Hyperbranched polyamidoamine modified plant fiber reinforced polypropylene micro foaming material and preparation method thereof

A plant fiber and polyamidoamine technology, which is applied in the field of hyperbranched polyamidoamine modified plant fiber reinforced polypropylene micro-foaming materials and its preparation, can solve the problems of difficult dispersion, poor compatibility of non-polar polymers, and influence on fiber Comprehensive properties of composite materials and other issues, to achieve the effect of uniform and fine cells, improve compatibility, and fine cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

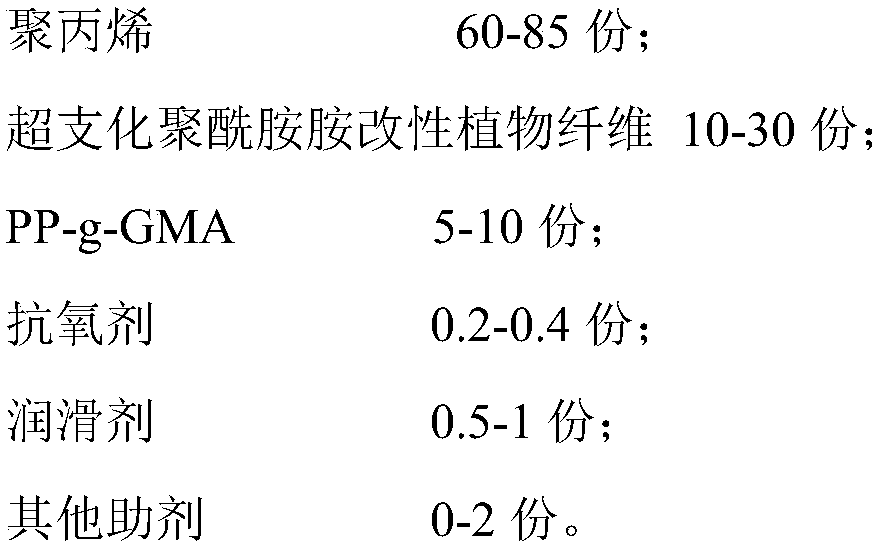

[0033] In this embodiment, the polypropylene composite material is composed of the following raw materials in parts by weight:

[0034]

[0035]

[0036] The hyperbranched polyamidoamine modified plant fiber reinforced polypropylene micro-foaming composite material is composed of 98wt% polypropylene composite material and 2wt% chemical foaming agent.

[0037] Concrete preparation method comprises the following steps:

[0038] (1) Weigh 96 parts of jute fiber and add it to the ethanol aqueous solution with a volume ratio of 90:10, soak at room temperature for 30 minutes, slowly add 4 parts of γ-glycidyl etheroxypropyl trimethoxysilane, heat up to 50-60°C and stir at a constant temperature 24-48h, washed 5 times with dehydrated ethanol, and vacuum-dried the product at 80°C for 24-48h to obtain modified jute fiber;

[0039] (2) Soak the modified jute fiber prepared in step (1) in ethanol for 30min, slowly add 3 parts of hyperbranched polyamidoamine, heat up to 70°C and sti...

Embodiment 2

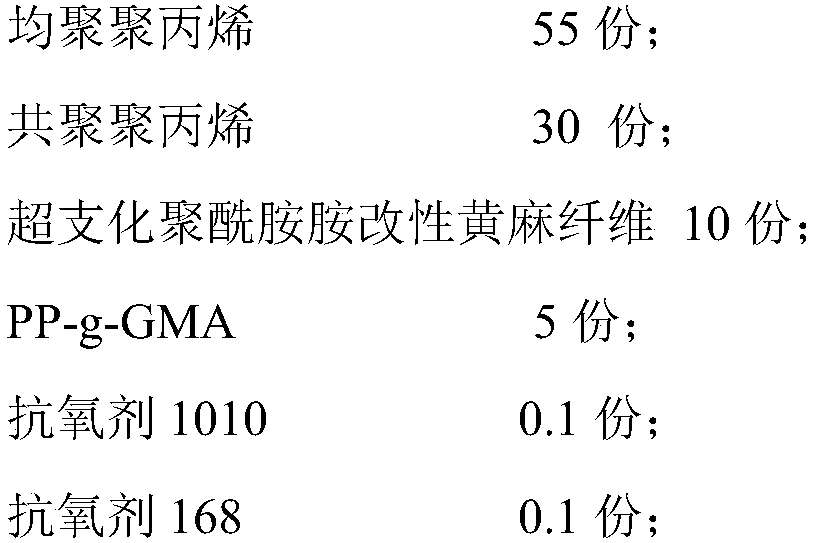

[0043] In this embodiment, the polypropylene composite material is composed of the following raw materials in parts by weight:

[0044]

[0045]

[0046] The hyperbranched polyamidoamine modified plant fiber reinforced polypropylene micro-foaming composite material is composed of 97wt% polypropylene composite material and 3wt% chemical foaming agent.

[0047] Concrete preparation method comprises the following steps:

[0048] (1) Weigh 93 parts of ramie fiber and add it to ethanol water solution with a volume ratio of 90:10, soak at room temperature for 20 minutes, slowly add 7 parts of γ-glycidyl etheroxypropylmethyldiethoxysilane, heat up to 55°C and stir at constant temperature 36h, washed 4 times with dehydrated ethanol, and vacuum-dried the product at 60°C for 24h-48h to obtain modified ramie fibers;

[0049] (2) Soak the modified ramie fiber prepared in step (1) in ethanol for 20 minutes, slowly add 5 parts of hyperbranched polyamidoamine, heat up to 65°C and stir...

Embodiment 3

[0053] In this embodiment, the polypropylene composite material is composed of the following raw materials in parts by weight:

[0054]

[0055]

[0056] The hyperbranched polyamidoamine modified plant fiber reinforced polypropylene micro-foaming composite material is composed of 98wt% polypropylene composite material and 2wt% chemical foaming agent.

[0057] Concrete preparation method comprises the following steps:

[0058] (1) Weigh 90 parts of flax fiber and add it to an ethanol aqueous solution with a volume ratio of 90:10, soak at room temperature for 10 minutes, slowly add 10 parts of γ-glycidyloxypropyltrimethoxysilane, heat up to 50°C and stir at a constant temperature for 24 hours, Washing with dehydrated ethanol for 3 times, vacuum-drying the product at 50°C for 24 hours, finally obtaining modified flax fiber;

[0059] (2) Soak the modified jute fiber prepared in step (1) in ethanol for 10 minutes, slowly add 10 parts of hyperbranched polyamidoamine, heat up ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com