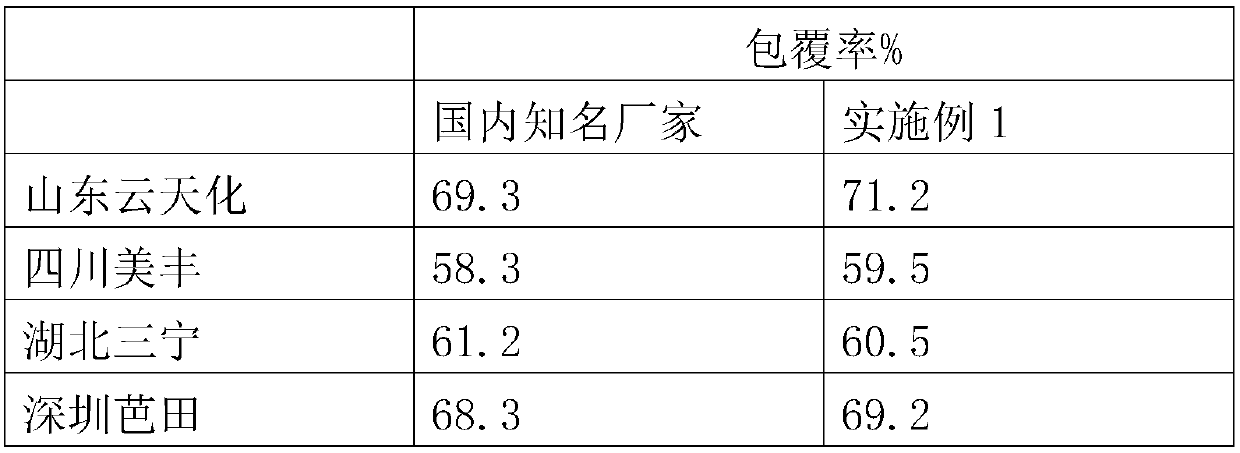

[0017] Experiment 1------The coating rate of new nutritional powder anti-caking agent on fertilizer

[0018] 1. Sampling

[0019] A well-known domestic manufacturer and the samples in Example 1 respecti...

Embodiment 2

[0040] A new nutritional powder anti-caking agent, each material is calculated by mass percentage, is characterized in that: it is mixed with talc, sulfur powder, zinc oxide, alginic acid, brassinolide, nitrification inhibitor and nitrogen-fixing bacteria Vegetable oil leftovers and oxo fatty alcohol distillation residue are compounded at a ratio of 3:2 to modify the surface with surfactants, including 20% talc, 35% sulfur powder, 10% zinc oxide, and 5% boron oxide , 29.7% of alginic acid, 0.1% of gibberellin, 0.1% of urease inhibitor, 0.1% of Bacillus subtilis, and the powders are all pulverized into a particle size of 1000 mesh (American Standard D95).

[0041] The following is verified by testing the coating rate of the powder-coated fertilizer and the fertilizer crushing pressure experiment:

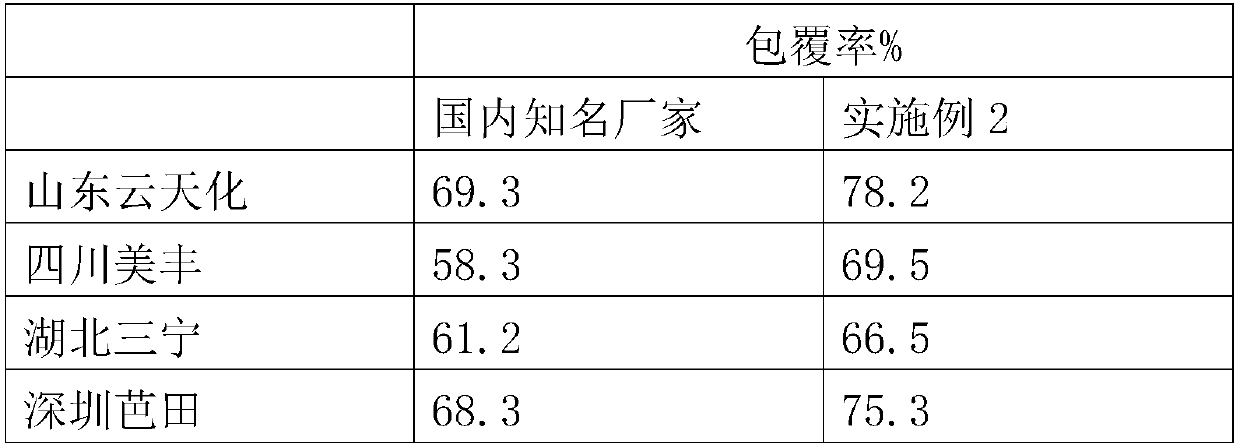

[0042] Experiment 1------The coating rate of new nutritional powder anti-caking agent on fertilizer

[0043] 1. Sampling

[0044] A well-known domestic manufacturer and the sampl...

Embodiment 3

[0065] A new type of nutritional powder anti-caking agent, each material is calculated by mass percentage, characterized in that: it is mixed with talc, sulfur powder, fulvic acid, cytokinin, nutrient activator and silicate bacteria, mixed with vegetable oil Leftovers and oxo fatty alcohol distillation residue are compounded at a ratio of 3:2 to modify the surface with surfactants, including 90% talc, 0.1% sulfur powder, 0.1% fulvic acid, and 3% cytokinin , 5.8% nutrient activator, 1% silicate bacteria, and the powder is ground into a particle size of 200 mesh (American Standard D95).

[0066] The following is verified by testing the coating rate of the powder-coated fertilizer and the fertilizer crushing pressure experiment:

[0067] Experiment 1------The coating rate of new nutritional powder anti-caking agent on fertilizer

[0068] 1. Sampling

[0069] A well-known domestic manufacturer and samples in Example 3 were used for Shandong Yuntianhua nitro high tower granulatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com