Novel environment-friendly biological knot and use method thereof

A bio-fouling, environmentally friendly technology, applied in earth-moving drilling, production fluids, wellbore/well components, etc., to achieve the effect of slow dissolution and maintaining plugging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

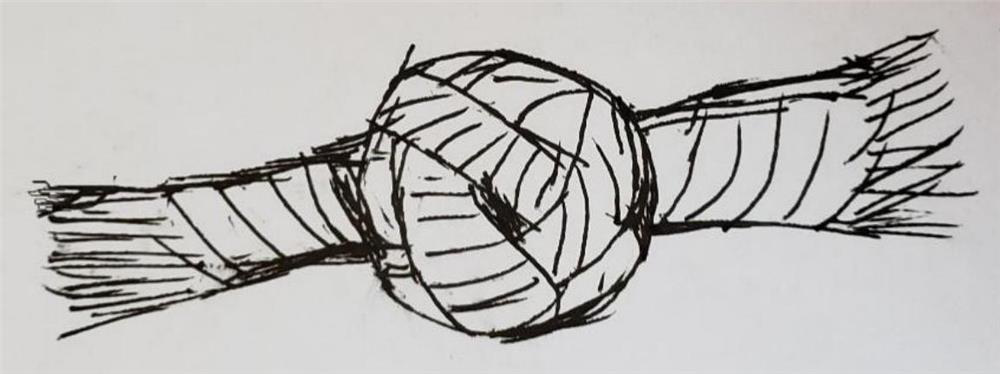

Embodiment 1

[0062] Select a degradable polyglycolic acid material with a tensile strength of 120MPa and a molecular weight of 1-100w, spin the polyglycolic acid material, weave it into a rope, and then use the polyglycolic acid rope to make a knot with a diameter of 17-20mm , The diameter of the knot can be adjusted according to the hole to be blocked, and the two ends of the knot leave a braided wire with a length of 20-25mm, and the novel environmentally friendly biological knot proposed by the present invention can be obtained.

[0063] The dissolution test was carried out on the new environmentally friendly biological knot, the test temperature was 90°C, and the medium was clean water. Place the new environmentally friendly biological knot in the reagent bottle.

[0064] Test results: Under the condition of 90 ℃ and clear water, it began to dissolve on the 4th day, the knot part was completely broken on the 6th day, and completely dissolved on the 11th day. After drying and weighing,...

Embodiment 2

[0066] Select a degradable polyglycolic acid material with a tensile strength of 120MPa and a molecular weight of 1-100w, spin the polyglycolic acid material, weave it into a rope, and then use the polyglycolic acid rope to make a knot with a diameter of 17-20mm The two ends of the knot leave a braided wire with a length of 20-25mm, and the novel environment-friendly biological knot proposed by the present invention can be obtained.

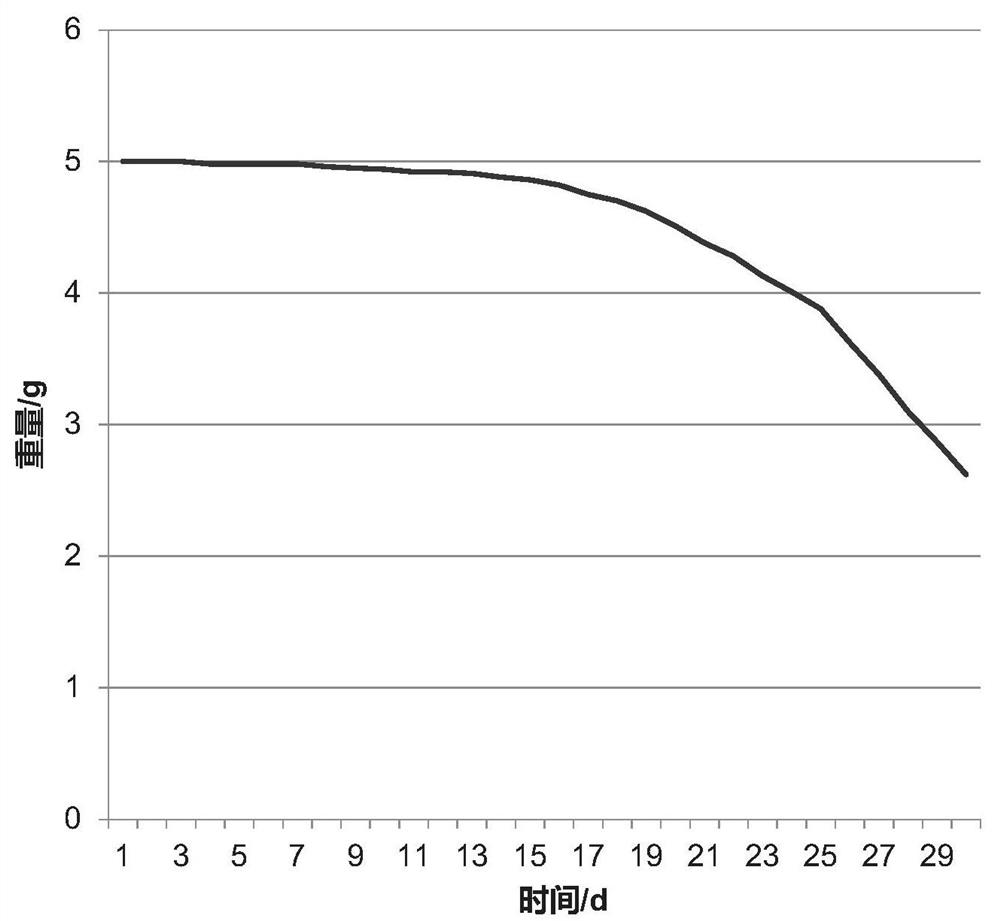

[0067] The new environment-friendly biological knot is mixed with the acrylamide modified copolymer as a strengthening agent, and the dissolution test of the new environment-friendly bio-knot is carried out. The test temperature is 90°C, and the medium is clean water. Place the new environmentally friendly biological knot in the reagent bottle.

[0068] For the results of the dissolution test, see figure 2 , the results show that the new environmentally friendly bio-concrete dissolves slowly in the enhancer, can maintain effective sealing for 2...

Embodiment 3

[0070] Select a degradable polyglycolic acid material with a tensile strength of 120MPa and a molecular weight of 1-100w, spin the polyglycolic acid material, weave it into a rope, and then use the polyglycolic acid rope to make a knot with a diameter of 17-20mm The two ends of the knot leave a braided wire with a length of 20-25mm, and the novel environment-friendly biological knot proposed by the present invention can be obtained.

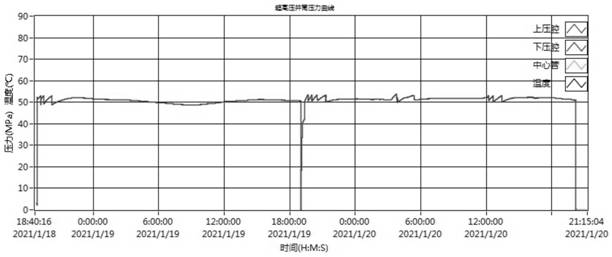

[0071] Carry out a pressure test to verify the pressure-bearing performance of the new environmentally friendly bio-junction in the strengthening liquid.

[0072] Test overview: The maximum outer diameter of the new environmentally friendly biological knot is 19.42mm, the smallest outer diameter is 15.36mm, and the hole diameter is 9mm.

[0073] Connect the test tooling, add 1 liter of jelly strengthening solution, let stand for 30 minutes, and then add water;

[0074] Heating up to 90°C, constant temperature for 2 hours, pressure at 52.26MPa, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com