Multifunctional thin film for energy storage device and preparation method thereof

A multifunctional, device technology, applied in electrical components, structural parts, battery pack components, etc., can solve the problems of poor electrolyte wettability, poor mechanical properties, insufficient porosity, etc., to avoid stacking or agglomeration, good magnification and The effect of cycle performance, good tensile strength and puncture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A method for preparing a multifunctional thin film for an energy storage device, comprising the steps of:

[0031] S1. Disperse the graphene-based material, the metal-organic framework material or the precursor of the metal-organic framework material in the solvent respectively to obtain the graphene-based material dispersion liquid, the metal-organic framework material dispersion liquid or the metal-organic framework material respectively The precursor dispersion of the material;

[0032] S2, mixing the graphene-based material dispersion obtained in S1 with the metal-organic framework material dispersion or the precursor dispersion of the metal-organic framework material to obtain a mixed system;

[0033] S3. Transfer the mixed system prepared in S2 to a flat substrate;

[0034] S4, removing the solvent to obtain a multifunctional thin film for energy storage devices.

[0035] The graphene-based material described in S1 is single-layer graphene oxide, few-layer graphen...

Embodiment 1

[0040] Weigh 20mg of single-layer graphene oxide, add distilled water and ultrasonically disperse for 1h to make a 2mg / ml solution, and obtain the graphene-based material as solution A; weigh 1.8g of 2-methylimidazole, dissolve it in 30ml of water, and this is solution B ; Weigh 1.2g of zinc nitrate and dissolve it in 20ml of water with stirring, this is solution C. Add solution B to solution A, first stir for 30 minutes, then sonicate for 30 minutes, finally add solution C, and continue stirring for 2 hours. The above mixed solution was filtered to remove the solvent, and the obtained filter membrane was vacuum-dried for 3 hours to finally obtain a composite film material with a thickness of 20 μm.

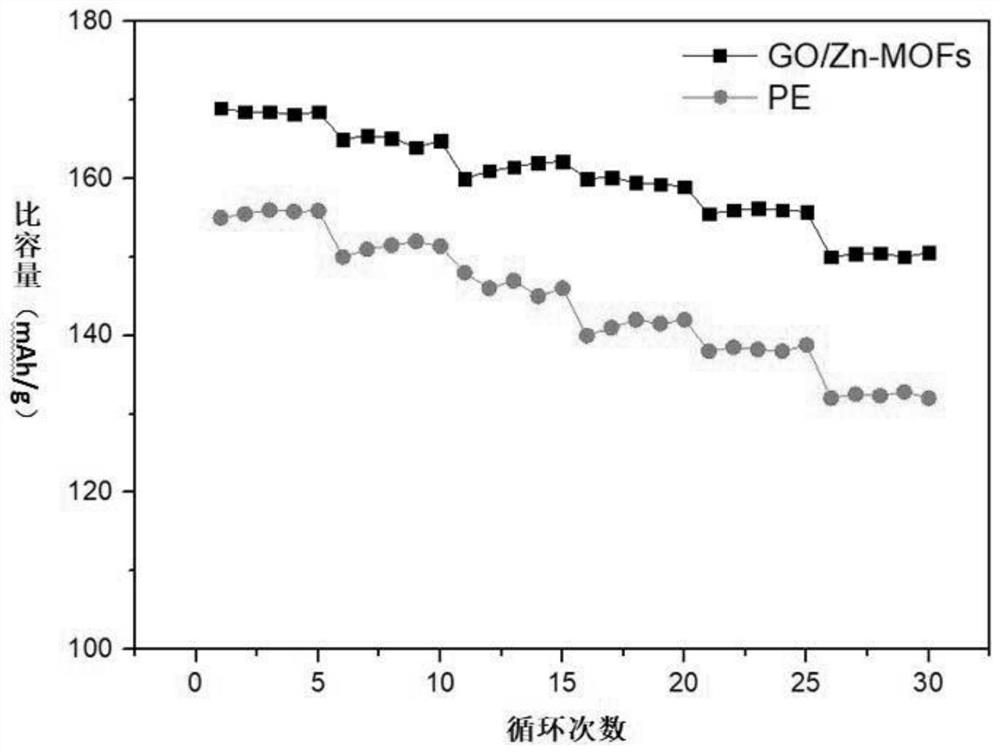

[0041] Using this thin film material as a separator (GO / Zn-MOFs), using commercial lithium iron phosphate as anode material, and lithium sheet as anode and counter electrode, a lithium-ion battery was assembled to evaluate its electrochemical performance, and compared with commer...

Embodiment 2

[0043] Weigh 100 mg of graphene oxide, modify the surface of graphene oxide with p-aminobenzoic acid by diazotization reaction, obtain the graphene oxide modified with benzoic acid, and disperse it into 50ml N, N-dimethylformamide by ultrasonic to obtain A solution of 2 mg / ml is solution A; 2 g of biphenyl dicarboxylic acid and copper nitrate 2.5 are stirred and dissolved in 50 ml of N,N-dimethylformamide, which is solution B. Add solution B to solution A, first stir for 20 min, then sonicate for 1 h, and finally stir for 4 h. The above mixed solution was scraped onto a flat substrate, heated at 150° C. for 5 hours, and the solvent was removed to obtain a composite film material with a thickness of 25 μm.

