Preparation method of double-sided high-gloss tissue paper

A technology of high-gloss, thin-sheet paper, applied in the field of papermaking, to achieve good peelability, obvious enhancement effect, and glossy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

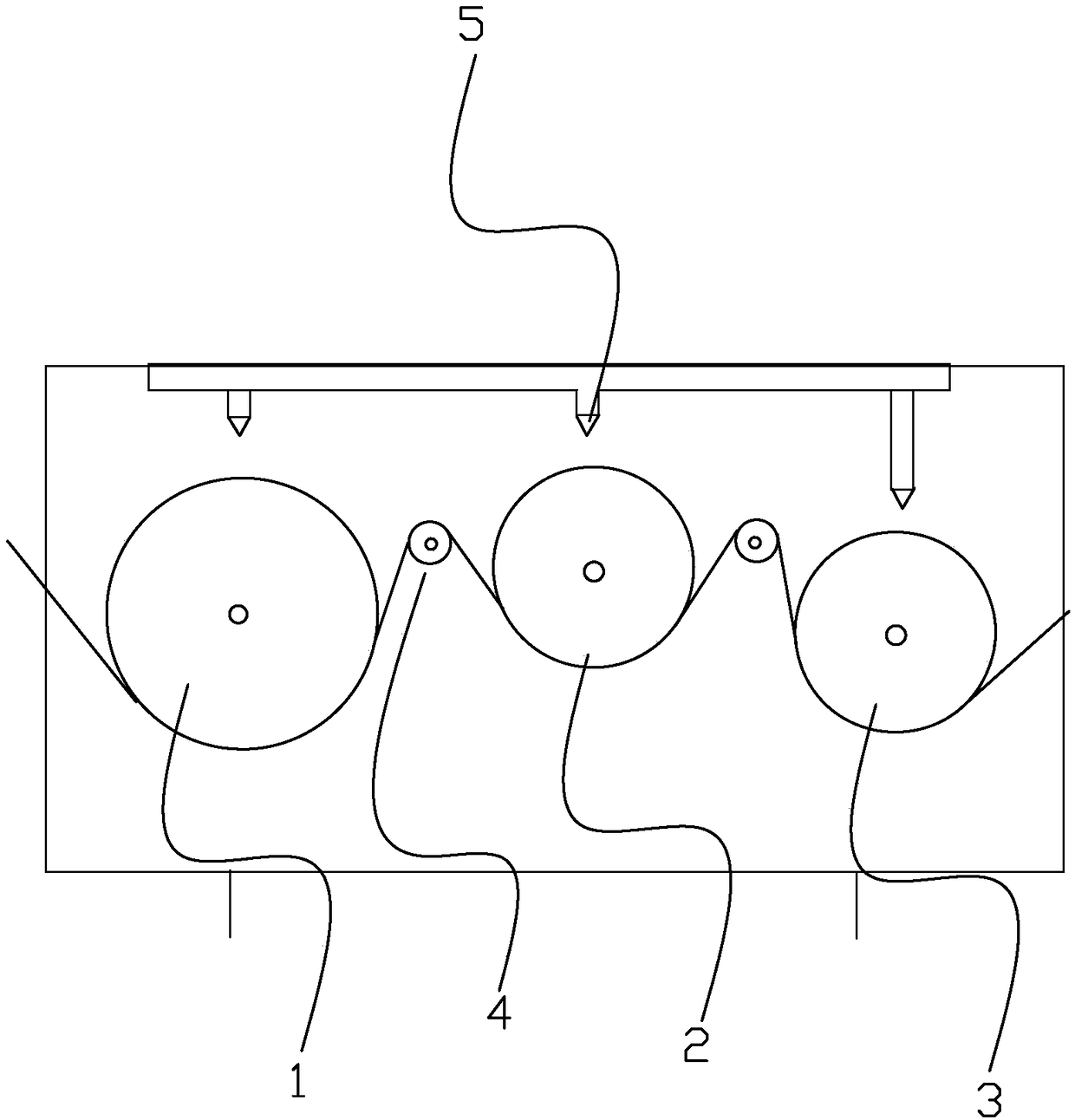

Image

Examples

Embodiment 1

[0021] A method for preparing double-sided high-gloss tissue paper, the steps are:

[0022] 1) Pulping: the coniferous wood pulp is disintegrated by a pulper, and then beaten through the knocking pool, the disc mill and the knocking pool in turn, and the deinked waste paper pulp is beaten separately; the beating degree of the above two pulps is 70°SR ; The above two kinds of slurry are blended according to the weight ratio of 1:1, the concentration is adjusted, and a papermaking auxiliary is added; the papermaking auxiliary is composed of the following raw materials in parts by weight: 10 parts of guar gum, quaternary ammonium starch 25 parts, 5 parts of alum, 10 parts of melamine, 50 parts of high-gloss paraffin, the amount of the auxiliary agent is 3% of the weight of the slurry; when guar gum is used as a papermaking auxiliary agent, it can improve the strength of the paper sheet, reduce the formation of gray spots and improve Paper evenness, but its disadvantage is that it...

Embodiment 2

[0026] A method for preparing double-sided high-gloss tissue paper, the steps are:

[0027] 1) Pulping: the coniferous wood pulp is disintegrated by a pulper, and then beaten through the knocking pool, the disc mill and the knocking pool in turn, and the deinked waste paper pulp is beaten separately; the beating degree of the above two pulps is 75°SR ; The above two kinds of slurry are blended according to the weight ratio of 1:3, the concentration is adjusted, and the papermaking auxiliary agent is added; the papermaking auxiliary agent is composed of the following raw materials in parts by weight: 15 parts of guar gum, quaternary ammonium starch 20 parts, 1 part of alum, 15 parts of melamine, 60 parts of high-gloss paraffin, and the auxiliary agent consumption is 10% of the slurry weight;

[0028] 2) Desanding: The above-mentioned mixed slurry is desandered through the forebay, the high level box, the intermediate tank, the desandering pump and the desandering device success...

Embodiment 3

[0031] A method for preparing double-sided high-gloss tissue paper, the steps are:

[0032] 1) Pulping: the coniferous wood pulp is disintegrated by a pulper, and then it is beaten through the knocking pool, the disc mill and the knocking pool in turn, and the deinked waste paper pulp is beaten separately; the beating degree of the above two pulps is 73°SR ; The above two kinds of slurry are mixed according to the weight ratio of 1:2, the concentration is adjusted, and papermaking auxiliary is added; the papermaking auxiliary is composed of the following raw materials in parts by weight: 12 parts of guar gum, quaternary ammonium starch 23 parts, 3 parts of alum, 12 parts of melamine, 55 parts of high-gloss paraffin, and the auxiliary agent consumption is 6% of slurry weight;

[0033] 2) Desanding: The above-mentioned mixed slurry is desandered through the forebay, the high level box, the intermediate tank, the desandering pump and the desandering device successively;

[0034]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com