Preparation method of color semi-transparent fruit bag paper

A translucent, fruit bag paper technology, applied in pulp beating method, pulp beating/refining method, special paper, etc., can solve the problem of high dye cost, achieve uniform color, reduce raw material cost, and reduce cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

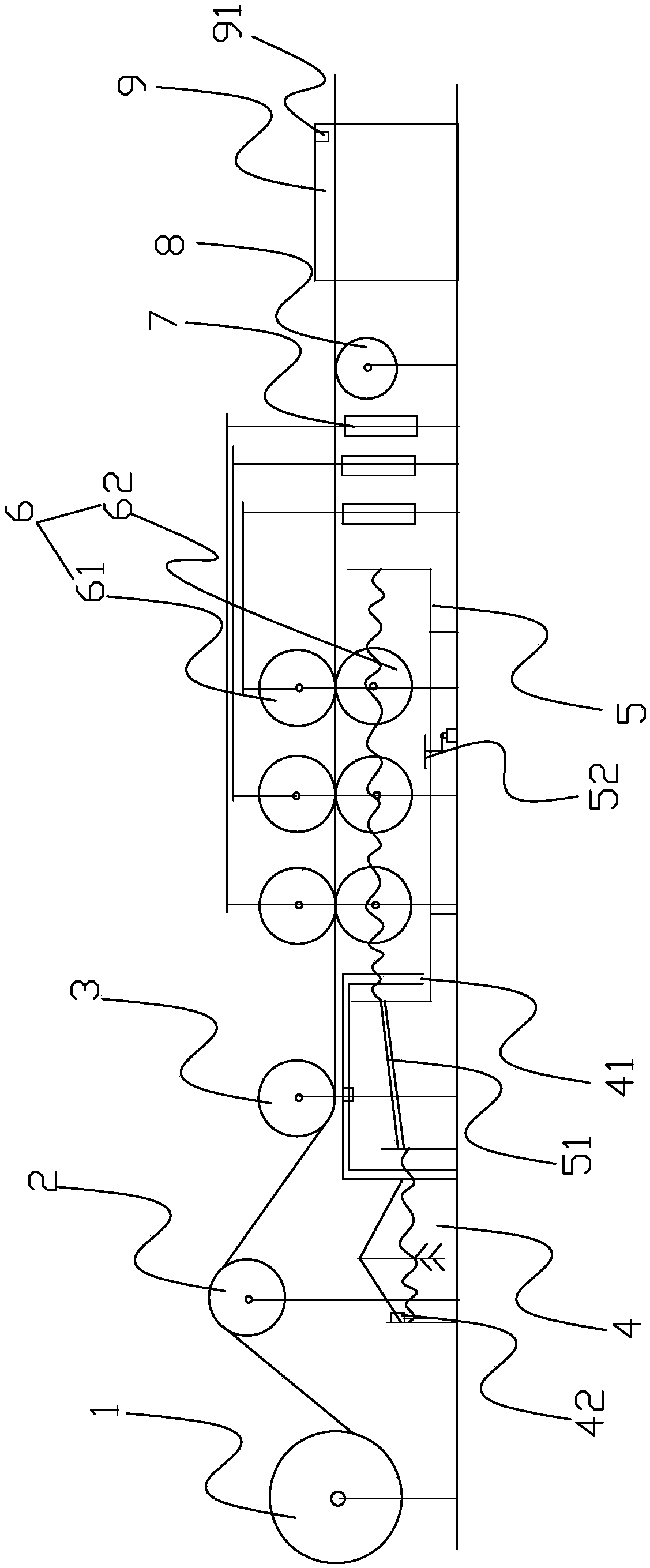

Image

Examples

Embodiment 1

[0026] A preparation method for colored translucent fruit bag paper, comprising the following steps:

[0027] 1) beating, get 25 parts by weight of hardwood raw materials, 35 parts by weight of softwood raw materials, 15 parts by weight of deinked pulp, and 10 parts by weight of bagasse raw materials for beating with a hydraulic disintegrator respectively to obtain slurry respectively, when beating Adjust the pH value to 5 with acetic acid, mix in 0.05 parts by weight of softening agent and 0.05 parts by weight of beating enzyme, and control the degree of beating at 70°SR; the beating enzyme is composed of the following mass fractions: 5% cellulase , 4% hemicellulase, 4% xylanase, 4% phospholipase, 0.5% Span 60, 0.02% potassium sorbate, 1% laccase, and the balance is deionized water;

[0028] The enzyme activity of the cellulase in the beating enzyme preparation is 800U / mL, the enzyme activity of hemicellulase is 300U / mL, the enzyme activity of xylanase is 200U / mL, and the enz...

Embodiment 2

[0037] A preparation method for colored translucent fruit bag paper, comprising the following steps:

[0038] 1) beating, get 28 parts by weight of hardwood raw materials, 40 parts by weight of softwood raw materials, 18 parts by weight of deinked pulp, and bagasse raw materials of 15 parts by weight for beating with a hydraulic disintegrator respectively to obtain slurry respectively, when beating Adjust the pH value to 5.5 with acetic acid, mix in 0.2 parts by weight of softening agent and 0.08 parts by weight of beating enzyme, and control the degree of beating at 75°SR; the beating enzyme is composed of the following mass fractions: 8% cellulase , 5% hemicellulase, 5% xylanase, 4.5% phospholipase, 0.8% Span 60, 0.03% potassium sorbate, 1.5% laccase, and the balance is deionized water;

[0039] The enzyme activity of the cellulase in the described beating enzyme preparation is 1200U / mL, the enzyme activity of hemicellulase is 400U / mL, the enzyme activity of xylanase is 300U...

Embodiment 3

[0047] A preparation method for colored translucent fruit bag paper, comprising the following steps:

[0048] 1) beating, get the hardwood raw material of 30 weight parts, the coniferous wood raw material of 50 weight parts, the deinked pulp of 20 weight parts, the bagasse raw material of 20 weight parts respectively hydraulic cracker beating, respectively obtain slurry, when beating Adjust the pH value to 6 with acetic acid, mix in 0.5 parts by weight of softening agent and 0.1 parts by weight of beating enzyme, and control the beating degree at 80°SR; the beating enzyme is composed of the following mass fractions: the beating enzyme is composed of the following mass fraction Composition of fractions: 10% cellulase, 6% hemicellulase, 6% xylanase, 5% phospholipase, 1% Span 60, 0.03% potassium sorbate, 2% of laccase, and the balance is deionized water;

[0049] The enzyme activity of the cellulase in the described beating enzyme preparation is 1500U / mL, the enzyme activity of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com