Online mixing injection molding process suitable for carbon fiber automobile part

A technology for auto parts and carbon fibers, which is applied in the field of online mixing and injection molding, can solve the problems of damaged fibers and performance degradation, and achieves the effects of reducing shear force, improving strength, and simple and mature technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

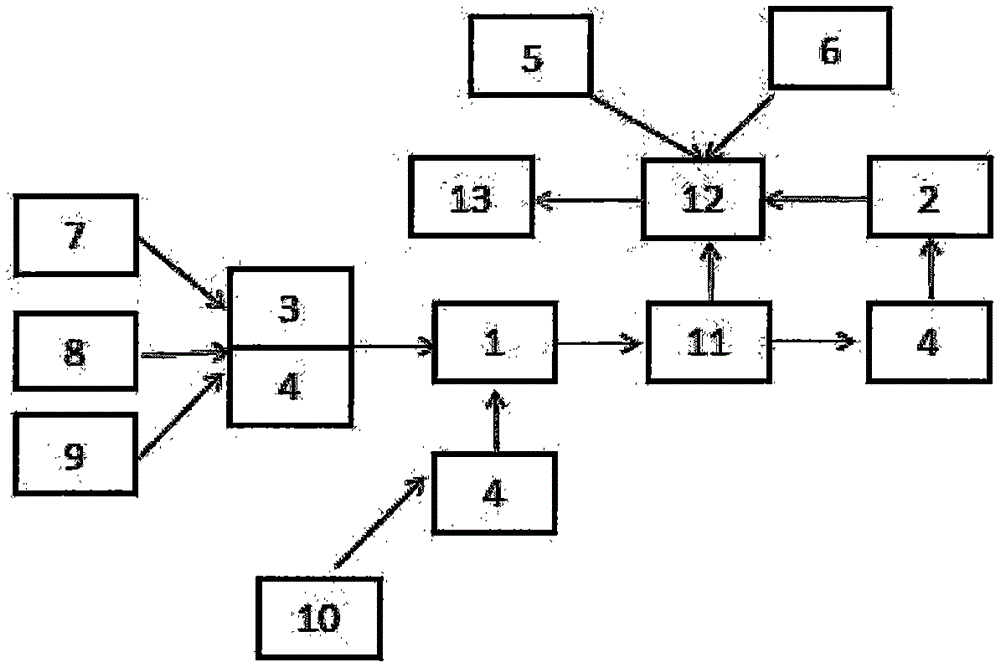

[0011] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0012] see figure 1 , the present invention is an online mixing and injection molding process suitable for carbon fiber auto parts, and the equipment for realizing the process includes: a twin-screw extruder 1, an injection molding machine 2, an automatic feeder 3, and a forced side feeding system 4 , mold temperature machine 5 and chiller 6. It is characterized in that: according to the formula resin system, plastic particles 7, additives 8 and fillers 9 are added to the twin-screw machine 1 through the automatic feeder 3 and the forced side feeding system 4 to carry out mixing and plasticization; In the latter stage, the recycled carbon fiber 10 is added through the forced side feeding system 4, and further mixed and plasticized; the uniforml...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com