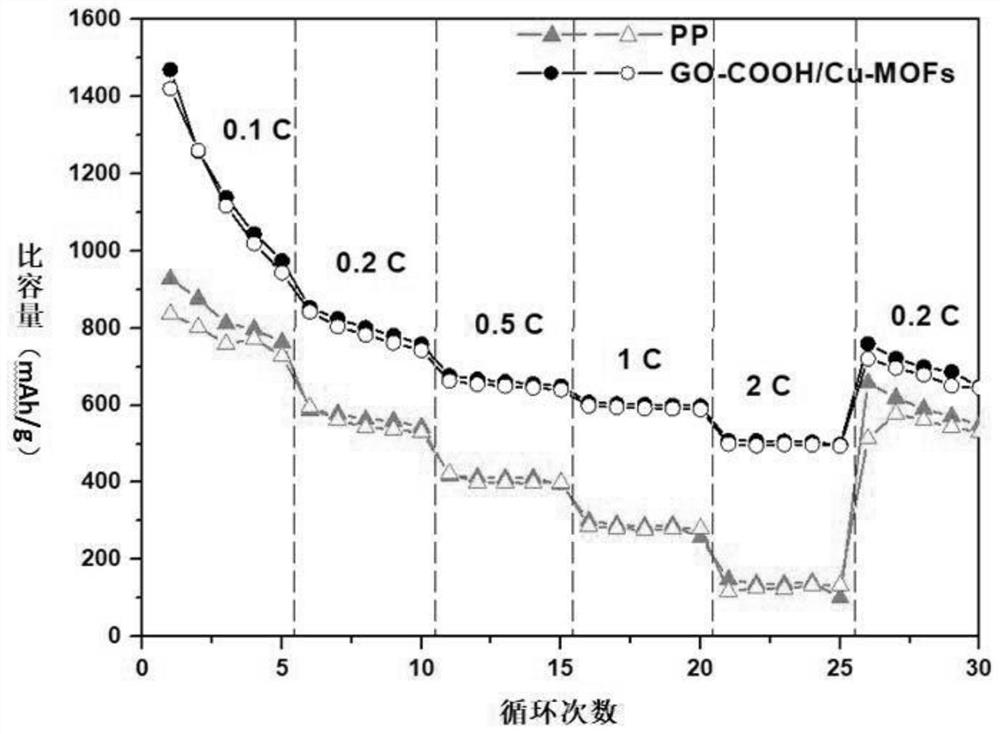

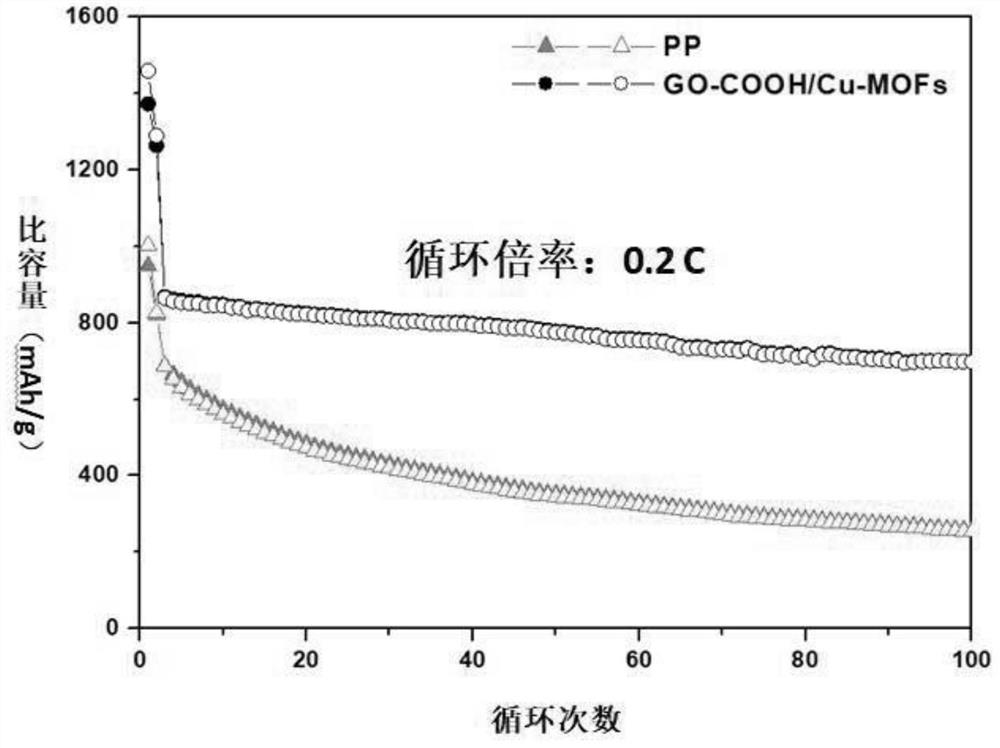

[0044] Using this thin film material as a separator (GO-COOH / Cu-MOFs), using sulfur / carbon as the positive electrode material, and lithium sheets as the negative and counter electrodes, a lithium-sulfur battery was assembled to evaluate its electrochemical performance, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com