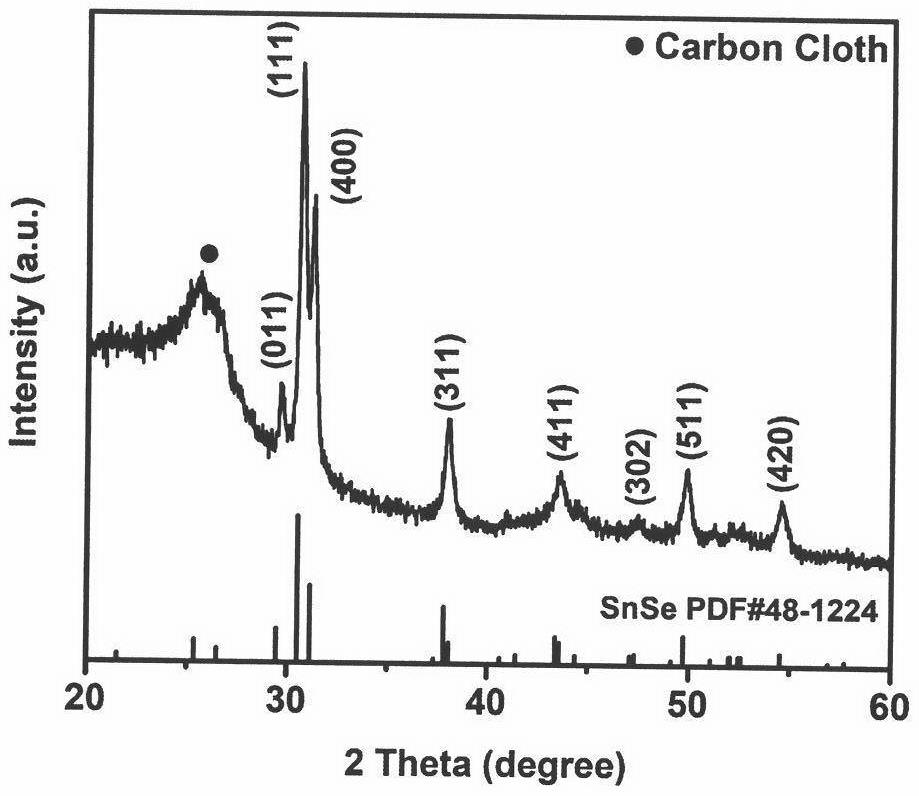

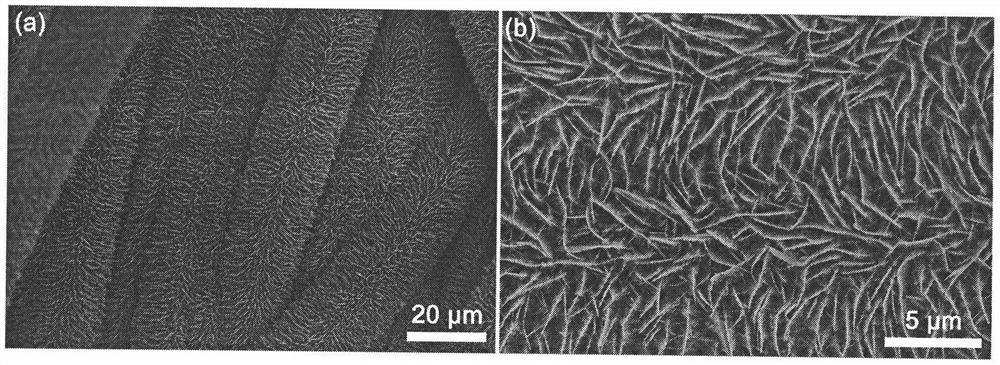

Tin selenide nanosheet array/carbon cloth composite negative electrode material structure for sodium ion battery

A sodium-ion battery and nanosheet array technology, which is applied to battery electrodes, structural parts, circuits, etc., can solve problems such as slowness, achieve the effects of avoiding agglomeration, simple negative electrode structure, and improving specific capacity and cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

