Method for improving softness of bamboo pulp fiber through laccase-assisted cellulase treatment

A technology of cellulase and bamboo pulp fiber, which is applied in the field of pulp and paper making, can solve the problems of low reaction efficiency, few adsorption sites of cellulase, and high lignin content, so as to improve softness, reduce environmental pollution, and increase exposure area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

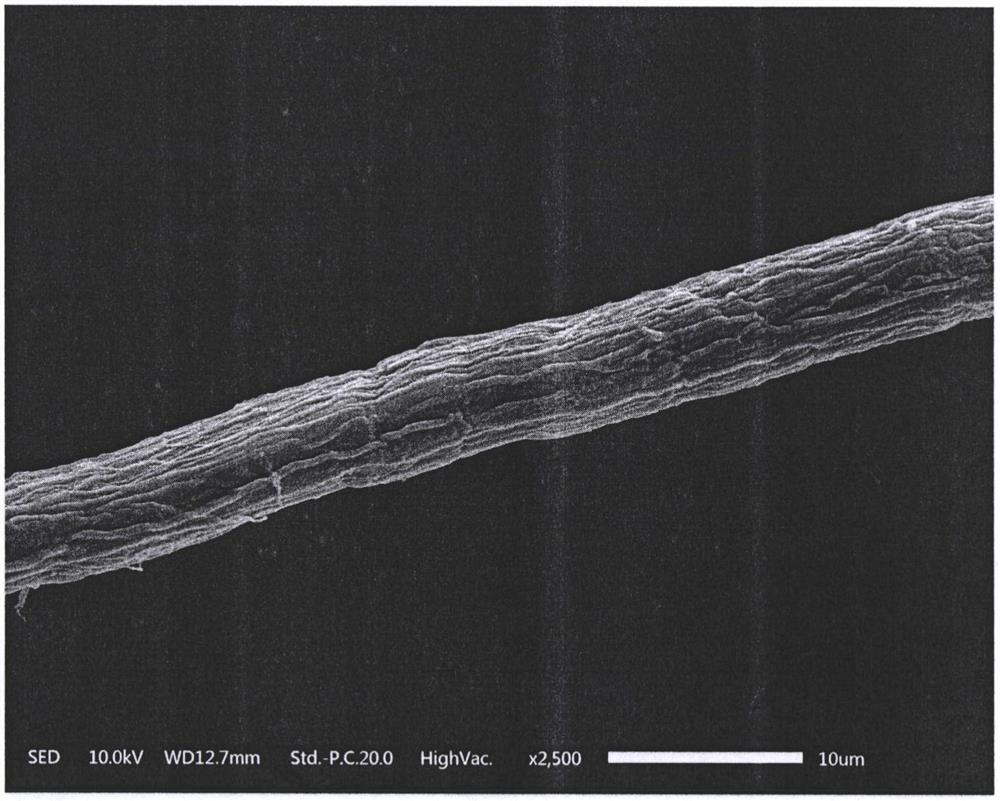

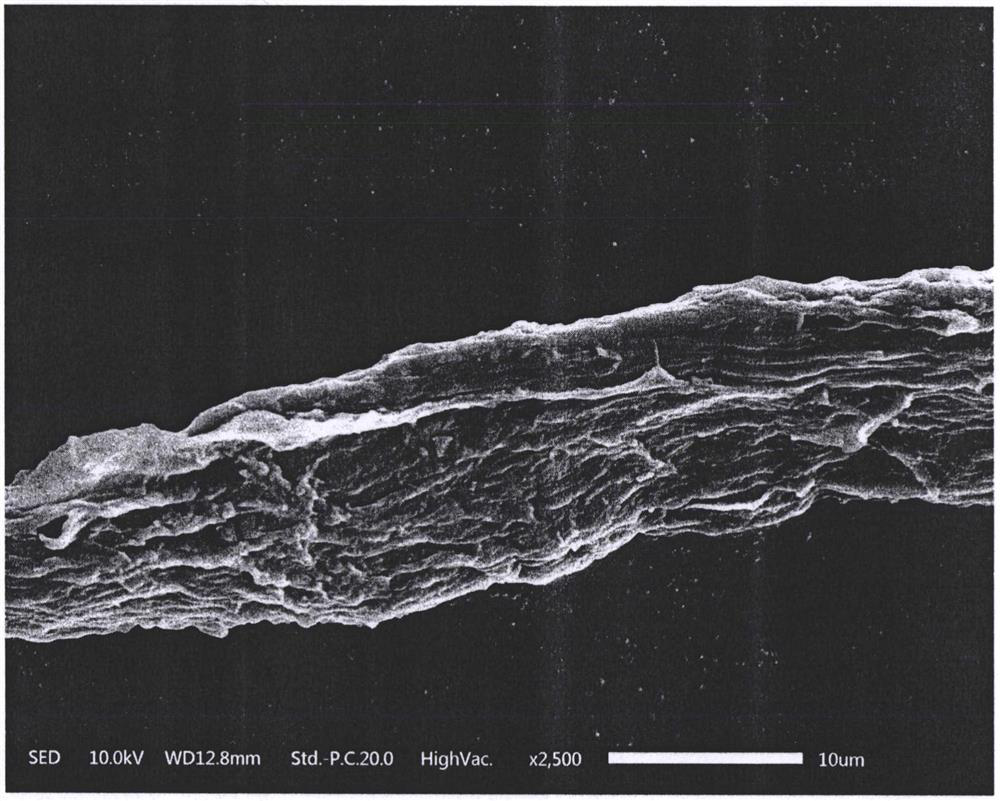

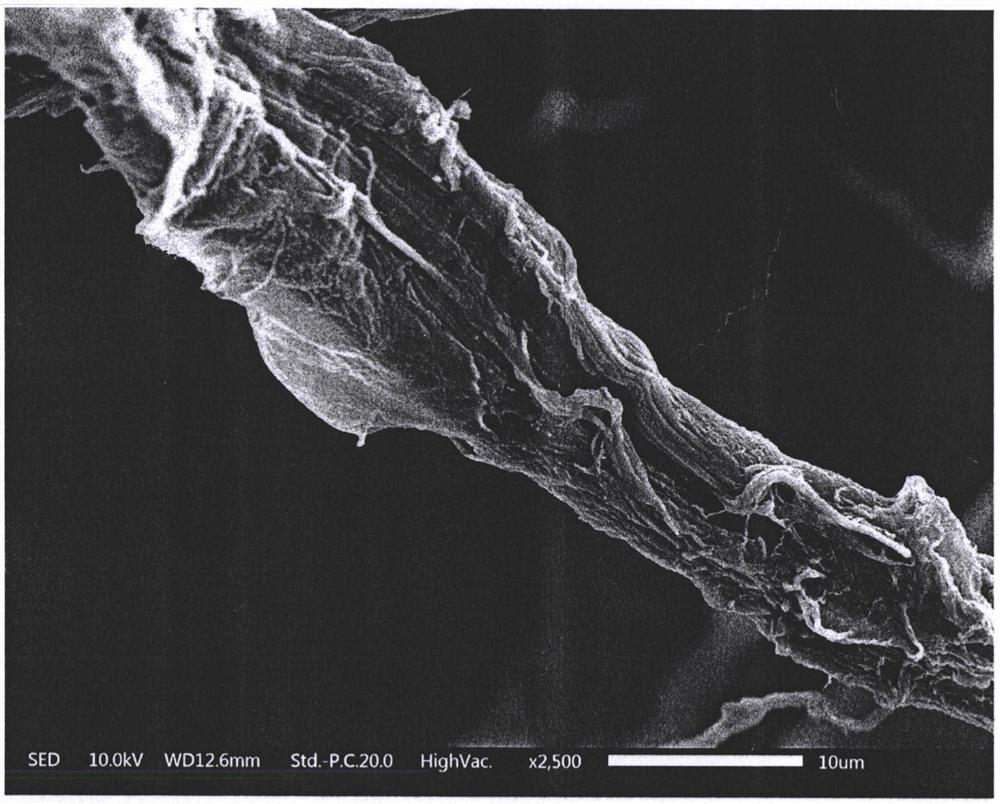

Image

Examples

Embodiment 1

[0018] A kind of method utilizing laccase treatment to improve the softness of bamboo pulp fiber, comprises the steps:

[0019] Step 1: decompress the high-yield bamboo pulp until the fibers are completely dispersed; obtain fiber pulp;

[0020] Step 2: Take five fiber slurries with equal absolute dry mass, adjust the pH value to 6.5 and add water to adjust the mass concentration of the fiber slurries to 2%, put these five slurries into laccase and mediator lacquer respectively The enzyme dosage is 10U / g, 20U / g, 30U / g, 50U / g, 60U / g respectively, the mediator dosage is 1.5%, and a water bath is used to maintain the temperature when the laccase acts.

