Preparation method of flexible sensor based on carbon nanometer paper

A carbon nano-paper and sensor technology, applied in the field of sensors, can solve problems such as poor tensile properties, and achieve the effects of improving thickness and uniformity, reducing poor contact and reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with embodiment.

[0037] 1. Adopt the method of invention patent ZL2012104391772 (preparation method of temperature sensor based on carbon nanotube three-dimensional network film) to prepare carbon nanotube three-dimensional network film, which is the carbon nanopaper in the present invention;

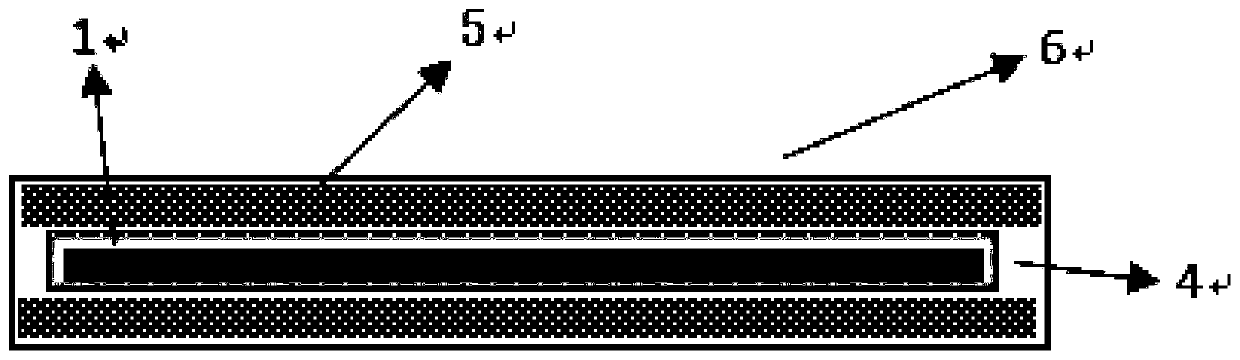

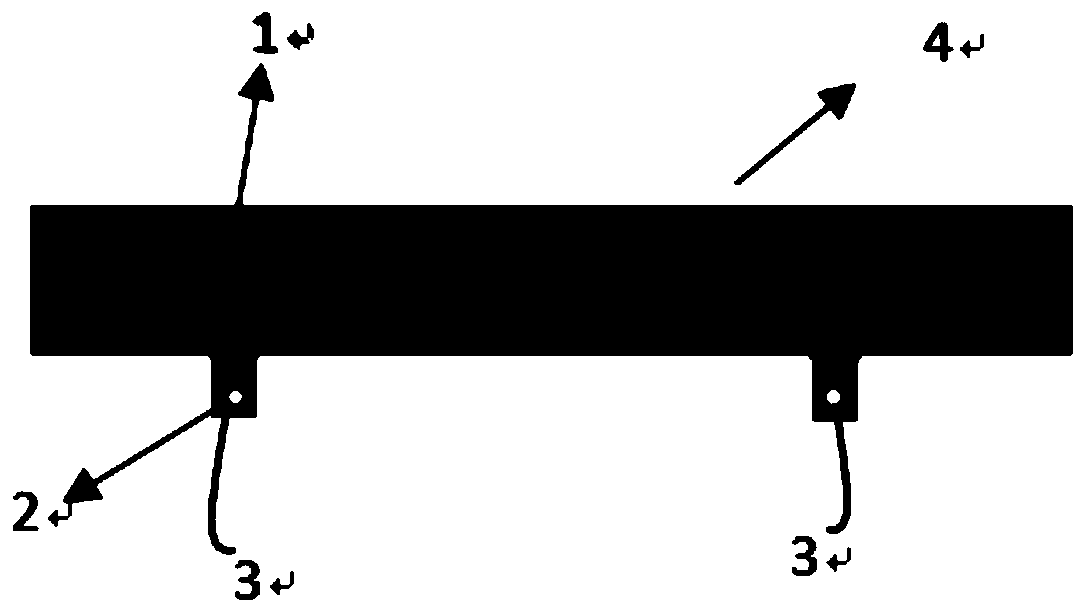

[0038] 2. Schematic diagram of the forming process of the flexible sensor based on carbon nanopaper. figure 1 As shown, the structural schematic diagram of the prepared flexible sensor based on carbon nanopaper is shown in figure 2 As shown, cut the carbon nanopaper 1 according to the size of the mold, and cut the carbon nanopaper 1 into a convex shape at the position where the wire is to be connected to form a connection joint, which is convenient for the wire 3 to be wound and fixed, and put the carbon nanopaper 1 on the glass slide and fixed, using the heating type thermosetting conductive silve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com