Preparation process of cefuroxime sodium for injection

A cefuroxime sodium and preparation process technology, which is applied in the field of preparation process of cefuroxime sodium for injection, can solve problems such as improper operation, influence on drug quality and safety, easy residual solvent, etc., to promote precipitation and improve crystallization effect , the effect of reducing residual water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

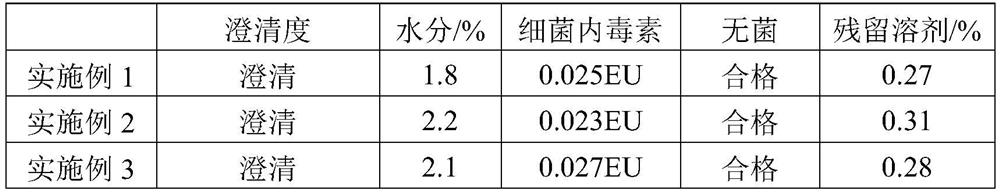

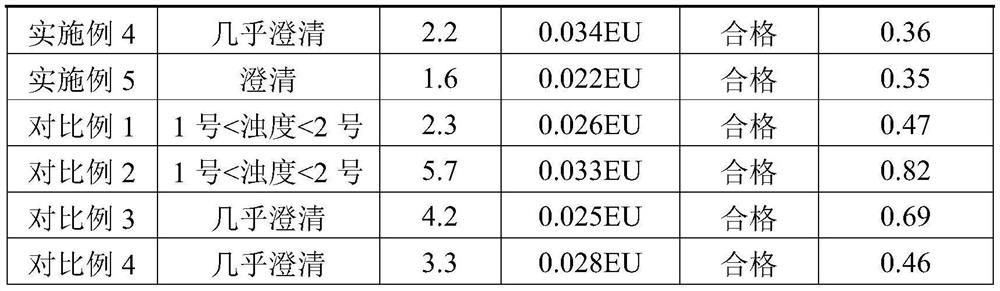

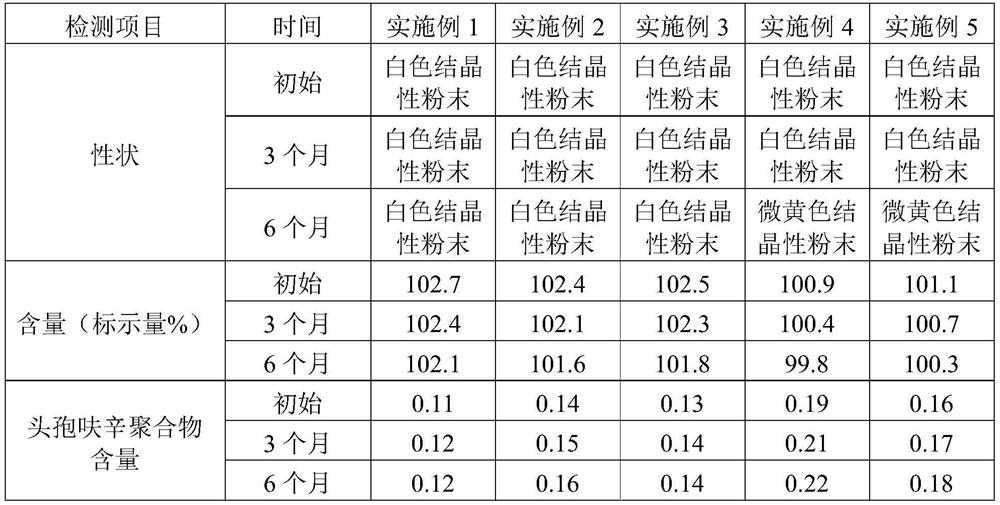

Examples

Embodiment 1

[0026] A preparation process of cefuroxime sodium for injection, comprising the following steps:

[0027] S1. Prepare phosphate buffered saline solution: mix disodium hydrogen phosphate solution and sodium dihydrogen phosphate solution, adjust the pH to 6.8, perform aseptic treatment, and prepare a phosphate buffer solution with a concentration of 0.2mol / L;

[0028] S2. Preparation of resin: crush starch to 350 mesh, dissolve starch with water, then add poly-N-isopropylacrylamide 1.5 times the weight of starch and 0.75 times N,N-methylenebisacrylamide, Control the temperature at 190°C and control the pressure at 0.55 MPa. After treatment for 40 minutes, return to the normal pressure level, filter, take the filter cake to granulate, soak the granules in the phosphate buffer solution of step S1 for 20 minutes, and dry to obtain the resin ;

[0029] S3. Decolorization: Add cefuroxime sodium to the phosphate buffered saline solution in step S1, stir until completely dissolved, ad...

Embodiment 2

[0032] A preparation process of cefuroxime sodium for injection, comprising the following steps:

[0033] S1. Prepare phosphate buffered saline solution: mix disodium hydrogen phosphate solution and sodium dihydrogen phosphate solution, adjust the pH to 7.0, perform aseptic treatment, and prepare a phosphate buffer solution with a concentration of 0.2mol / L;

[0034] S2. Preparation of resin: crush the starch to 200 mesh, dissolve the starch with water, then add poly-N-isopropylacrylamide 1.6 times the weight of the starch and 0.83 times the N, N-methylene bisacrylamide. Control the temperature at 195°C and control the pressure at 0.5 MPa. After treatment for 1 hour, return to the normal pressure level, filter, take the filter cake to granulate, soak the granules in phosphate buffer solution for 10 minutes, and dry to obtain the resin;

[0035] S3. Decolorization: Add cefuroxime sodium to the phosphate buffered saline solution in step S1, stir until completely dissolved, add ac...

Embodiment 3

[0038] A preparation process of cefuroxime sodium for injection, comprising the following steps:

[0039] S1. Prepare phosphate buffered saline solution: mix disodium hydrogen phosphate solution and sodium dihydrogen phosphate solution, adjust the pH to 6.5, perform aseptic treatment, and prepare a phosphate buffer solution with a concentration of 0.2mol / L;

[0040] S2. Preparation of resin: crush the starch to 400 mesh, dissolve the starch with water, then add 1.5 times the weight of starch poly-N-isopropylacrylamide and 0.7 times the weight of N,N-methylenebisacrylamide, Control the temperature at 185°C and control the pressure at 0.65MPa. After 0.5h of treatment, return to the normal pressure level, filter, take the filter cake to granulate, soak the granules in phosphate buffer solution for 30min, and dry to obtain the resin;

[0041] S3. Decolorization: Add cefuroxime sodium to the phosphate buffered saline solution in step S1, stir until completely dissolved, add activat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com