A kind of recycling glass fiber reinforced plastic melt granulation extrusion equipment and its extrusion method

A reinforced plastic and melt granulation technology, which is applied in the field of recycled glass fiber reinforced plastic melt granulation and extrusion equipment, can solve the problems of reducing the physical properties of modified plastics, poor plastic performance, and limited application range, etc., to improve the mixing effect , Improve physical properties and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

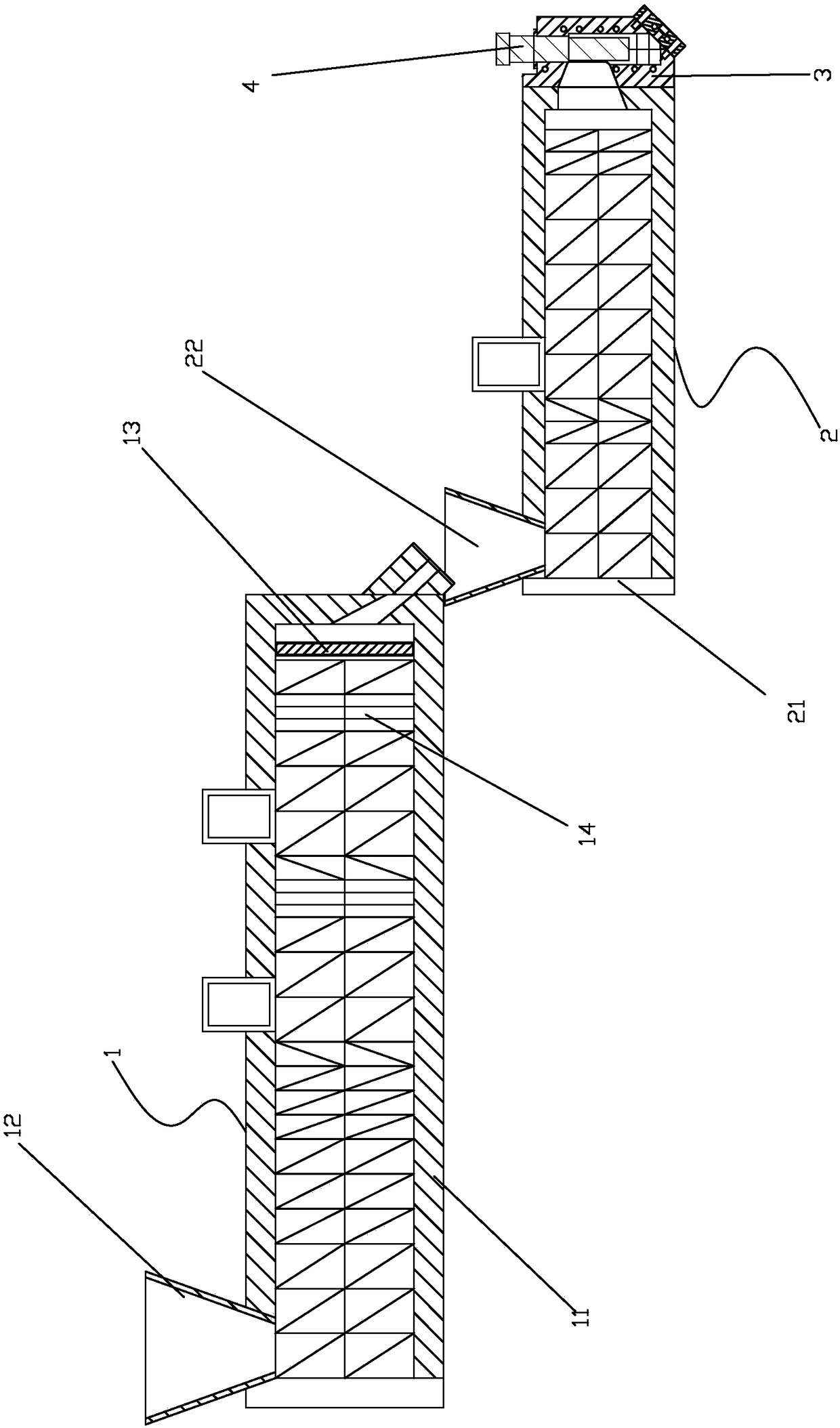

