Preparation method of high-strength corrugated raw paper

A corrugated base paper, high-strength technology, applied in the field of papermaking, can solve the problems of immature production technology, inability to provide low shrinkage and paper strength products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

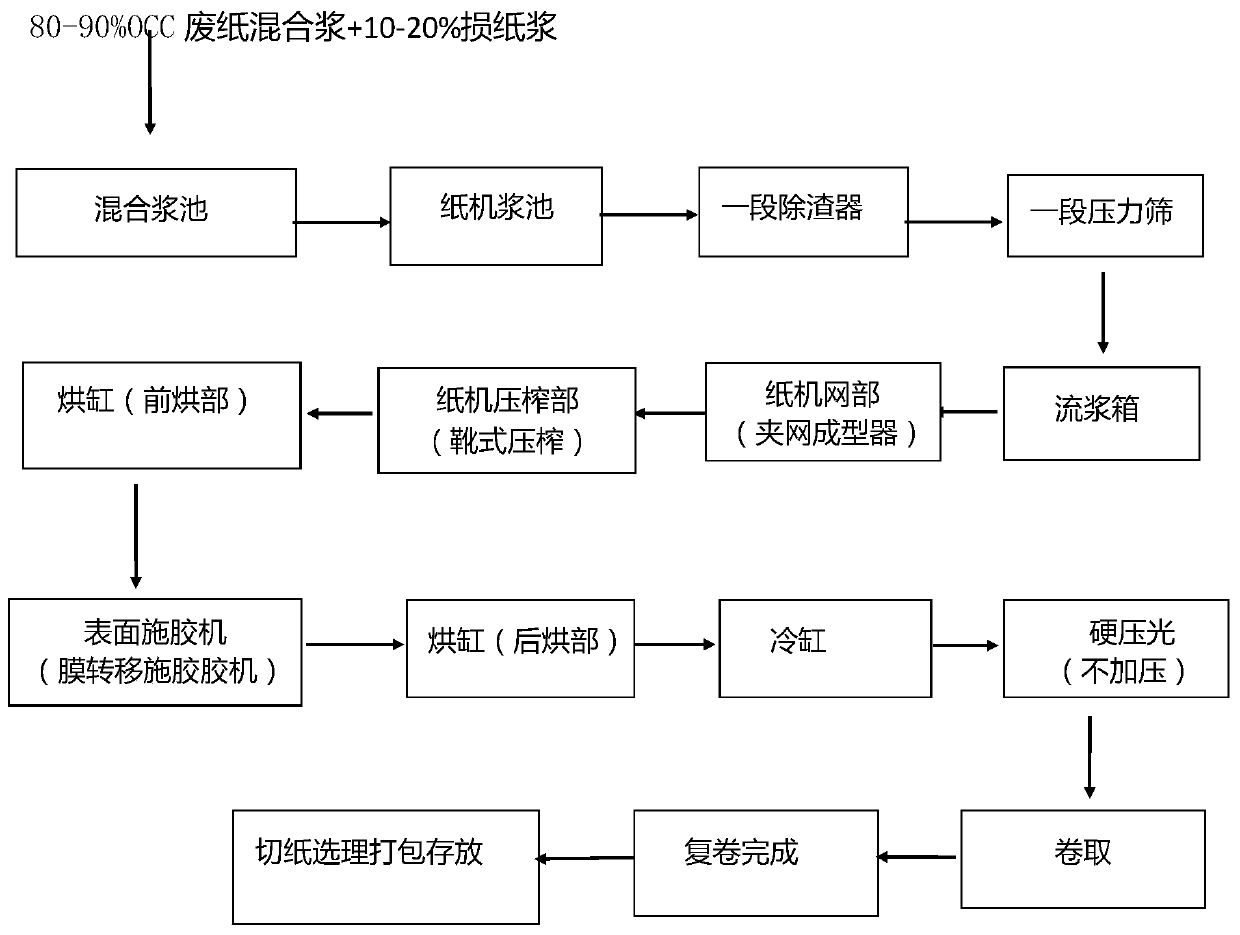

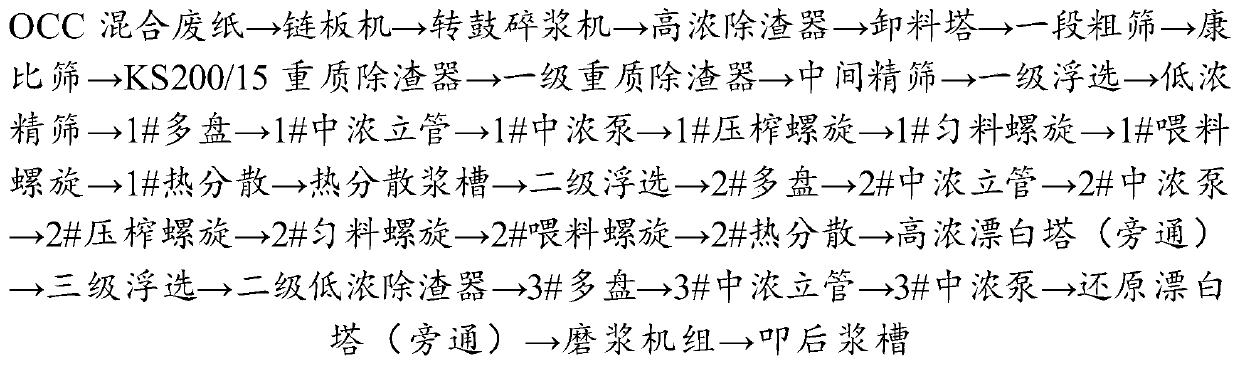

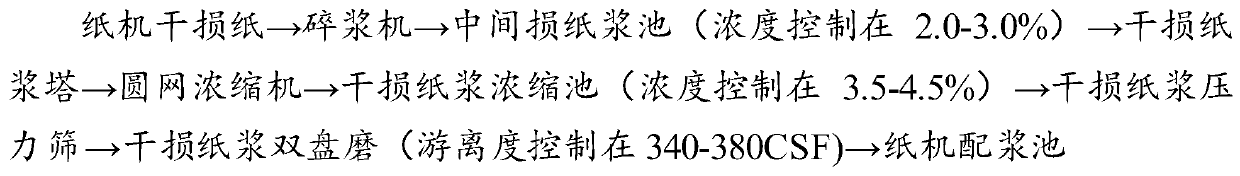

[0031] The invention provides a method for preparing high-strength corrugated base paper, comprising: S1) mixing 30-50 parts by weight of national waste paper, 10-30 parts by weight of Japanese OCC waste paper, and 40-60 parts by weight of European waste OCC and / or British OCC waste paper mixed pulping to obtain OCC waste paper mixed pulp; the national waste paper is grade A and / or B; S2) mixing the OCC waste paper mixed pulp with broke pulp, After slag removal, papermaking and sizing are carried out to obtain high-strength corrugated base paper; the mass ratio of the mixed OCC waste paper to broke pulp is (80-90): (10-20).

[0032] see figure 1 , figure 1 It is a schematic diagram of the preparation process of the high-strength corrugated base paper provided by the present invention.

[0033] Mixing 30-50 parts by weight of national waste paper, 10-30 parts by weight of Japanese OCC waste paper and 40-60 parts by weight of European OCC waste and / or British OCC waste paper...

Embodiment 1

[0062] 50 parts by weight of national waste paper, 10 parts by weight of Japanese OCC waste paper and 40 parts by weight of European waste OCC and / or British OCC waste paper are mixed in a drum pulper for disintegration to obtain pulp, pulp The mass concentration of the material is 3.5%.

[0063] The slurry is subjected to impurity removal by a high-concentration slag remover, and the slurry inlet concentration of the high-concentration slag remover is 3.5%; the slurry inlet pressure is 3.8bar; the inlet slurry flow rate is 10400L / min; the temperature of the slurry is 60°C ; The pH value of the slurry is 8; the pressure difference between the inlet and outlet of the high-concentration slag remover is 1.2bar;2 The removal rate of impurities and dust in the size range is 45%. Then, after a coarse sieve and a combi sieve, the KS200 / 15 heavy slag remover and the first-stage heavy slag remover (the first-stage heavy slag remover The slurry inlet concentration in the device is 1.5%;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com