Method for washing meta-aramid fibrid

A kind of aramid fiber and washing method technology, which is applied to the washing field of meta-aramid fiber, can solve the problems of high cost of recycling energy consumption, large washing water equivalent, speeding up the replacement rate of chlorinated salt washing, and the like. The effect of reducing the energy consumption of solvent recovery, increasing the penetration rate and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

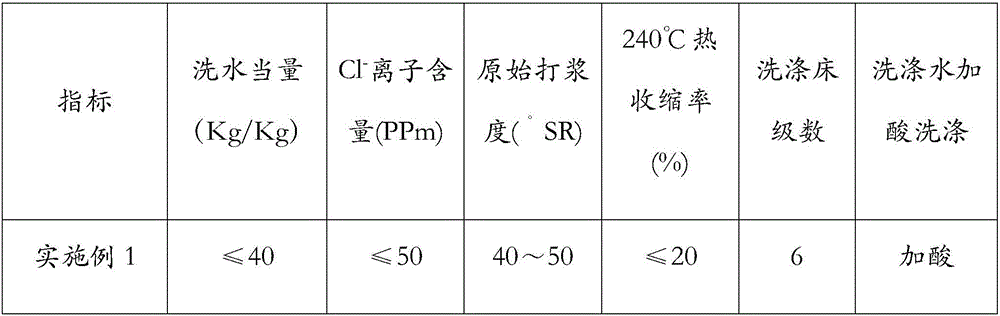

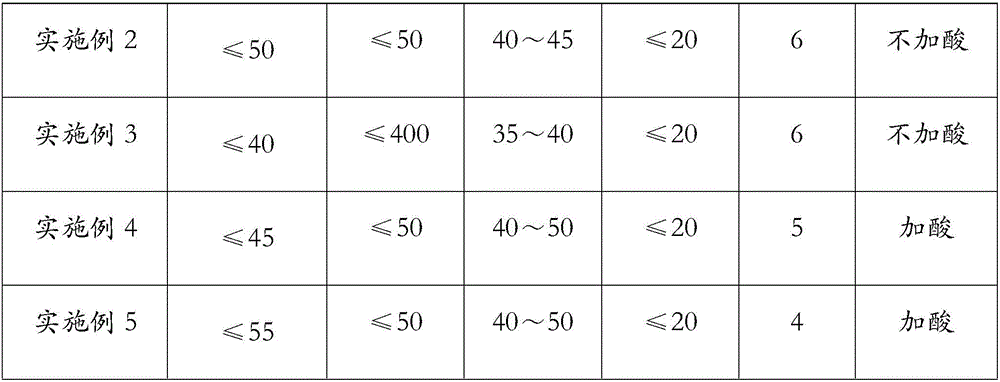

Embodiment 1

[0024] (1) Prepare sedimentation fiber suspension: 20~100m 3 / batch, mass percentage content 0.1 ~ 1%.

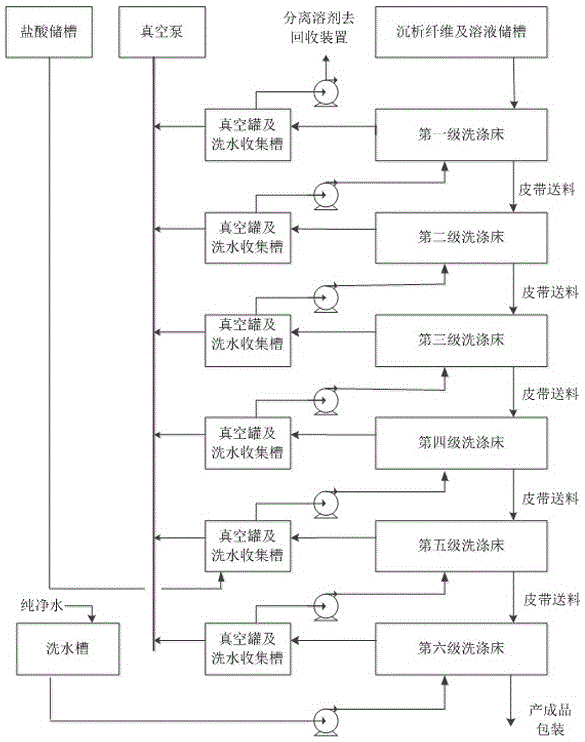

[0025] (2) Pass the precipitated fiber suspension into the first-stage washing bed, spray the washing water from the second-stage washing water collection tank on the surface of the moving filter screen, suck the washing water and solution from the bottom of the filter screen, and pass through the soda water The solution collected by the separation tank is sent to the solvent recovery device; washing water equivalent: ≤40Kg / Kg (dry basis); operating pressure: 100KPa~20KPa (absolute pressure);

[0026] (3) The fibers washed by the first stage are transported to the second stage washing bed, sprayed with the washing water of the third stage washing water collection tank, sucked the washing water, enter the separation tank for steam-water separation, and the collected washing water is transferred to Second stage washing water collection tank; washing water equivalent: ≤40Kg / ...

Embodiment 2

[0034] (1) Prepare sedimentation fiber suspension: 20~100m 3 / batch, mass percentage content 0.1 ~ 1%.

[0035] (2) Pass the precipitated fiber suspension into the first-stage washing bed, spray the washing water from the second-stage washing water collection tank on the surface of the moving filter screen, suck the washing water and solution from the bottom of the filter screen, and pass through the soda water The solution collected by the separation tank is sent to the solvent recovery device; washing water equivalent: ≤50Kg / Kg (dry basis); operating pressure: 100KPa~20KPa (absolute pressure);

[0036] (3) The fibers washed by the first stage are transported to the second stage washing bed, sprayed with the washing water of the third stage washing water collection tank, sucked the washing water, enter the separation tank for steam-water separation, and the collected washing water is transferred to Second stage washing water collection tank; washing water equivalent: ≤50Kg / ...

Embodiment 3

[0044] (1) Prepare sedimentation fiber suspension: 20~100m 3 / batch, mass percentage content 0.1 ~ 1%.

[0045] (2) Pass the precipitated fiber suspension into the first-stage washing bed, spray the washing water from the second-stage washing water collection tank on the surface of the moving filter screen, suck the washing water and solution from the bottom of the filter screen, and pass through the soda water The solution collected by the separation tank is sent to the solvent recovery device; washing water equivalent: ≤40Kg / Kg (dry basis); operating pressure: 100KPa~20KPa (absolute pressure);

[0046] (3) The fibers washed by the first stage are transported to the second stage washing bed, sprayed with the washing water of the third stage washing water collection tank, sucked the washing water, enter the separation tank for steam-water separation, and the collected washing water is transferred to Second stage washing water collection tank; washing water equivalent: ≤40Kg / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com