Insole paper board for shoe

A technology for cardboard and shoes, used in papermaking, fiberboard, textiles and papermaking, etc., can solve the problems of low water recycling rate, environmental pollution, high resource cost, increase the degree of splitting, ensure flexural strength and resistance to resistance. Tension strength, the effect of solving resource recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

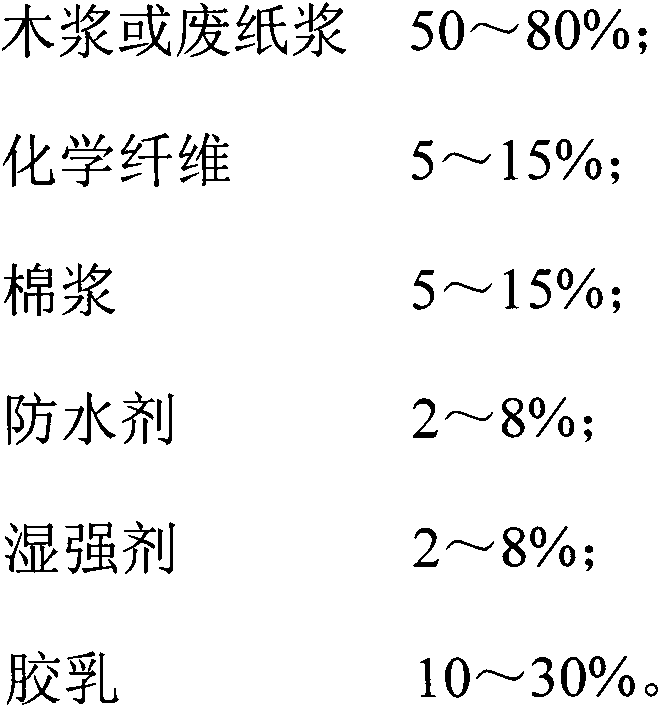

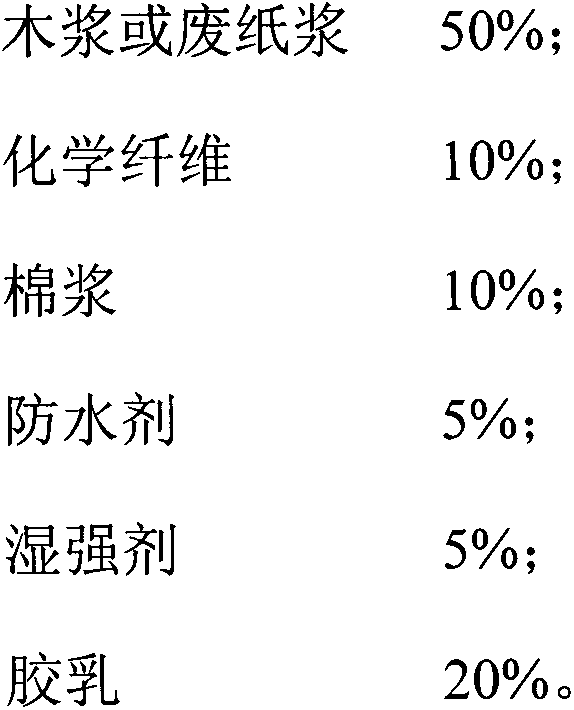

[0015] A kind of insole cardboard for shoes is prepared from the following raw materials in weight percentage:

[0016] Wood pulp or waste paper pulp 50%; chemical fiber 10%; cotton pulp 10%; waterproofing agent 5%; wet strength agent (PAE or melamine formaldehyde resin) 5%; latex: 20%.

[0017] Put the above raw materials into the rotary screen machine to produce according to the conventional production method of this profession. The prepared cardboard is inspected according to the industry standard "Shoemaking Cardboard" GB / T22803-2008, which can reach the quality standard of high-grade products. The specific testing standards are as follows:

[0018] 1. Quantitative: (150~1800) grams / square meter

[0019] 2. Thickness: (0.3~3.0)±10% mm

[0020] 3. Tightness: 0.7±0.2 g / cubic centimeter

[0021] 4. High temperature drying 1h shrinkage %: ≤0.8%

[0022] 5. Interlayer peel strength kN m -1 : ≥0.4

[0023] 6. Flex index: ≥2.9

[0024] 7. Tensile strength after soaking in ...

Embodiment 2

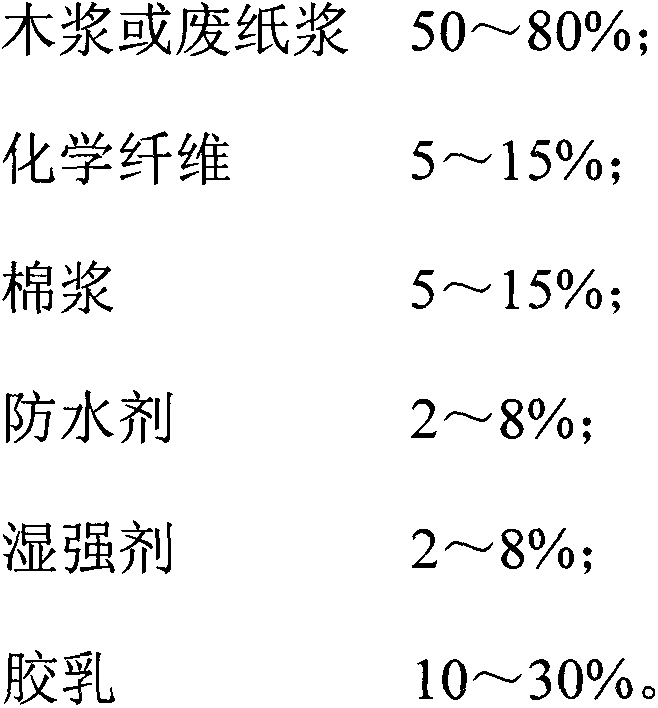

[0027] A kind of insole cardboard for shoes is prepared from the following raw materials in weight percentage:

[0028] Wood pulp or waste paper pulp 50%; chemical fiber 10%; cotton pulp 15%; waterproofing agent 5%; wet strength agent 5%; latex: 15%. Add the above-mentioned raw materials into the fourdrinier paper machine to produce according to the conventional production method of this profession. The prepared cardboard is inspected according to the industry standard "Shoemaking Cardboard" GB / T22803-2008 and can reach the quality standard of superior products.

Embodiment 3

[0030] A kind of insole cardboard for shoes is prepared from the following raw materials in weight percentage:

[0031] Wood pulp or waste paper pulp 60%; chemical fiber 5%; cotton pulp 5%; waterproofing agent 5%; wet strength agent 5%; latex: 20%.

[0032] Put the above raw materials into the rotary screen machine to produce according to the conventional production method of this profession. The prepared cardboard is inspected according to the industry standard "Shoemaking Cardboard" GB / T22803-2008 and can reach the quality standard of superior products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com