Wood chip pretreatment method and pulping method for grey paperboard production

A grey board and pretreatment technology, applied in pulp beating/refining method, pretreatment with alkaline compounds, raw material pretreatment, etc., can solve the problems of high energy consumption for refining and poor pulp quality, and improve pulp quality. , easy to operate, improve the effect of beating degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

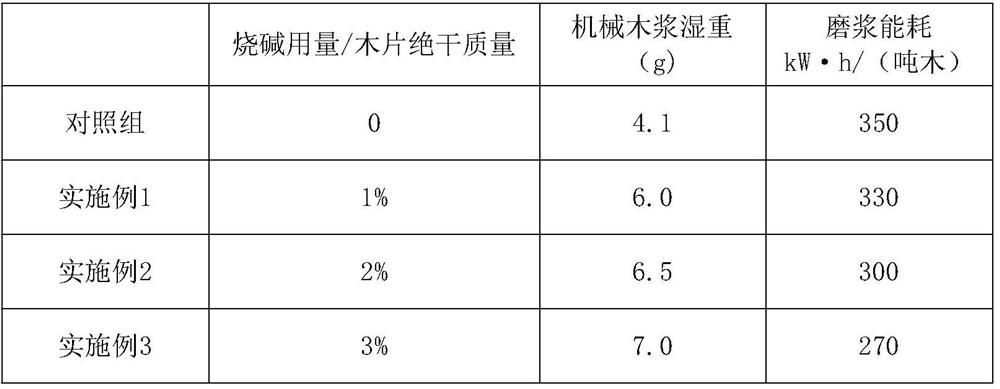

Embodiment 1

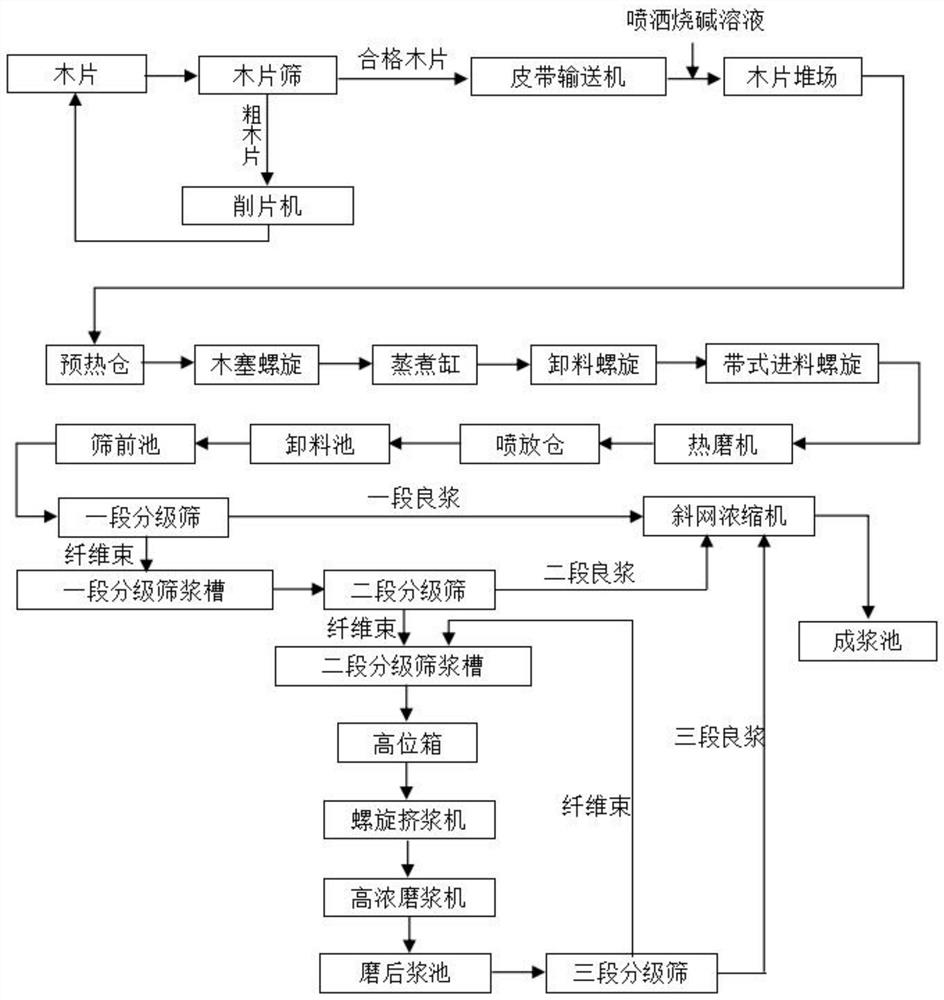

[0027] Embodiment 1: a kind of wood chip pretreatment method for gray cardboard production comprises the following steps:

[0028] (1) Chipping, cutting wood chips by a chipper, controlling the length of the wood chips to be 45mm, the width to be 30mm, and the thickness to be 5mm;

[0029] (2) Screen wood chips, use a wood chip sieve to screen the wood chips, and remove the coarse wood chips and debris on the surface of the wood chips to obtain qualified wood chips, which are transported to the wood chip yard by a belt conveyor;

[0030] (3) Spray caustic soda solution. During the process of conveying qualified wood chips by the belt conveyor, use a spray device to evenly spray caustic soda solution on the wood chips to fully wet the wood chips. It will weaken the bonding force between fibers, reduce the softening temperature of hemicellulose and lignin, and make the softening effect of wood chips better;

[0031] (4) Storage: After spraying the caustic soda solution, the woo...

Embodiment 2

[0041] Embodiment 2: a kind of wood chip pretreatment method for gray cardboard production, comprises the following steps:

[0042] (1) Chipping, cutting wood chips by a chipper, controlling the length of the wood chips to be 45mm, the width to be 30mm, and the thickness to be 5mm;

[0043] (2) Screen wood chips, use a wood chip sieve to screen the wood chips, and remove the coarse wood chips and debris on the surface of the wood chips to obtain qualified wood chips, which are transported to the wood chip yard by a belt conveyor;

[0044] (3) Spray caustic soda solution. During the process of conveying qualified wood chips by the belt conveyor, use a spray device to evenly spray caustic soda solution on the wood chips to fully wet the wood chips. It will weaken the bonding force between fibers, reduce the softening temperature of hemicellulose and lignin, and make the softening effect of wood chips better;

[0045] (4) Storage: After spraying the caustic soda solution, the wo...

Embodiment 3

[0055] Embodiment 3: a kind of wood chip pretreatment method for gray cardboard production, comprises the following steps:

[0056] (1) Chipping, cutting wood chips by a chipper, controlling the length of the wood chips to be 45mm, the width to be 30mm, and the thickness to be 5mm;

[0057] (2) Screen wood chips, use a wood chip sieve to screen the wood chips, and remove the coarse wood chips and debris on the surface of the wood chips to obtain qualified wood chips, which are transported to the wood chip yard by a belt conveyor;

[0058] (3) Spray caustic soda solution. During the process of conveying qualified wood chips by the belt conveyor, use a spray device to evenly spray caustic soda solution on the wood chips to fully wet the wood chips. It will weaken the bonding force between fibers, reduce the softening temperature of hemicellulose and lignin, and make the softening effect of wood chips better;

[0059] (4) Storage: After spraying the caustic soda solution, the wo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com