Preparation method of water-based desulfurizing agent used for high sulfur crude oil

A desulfurizer, water-based technology, used in the petroleum industry, processing hydrocarbon oil, refining hydrocarbon oil, etc., can solve the problems of irreversible desulfurization reaction, incomplete desulfurization, etc. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

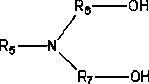

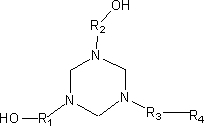

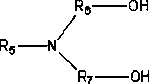

[0024] Add 15 parts of 1,3,5-tris(hydroxyethyl)-hexahydro-s-triazine, 15 parts of 1,3-hydroxyethyl-5-aminoethyl-triazine, 10 parts of diethanolamine ( DEA), 8 parts of methanol, 47.77 parts of water, stirred for 30 minutes, then added 2 parts of sodium succinate sulfonate, 2 parts of acetic acid, 0.2 parts of sodium acetate, 0.03 parts of polyether defoamer while stirring, and then added After stirring for 30 minutes evenly, the product was obtained.

Embodiment 2

[0026] Add 15 parts of 1,3,5-tris(hydroxyethyl)-hexahydro-s-triazine, 15 parts of 1,3-hydroxyethyl-5-aminoethyl-triazine, 10 parts of methyl di Ethanolamine (MDEA), 10 parts of methanol, 45.77 parts of water, stirred for 30 minutes, then added 2 parts of sodium succinate sulfonate, 2 parts of acetic acid, 0.2 parts of sodium acetate, 0.03 parts of polyether defoamer while stirring, and the addition was completed After stirring for 30 minutes evenly, the obtained product was obtained.

Embodiment 3

[0028] Add 15 parts of 1,3,5-tris(hydroxyethyl)-hexahydro-s-triazine, 10 parts of 1,3-hydroxyethyl-5-aminoethyl-triazine, 10 parts of methyl di Ethanolamine (MDEA), 8 parts of methanol, 3 parts of water, stirred for 30 minutes, then added 1.5 parts of sodium succinate sulfonate, 1.5 parts of acetic acid, 0.15 parts of sodium acetate, 0.02 parts of polyether defoamer while stirring, after the addition was completed After stirring for 30 minutes evenly, the obtained product was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com