Antibacterial ramie fiber reinforced polypropylene composite material and preparation method thereof

The technology of ramie fiber and composite material is applied in the field of antibacterial ramie fiber reinforced polypropylene composite material and its preparation, which can solve the problems affecting the application field of ramie fiber reinforced polypropylene material, the discoloration of the surface of the composite material, and the acceleration of mold growth, etc., so as to achieve high efficiency. Broad-spectrum killing and inhibition of various microorganisms, improving mechanical locking, and reducing hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

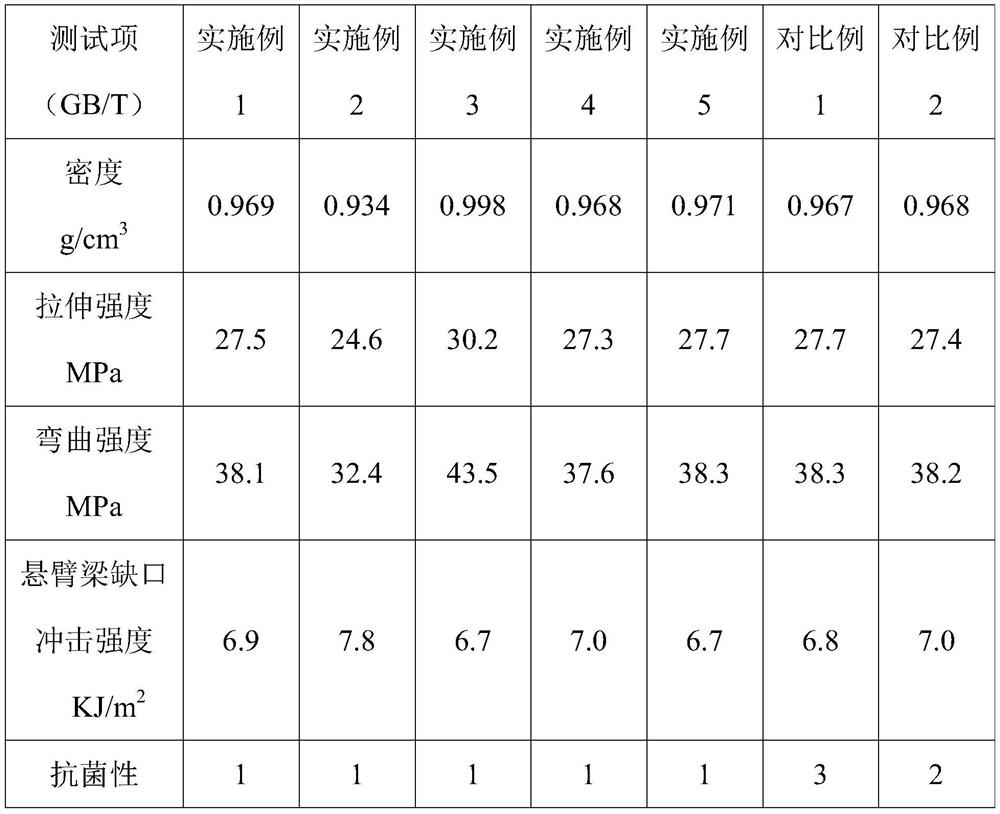

Examples

Embodiment 1

[0023] Preparation of modified ramie fiber: add ramie fiber to 10% sodium hydroxide solution, the ratio of solid to liquid g / mL is 1:10, soak at 50°C for 24 hours, and then transfer to permanganate with a concentration of 0.04% Oxidation treatment in potassium solution, the solid-liquid ratio g / mL is 1:10, and the treatment is at room temperature for 2 minutes, then the oxidized ramie fiber is added to 0.1 g / mL PHMG aqueous solution, the solid-liquid ratio g / mL is 1 : 10, fully stirred, reacted at normal temperature for 6h, cleaned up, and finally obtained ramie fibers grafted with PHMG, which were fully dried in an oven for subsequent use.

[0024] The preparation of the antibacterial ramie fiber reinforced polypropylene composite material is as follows: Weigh 75 parts of PP model K9017H, 4 parts of compatibilizer CA100, 0.5 part of antioxidant (antioxidant 1010: 0.2 part, antioxidant 168: 0.3 part), 0.5 part of PE wax, 1 part of HALS 944, they are added in the middle and low...

Embodiment 2

[0026] The preparation of modified ramie fiber is the same as in Example 1.

[0027] The preparation of the antibacterial ramie fiber-reinforced polypropylene composite material, compared with Example 1, differs only in that the amount of modified ramie fiber added is 10 parts.

Embodiment 3

[0029] The preparation of modified ramie fiber is the same as in Example 1.

[0030] The preparation of the antibacterial ramie fiber reinforced polypropylene composite material, compared with Example 1, differs only in that the added amount of the modified ramie fiber is 30 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com