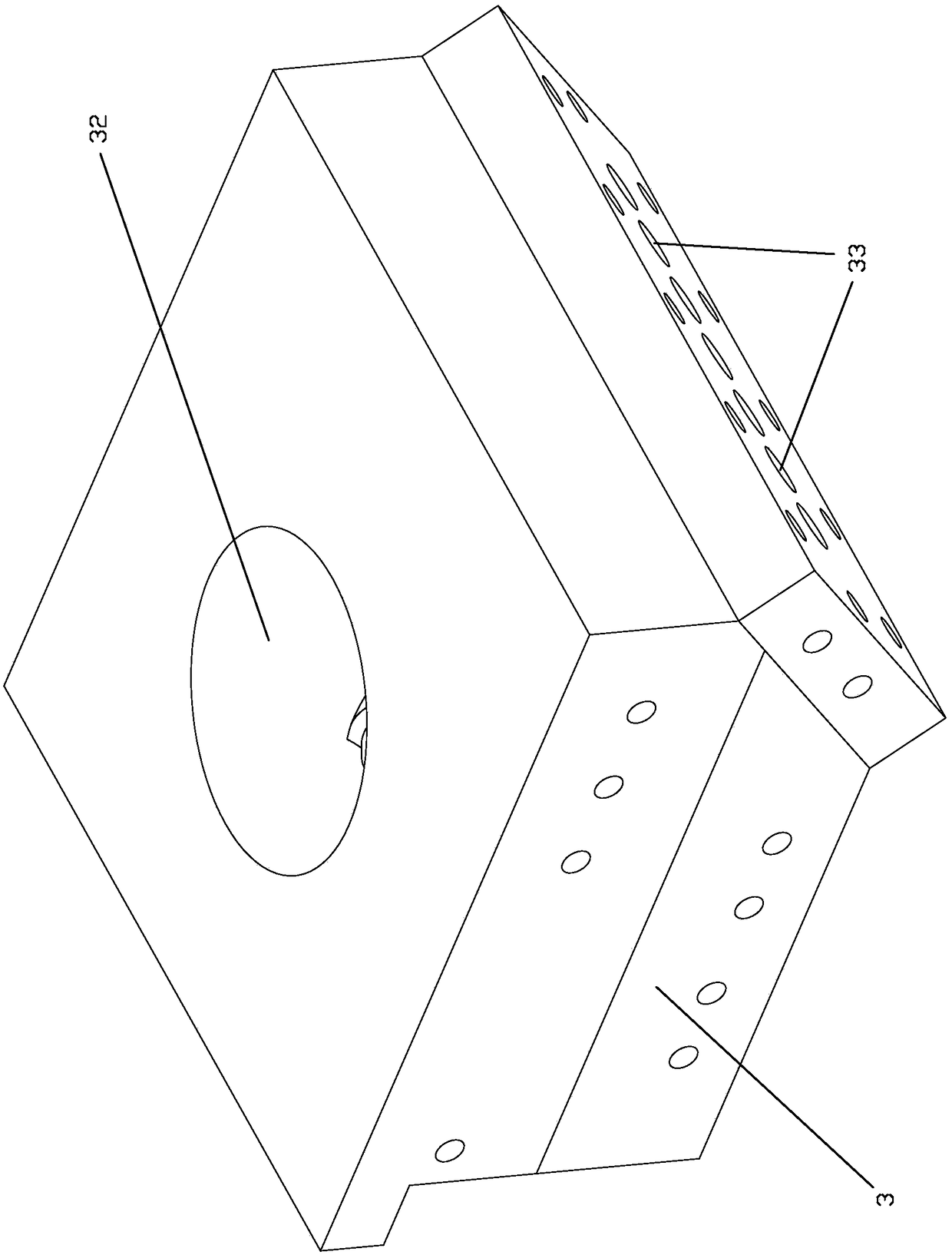

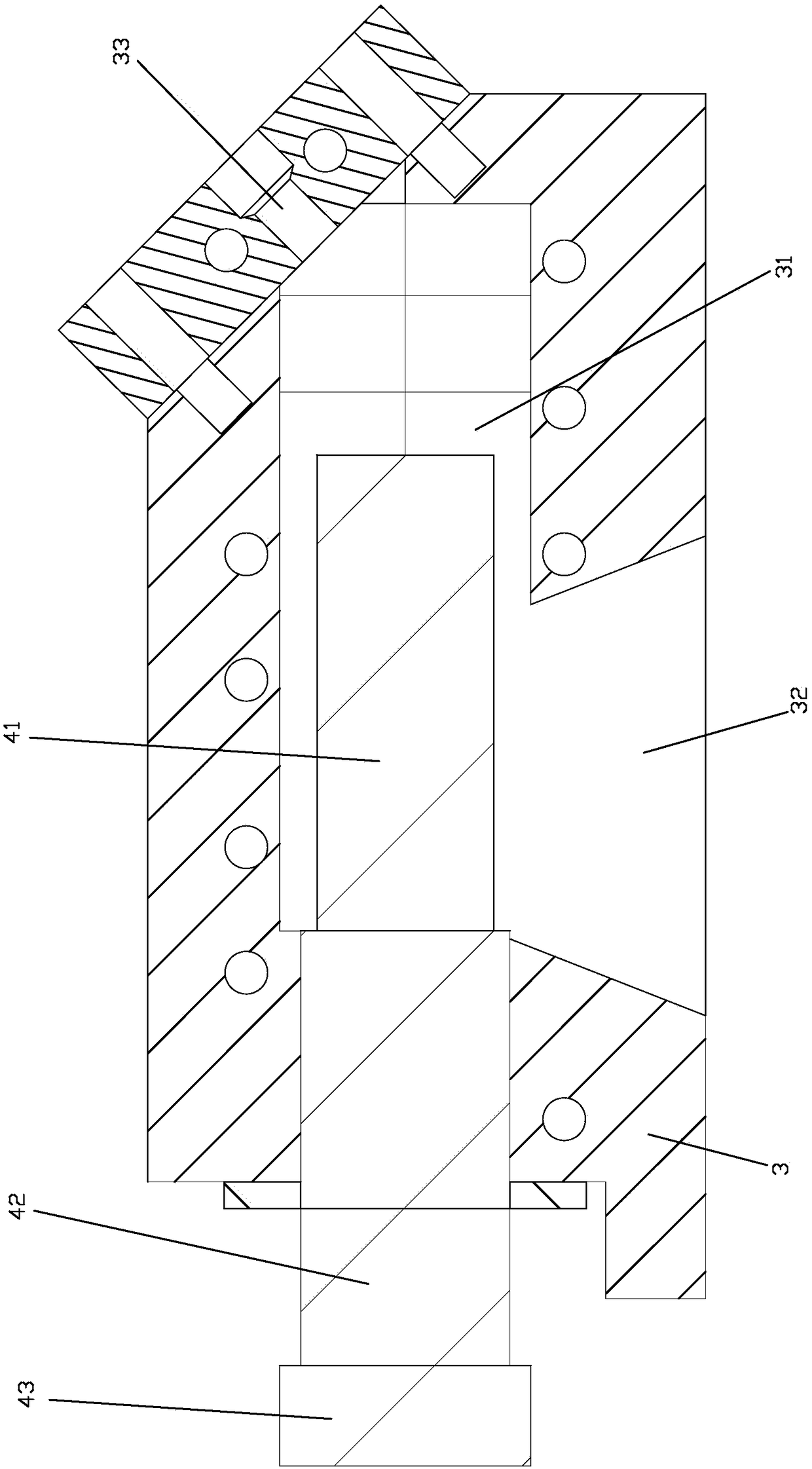

[0030] As shown in the figure, a kind of recycling glass fiber reinforced plastic melt granulation extrusion equipment includes a twin-screw extruder 1 and a single-screw extruder 2 connected in sequence, and the twin-screw extruder 1 includes a heating function A first-stage cylinder body 11, the front portion of the first-stage cylinder body 11 is provided with a first-stage material inlet 12 for feeding, and the rear portion of the first-stage cylinder body 11 is provided with a filter screen 13, and the filter screen 13 is used for To filter the molten polymer, a kneading unit 14 for high-shear polymer is also provided in the first-stage cylinder 11 close to the filter screen (12), and the single-screw extruder 2 includes a The second-stage cylinder 21 with heating function, the front part of the second-stage cylinder 21 is provided with a second-stage material inlet 22, and the second-stage material inlet 22 is used to receive short glass fibers and filter through the filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com