Cement production method

A production method and cement technology, which is applied in the field of cement manufacturing, can solve problems such as damage to the health of operators, reduced bagging efficiency, and blockage of the discharge port, so as to improve the sealing effect, improve the bagging efficiency, and avoid overflow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in a variety of different ways defined and covered by the claims.

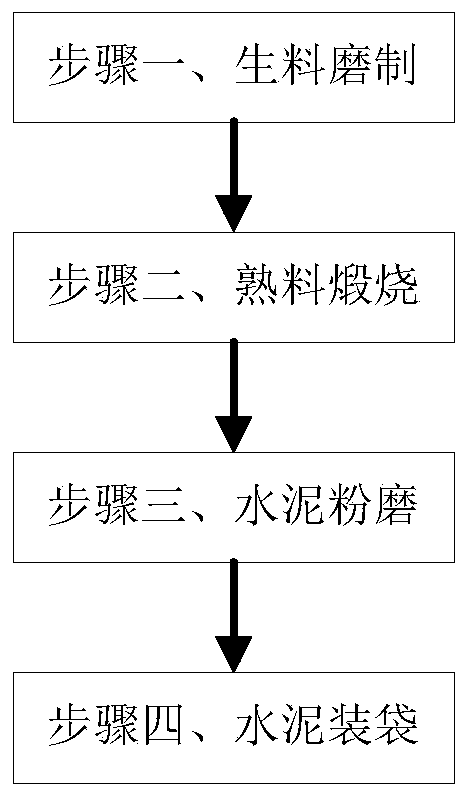

[0039] Such as figure 1 As shown, this embodiment provides a cement production method, including the following steps:

[0040] Step 1. Raw meal grinding: crush and grind limestone and clay and then homogenize;

[0041] Step 2. Clinker calcination: send the homogenized raw meal particles into the preheater and rotary kiln for calcination and curing;

[0042] Step 3. Cement grinding: Grind the calcined clinker to a suitable particle size to form a certain particle size;

[0043] Step 4. Cement bagging: bagging and sealing the ground powdered cement;