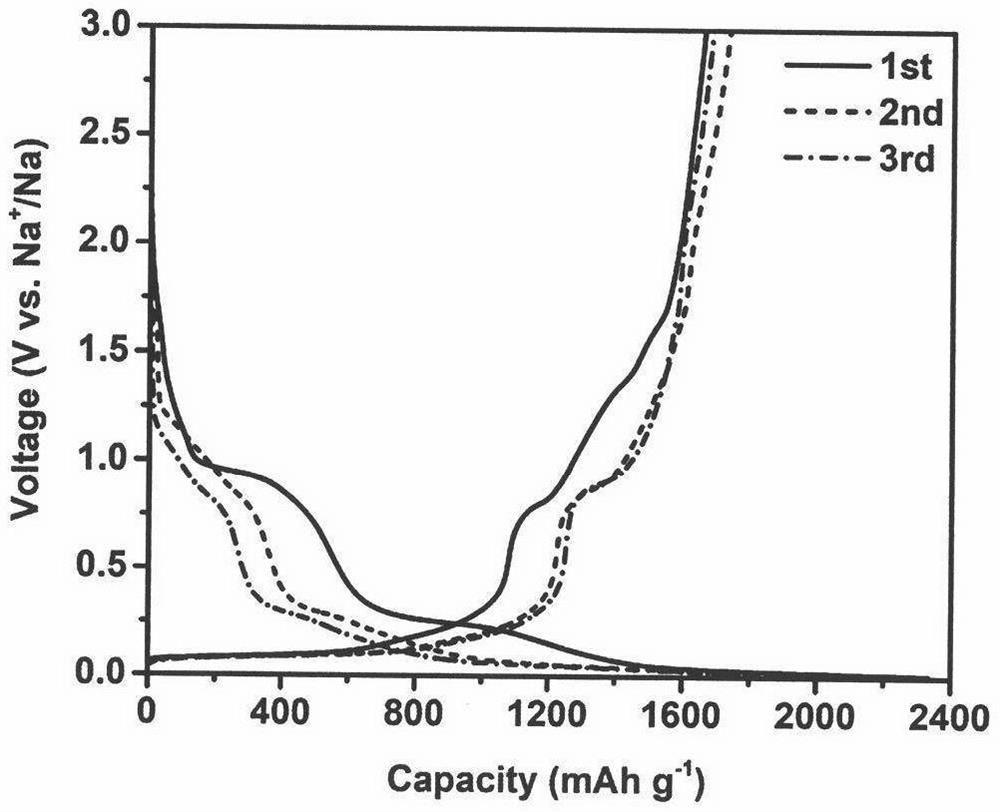

Embodiment 1

[0022] First, cut the carbon cloth into a size of 0.9cm×0.9cm, then wash the carbon cloth with acetone, anhydrous ethanol and deionized water successively, put it in a drying oven to dry, take out the dried carbon cloth, and weigh it with a balance The mass of the carbon cloth was 8.21 mg, and then the vacuum thermal evaporation method was used in a vacuum degree of 5 × 10. -4 The tin selenide powder raw material was heated to 450 °C under Pa and kept for 90 min to prepare a tin selenide array nanosheet array on the carbon cloth. After taking out the sample, the weight was weighed again to 9.57 mg, and the weight of the carbon cloth was subtracted from this weight. Therefore, the mass of the active material was calculated to be 1.36 mg, and then the carbon cloth loaded with the tin selenide nanosheet array was used as the negative electrode of the sodium ion battery, and the positive electrode was the sodium sheet, which was assembled into a button battery for electrochemical p...

Embodiment 2

[0027] First, cut the carbon cloth into a size of 0.9cm×0.8cm, then wash the carbon cloth with acetone, anhydrous ethanol and deionized water successively, put it in a drying oven to dry, take out the dried carbon cloth, and weigh it with a balance The mass of the carbon cloth was 9.72 mg, and then the vacuum thermal evaporation method was used in a vacuum of 5 × 10 -5 The tin selenide powder raw material was heated to 450 °C under Pa and kept for 90 min to prepare a tin selenide array nanosheet array on the carbon cloth. After taking out the sample, the weight was weighed again to 10.97 mg, and the weight of the carbon cloth was subtracted from this weight. Therefore, the mass of the active material was calculated to be 1.25 mg, and then the carbon cloth loaded with the tin selenide nanosheet array was used as the negative electrode of the sodium ion battery, and the positive electrode was the sodium sheet, which was assembled into a button battery for electrochemical performa...

Embodiment 3

[0030] First cut the carbon cloth into a size of 0.8cm×0.8cm, then wash the carbon cloth with acetone, anhydrous ethanol and deionized water successively, put it in a drying box to dry, take out the dried carbon cloth, and weigh it with a balance The mass of the carbon cloth is 8.21mg, and the vacuum degree is 5×10 by the vacuum thermal evaporation method. -5 The tin selenide powder raw material was heated to 450 °C under Pa and kept for 90 mm, and the tin selenide array nanosheet array was prepared on the carbon cloth. After taking out the sample, the weight was weighed again to 9.91 mg, and the weight of the carbon cloth was subtracted from this weight. Therefore, the mass of the active material was calculated to be 1.70 mg, and then the carbon cloth loaded with the tin selenide nanosheet array was used as the negative electrode of the sodium ion battery, and the positive electrode was the sodium sheet, which was assembled into a button battery for electrochemical performance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com