Switching method and switching system for steel wire rope in automobile crash test traction equipment

A technology of crash test and traction equipment, applied in the field of automobile crash test, can solve the problems of low breaking strength, easy detachment of new ropes when placed, shortening the life of steel wire ropes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

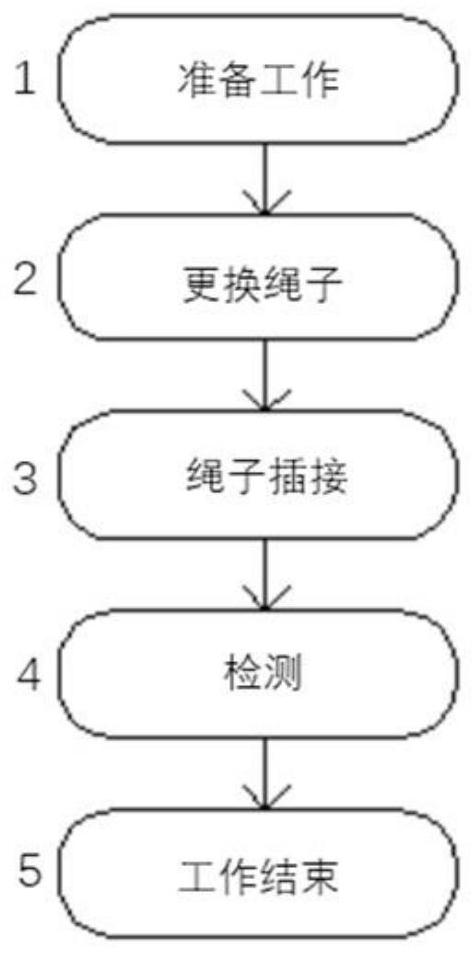

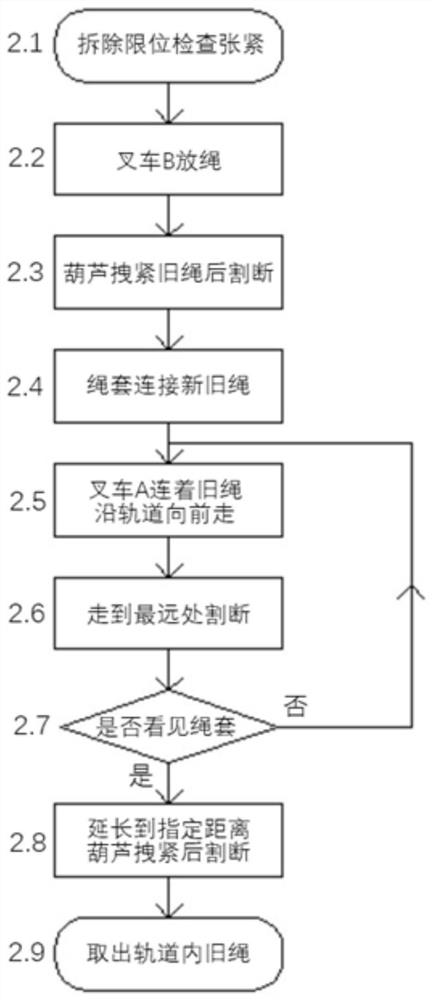

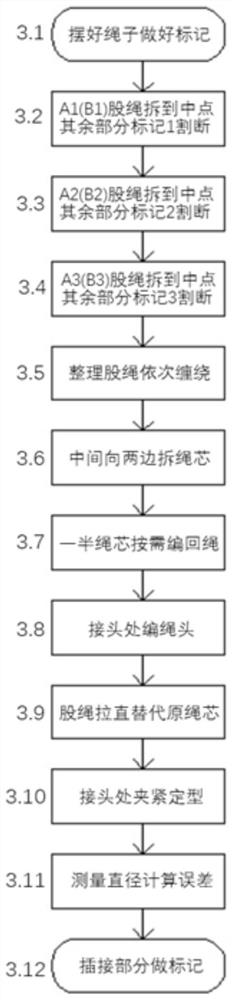

[0079] A method for switching steel wire ropes in traction equipment for automobile crash tests, such as figure 1 As shown, it includes changing the rope, rope insertion and detection in turn, wherein changing the rope includes the following steps (such as figure 2 shown):

[0080] (1) Prepare the new steel wire rope (the specifications of the steel wire rope required by the automobile crash test equipment are generally 16mm in diameter, 6 strands of metal wire strand core, large strands are twisted to the right, and small strands are twisted to the left), and ensure that the length is long enough (if it needs to be replaced) If the wire rope length is 600 meters, you need at least 650-700 meters in length).

[0081] (2) Remove the electronic limit device of the heavy hammer of the steel wire rope. The function of the heavy hammer is to ensure that the long steel wire rope will not jump out of the underground track during operation. Therefore, it is convenient to remove this...

Embodiment 2

[0109] Such as Figure 5 As shown, this embodiment provides a steel wire rope switching system in the traction equipment for automobile crash test, including: a fixing device, a moving device, a new steel wire rope 3 and a truncated old steel wire rope 4, and the truncated old steel wire rope 4 is arranged underground In the track, the truncated old wire rope 4 includes a front end and a rear end (not shown);

[0110] The mobile device and the fixed device are parked on the ground along the direction of the underground track, the mobile device is parked before the fixed device, a new steel wire rope is installed on the fixed device, the free end of the new steel wire rope 3 is connected to the front end, and the mobile device is connected to the fixed device. connected to the back end.

[0111] The fixing device is a forklift A1, and the moving device is a forklift B2;

[0112] The free end of the new steel wire rope 3 and the outer side of the front end are provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com