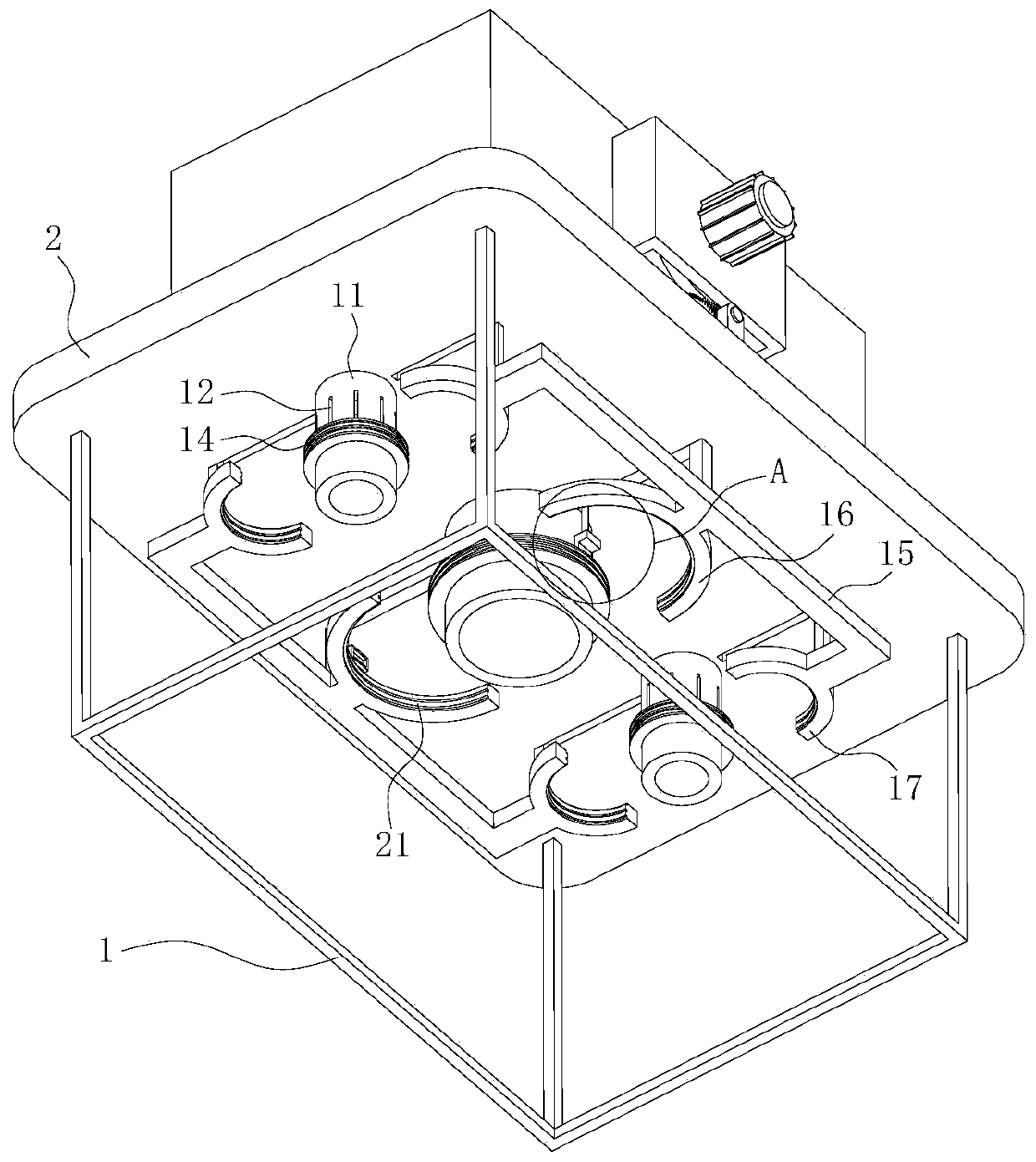

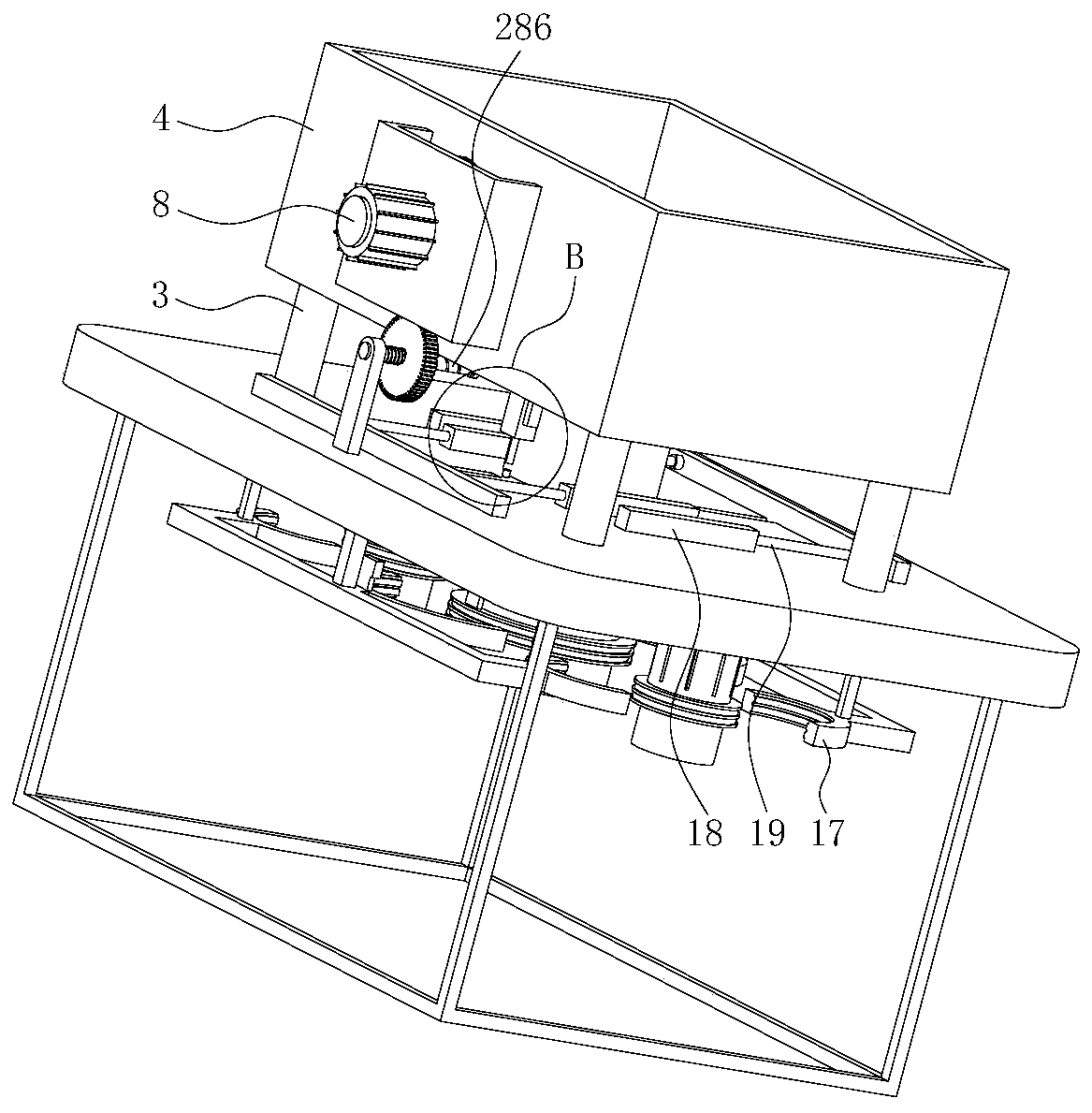

[0044] Among them, the cement bagging process described in step 4 adopts a method such as Figure 2 to Figure 10 The cement bagging machine shown is coordinated. The cement bagging machine includes a suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com