Activating method of cellulose pulp

A technology of cellulose pulp and activation method, which is applied in the field of preparation of cellulose fiber by solvent method, can solve the problems of physical hazards for operators, high investment, large energy consumption, etc., achieve improved reaction performance, save production costs, and improve utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

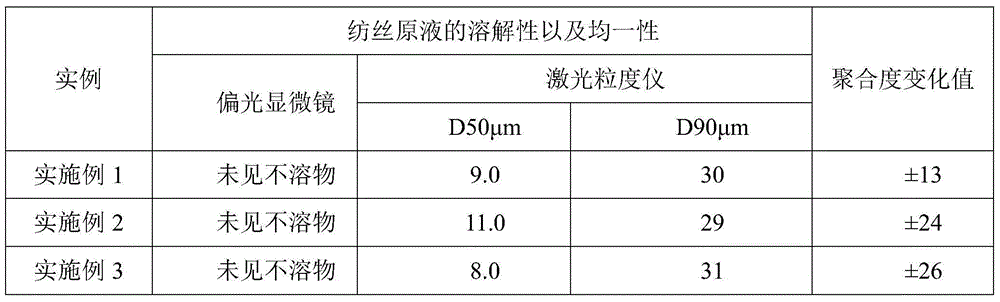

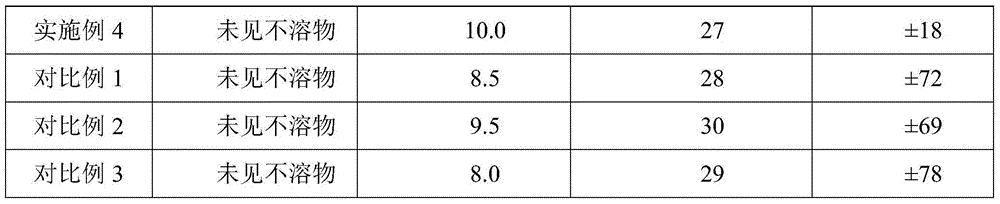

Examples

Embodiment 1

[0041] A kind of activation method of cellulose pulp, select the wood pulp of degree of polymerization 550 as selection material, pretreatment steps are as follows:

[0042] 1. Add 1 / 2 volume of activation water to the medium-concentration hydraulic pulper, the water temperature is 55-60°C, and add formic acid according to the ratio of formic acid: activation water = 1:100;

[0043] 2. According to the weight ratio of activation water:pulp=100:5, put the pulp into the pulper for activation, and activate the pulp for 60 minutes, keep stirring, and the stirring frequency is 40Hz;

[0044] 3. After the pressing step and the crushing step, the cellulose content of the pretreated pulp is 45%, and the cellulose crushing degree is 260g / L;

[0045] 4, dissolving step, the pulp obtained through pretreatment and NMMO+H 2 O (the concentration of NMMO in the system is about 85%) mixed, the excess water is removed by heating or vacuuming, the vacuum degree is -5kpa, the temperature is 110...

Embodiment 2

[0047] A kind of activation method of cellulose pulp, select the wood pulp of degree of polymerization 1000 as selection material, pretreatment steps are as follows:

[0048] 1. Add 1 / 2 volume of activation water to the medium-consistency hydraulic pulper, the water temperature is 25-30°C, and add sodium hydroxide according to the proportion of sodium hydroxide: activation water = 1:200;

[0049] 2. According to the weight ratio of activation water: pulp = 100:5, add the pulp into the pulper for activation, and activate the pulp for 15 minutes;

[0050] 3. After the pressing step and the crushing step, the cellulose content of the pretreated pulp is 50%, and the cellulose crushing degree is 260g / L;

[0051] 4, dissolving step, the pulp obtained through pretreatment and NMMO+H 2 O (the concentration of NMMO in the system is about 82%) mixed, the excess water is removed by heating or vacuuming, the vacuum degree is -6kpa, the temperature is 110°C, the cellulose first swells and...

Embodiment 3

[0053] A kind of activation method of cellulose pulp, select the wood pulp of degree of polymerization 500 as selection material, pretreatment steps are as follows:

[0054] 1. Add 1 / 2 volume of activation water to the medium-consistency hydraulic pulper, and the water temperature is 45-50°C;

[0055] 2. According to the weight ratio of activation water: pulp = 100:5, add the pulp into the pulper for activation, and activate the pulp for 30 minutes;

[0056] 3. After the pressing step and the crushing step, the cellulose content of the pretreated pulp is 45%, and the cellulose crushing degree is 260g / L;

[0057] 4, dissolving step, the pulp obtained through pretreatment and NMMO+H 2 O (the concentration of NMMO in the system is about 85%) mixed, the excess water is removed by heating or vacuuming, the vacuum degree is -5kpa, the temperature is 110°C, the cellulose first swells and then dissolves, and finally an amber uniform and transparent spinning solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pulverization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com