Method for producing high-strength homogenized tobacco material by thick pulp papermaking method

A papermaking method and high-strength technology, which is applied in the field of preparation of new heat-not-burn tobacco products, achieves the effects of large load capacity, improved processing performance, and improved processing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

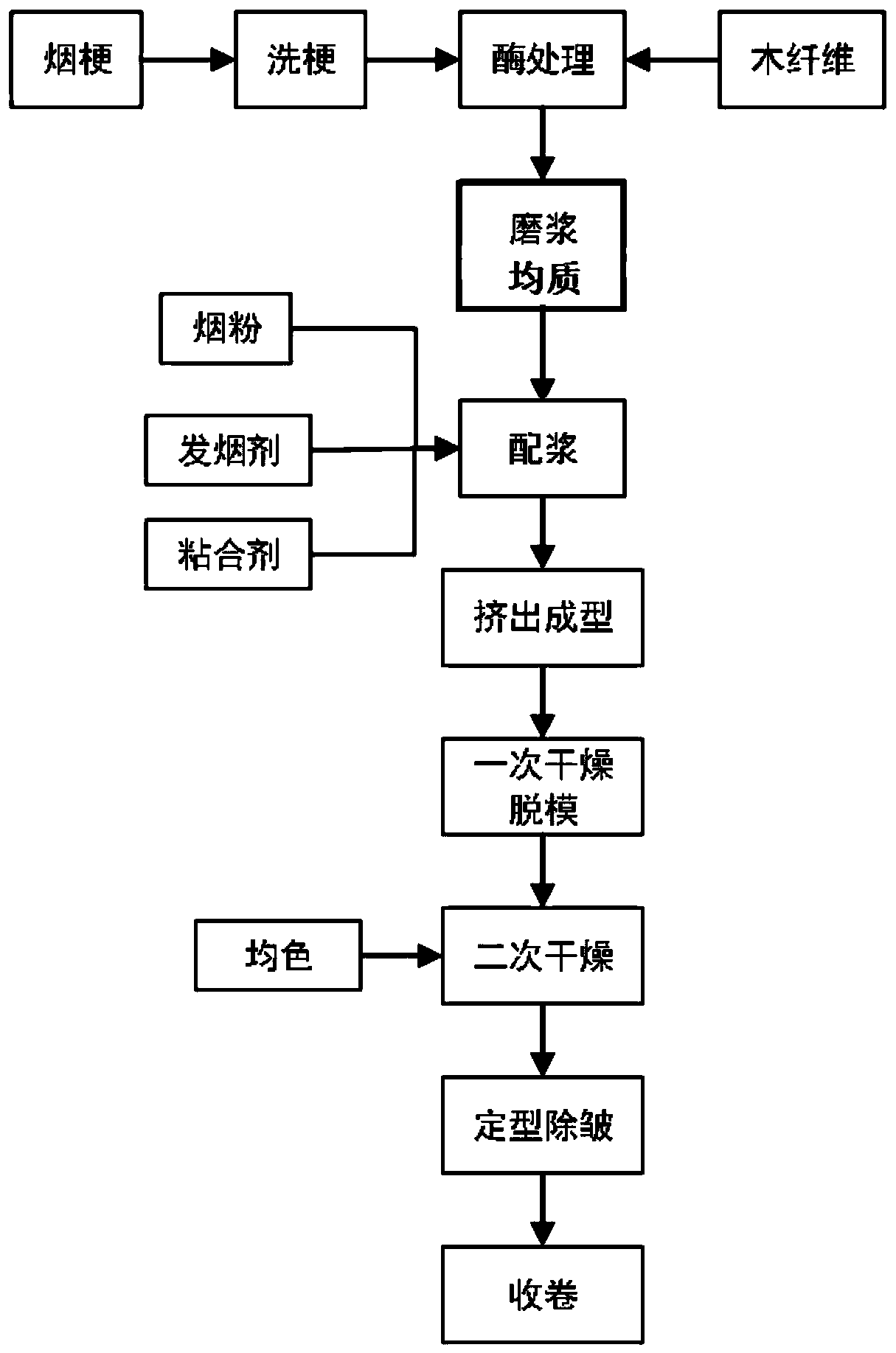

[0032] see figure 1 A method for producing high-strength homogenized tobacco material by a thick pulp papermaking method, comprising the following steps:

[0033] (1) Mix 70% water-washed tobacco stems with 30% wood fiber according to the mass ratio, and then perform enzyme treatment. The wood fibers are basswood fibers and hemp leaves, and the enzyme preparation used in the enzyme treatment is cellulase, and these raw materials can be purchased on the market. The method of enzyme treatment is as follows: the microwave expanded tobacco stem is used as the carrier of the enzyme preparation, and the microwave expanded tobacco stem loaded with cellulase is loaded into a filter bag by utilizing the characteristics of the microwave expanded tobacco stem, which has good material absorption and is not easy to decompose, and then Put the filter bag into the container where the washed tobacco stems and wood fibers are mixed, keep the filter bag at 40°C-45°C for 40 minutes, and then ta...

Embodiment 2

[0044] A method for producing high-strength homogenized tobacco material by a thick pulp papermaking method, comprising the following steps:

[0045] (1) Mix 60% washed tobacco stem with 40% red pine fiber according to the mass ratio, and then carry out enzyme treatment. The enzyme preparation used in the enzyme treatment is a mixture of hemicellulase and amylase, and these raw materials are commercially available. The method of enzyme treatment is as follows: use microwave expanded tobacco stem as the carrier of enzyme preparation, put the microwave expanded tobacco stem loaded with enzyme preparation into a filter bag, then put the filter bag into a container for mixing washed tobacco stem and wood fiber, After keeping the temperature at 50°C for 30 minutes, take out the filter bag. The expansion degree of the microwave-expanded tobacco stem used is 300-350%, and the dosage of the enzyme preparation is 0.04% of the sum of the mass of the washed tobacco stem and the red pine...

Embodiment 3

[0056] A method for producing high-strength homogenized tobacco material by a thick pulp papermaking method, comprising the following steps:

[0057] (1) Mix 80% water-washed tobacco stems with 20% hemp leaves according to the mass ratio, and then perform enzyme treatment. The enzyme preparation used in the enzyme treatment is α-L-arabinofuranosidase, and these raw materials are commercially available. The method of enzyme treatment is as follows: use microwave expanded tobacco stem as the carrier of enzyme preparation, put the microwave expanded tobacco stem loaded with enzyme preparation into a filter bag, then put the filter bag into a container for mixing washed tobacco stem and hemp leaves, After keeping the temperature at 45°C for 60 minutes, take out the filter bag. The expansion degree of the microwave-expanded tobacco stems used is 300%, and the dosage of the enzyme preparation is 0.045% of the sum of the mass of the washed tobacco stems and hemp leaves.

[0058] (2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com