Rotary drum type hydraulic power disintegrator

A drum type, hydraulic technology, applied in the field of papermaking equipment, can solve the problems of shortening waste paper fiber length, waste paper fiber damage, unfavorable waste paper fiber recycling, etc., to achieve length and strength retention, mild pulping, and lighten the burden Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

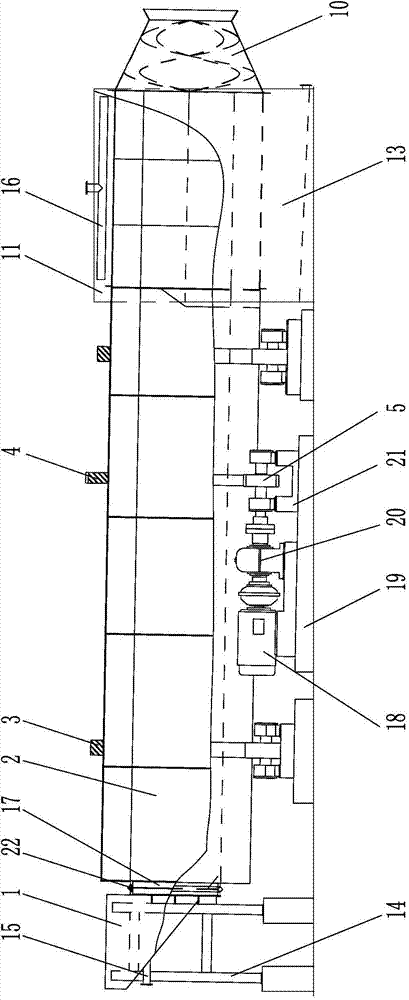

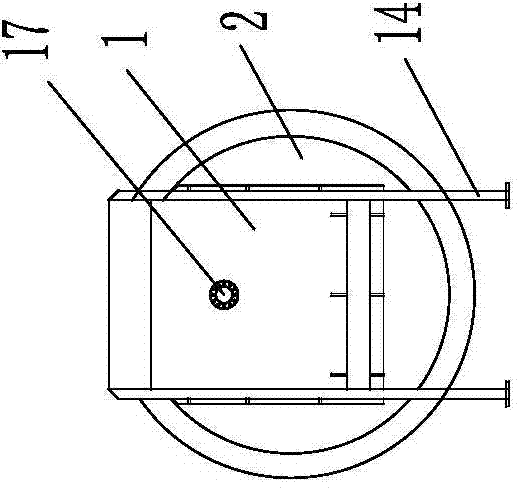

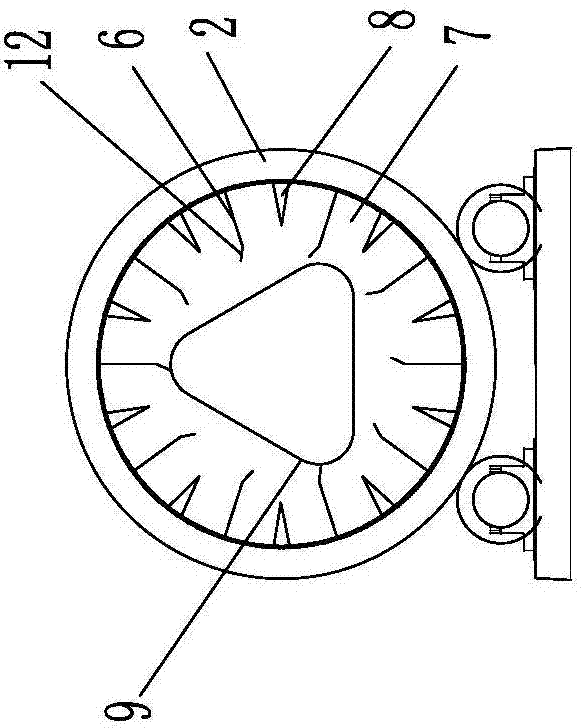

[0020] like figure 1 , 2 , 3, 4, 5, and 6, the rotary drum hydraulic disintegrator includes an upper hopper 1, a rotary drum 2, a rotary drum transmission device, a supporting wheel device, and a sealing device. A circle of large supporting rollers 3, a circle of large gears 4 is arranged on the outer side wall of the drum 2 between the two large supporting rollers 3, and the two large supporting rollers 3 are respectively located on the supporting roller device at the bottom of the drum 2, so that the The discharge port is slightly lower than the feed port, the large gear 4 meshes with the pinion gear 5 on the drum transmission device at the bottom of the drum 2, and the drum transmission device includes a motor 18, a motor base 19, a transmission shaft 20, a pinion gear 5, Gear seat 21, motor 18 and gear seat 21 are respectively arranged on motor seat 19, pinion 5 is arranged on gear seat 21, one end of pinion 5 penetrates gear seat 21 and is connected with the rotating sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com