A kind of high-strength water-resistant environment-friendly kraft cardboard and its preparation method

A kraft cardboard, high-strength technology, applied in the field of papermaking, can solve problems such as breakage, easy separation of kraft cardboard, and difficulty in printing on the surface of kraft cardboard, and achieve the effect of increased strength, high repeatability, and fast drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

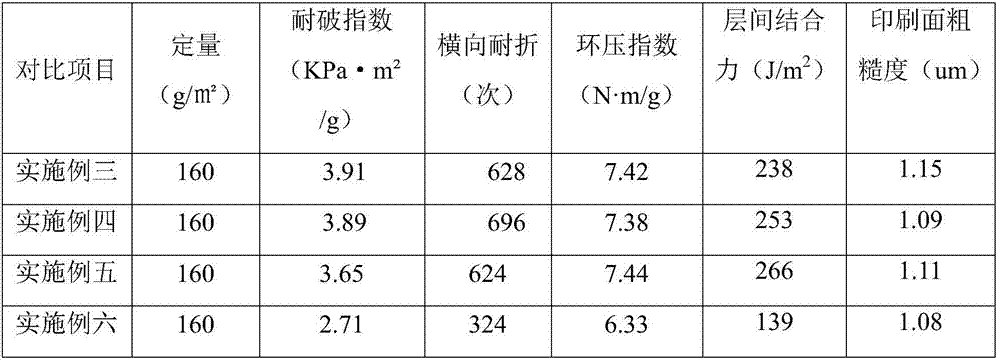

[0045] The recovered office waste paper is pulped, sand removed, fiber sieved and refined to obtain waste paper pulp. The pulp concentration is 3.0%, and then divided into four parts, adding 20% calcium carbonate and 20% unmodified silicon Limestone, 20% modified wollastonite and 40% modified wollastonite, then papermaking, drying, and paper-making, and then the physical properties of the obtained paper were measured, and the main physical and chemical indicators of wollastonite: particle size 1000 mesh , aspect ratio 10-15, fiber length 0.1-0.2mm, pH 7-8, modified by cationic polyacrylamide to obtain modified wollastonite whose isoelectric point is around pH 6, the results are as follows:

[0046] Test classification Quantitative / (g / m 2 )

[0047] It can be seen from the table that the addition of modified wollastonite has improved the physical references of the waste paper pulp to a certain extent. After mixing with domestic waste paper pulp for papermaking, th...

Embodiment 2

[0049] Put the prepared coniferous wood and broad-leaved wood into the 3.7M continuous hydraulic pulper for pulverization, dissociate the raw materials, and control the concentration of wood pulp fiber raw materials to 4.0-5.0%, and then the needles The initial pulp of leaf wood pulp and hardwood pulp is added to the conical mill for beating, and the beating is further diluted. The concentration of the resulting refined pulp is 2-3.2%, and the beating degree of softwood pulp is 20-25°SR. 35-45°SR, mixed evenly according to the mass ratio of 1:1, then added polygalactomannose hemicellulose, the addition amount was 0.05-0.1% of the absolute dry weight, to obtain the paste for printing layer; The pulp of galactomannose hemicellulose and polygalactomannose hemicellulose added is made and dried, and printed with ink after paper is formed. The drying time of the ink is tested, and the printed ink is tested by pressing with a paper towel. The time after wiping without fading is the i...

Embodiment 3

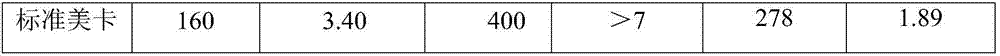

[0052] Printing layer paper pulp: put the original coniferous wood and original broad-leaved wood into the pulper used in the 3.7M continuous hydraulic pulper to pulverize the raw materials, and control the concentration of wood pulp fiber raw materials to 4.0%. The primary pulp of leaf wood pulp and broad-leaved wood pulp is added to beating with a conical mill, and further diluted and beating. The concentration of the obtained fine pulp is 2%. 0.05% of the absolute dry weight to obtain the paste for the printing layer,

[0053] Sandwich layer pulp: the recycled office mixed waste paper is directly put into the pulper used, which is a 3.7M continuous hydraulic pulper, and the raw materials are dissociated, and the concentration of the wood pulp fiber raw material is controlled to 4.0%. The obtained Put the domestic waste paper pulp into the high-concentration slag remover, and first settling sand and coarse sieving to remove impurities under high concentration; remove the sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com