Mould with long glass fiber composite material co-extrusion machine opening

A composite material and long glass fiber technology, used in metal processing and other directions, can solve the problems of reinforcement effect, short fiber, and insufficient performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

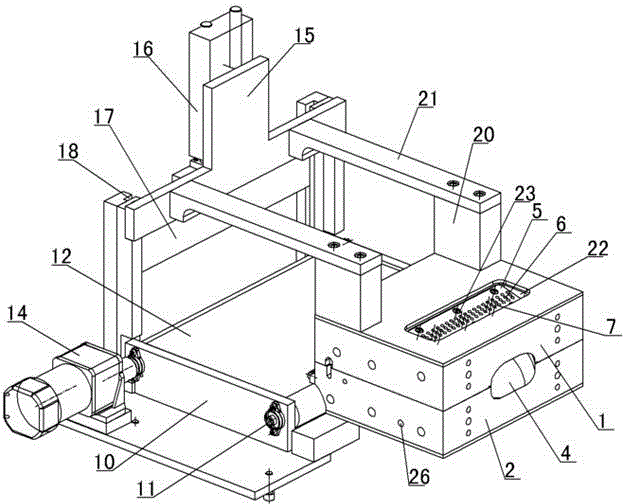

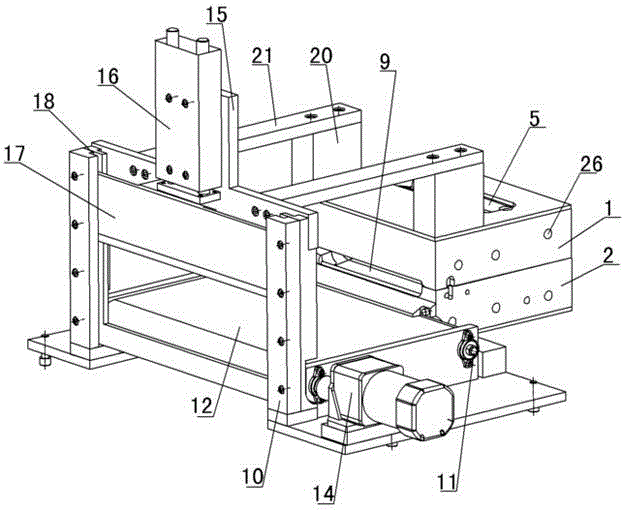

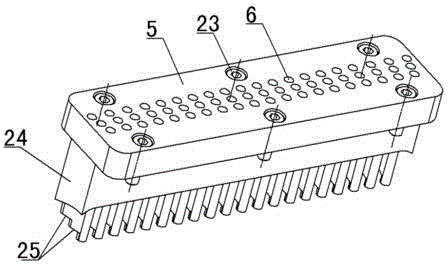

[0011] The invention relates to a co-extruder die with long glass fiber composite materials, such as figure 1 — Figure 4 Shown, comprise upper mold 1 and lower mold 2, die cavity 3 is arranged between upper mold 1 and lower mold 2, one side of upper mold and lower mold is shaped on feed inlet 4 docked with extruder, upper mold and The other side of the lower mold is formed with a discharge port 9, and a long glass fiber introduction plate 5 is arranged in the upper mold 1, and a long glass fiber introduction hole 6 is formed in the long glass fiber introduction plate, and a long glass fiber introduction hole 6 is arranged in the long glass fiber introduction hole 6. The long glass fiber 7 is penetrated, and a transmission mechanism is set beside the discharge port 9, and a cutting device is installed on the transmission mechanism. The upper mold 1 and the lower mold 2 described in this plan are provided with heating holes 26, and heating pipes are installed in the heating ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com