[0021] Step 3: Squeeze out the moisture from the material obtained in step 2, and measure the softness of a single fiber by measuring the bending degree of the fiber with the glass-wire method to quantitatively analyze the softness of the fiber. See Tables 1 and 2.

[0022] Table 1 Effect of laccase treatment time on the softness...

Embodiment 2

[0027] The method for improving the softness of bamboo pulp fibers in combination with laccase action and cellulase treatment comprises the steps:

[0028] Step 1: decompress the high-yield bamboo pulp until the fibers are completely dispersed to obtain fiber pulp;

[0029] Step 2: Take six equal-quality fiber slurries, adjust the pH value to 6.5 and add water to adjust the mass concentration of the fiber slurries to 2%, and put these five parts of slurries into laccase and mediator respectively. 0U / g, 10U / g, 20U / g, 30U / g, 40U / g, 50U / g, the amount of mediator is 1.5%, and a water bath is used to maintain the temperature when the laccase acts.

[0030] Step 3: Adjust the pH value of the material obtained in Step 2 to 6.5 and adjust the mass concentration of the fiber slurry to 1%. After heating up to 50°C, add cellulase so that the dosage of cellulase is 0EGU / g and 0.2EGU respectively / g, 0.6EGU / g, 0.9EGU / g, 2EGU / g, 3EGU / g, act for 50min.

[0031] Step 4: Squeeze out the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com