Formula and preparation method of carbon nanotube high-efficiency anticorrosive paint

A technology of carbon nanotubes and anti-corrosion coatings, applied in the direction of anti-corrosion coatings, fire-proof coatings, coatings, etc., can solve the problems of unfavorable storage, easy agglomeration, poor heat resistance, etc., to improve the use performance, improve the use effect, improve The effect of heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

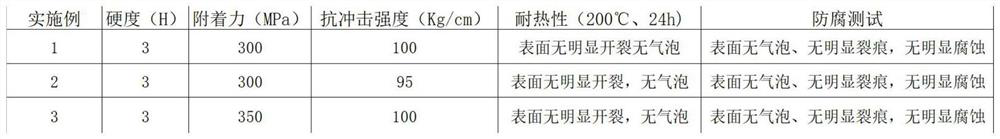

Embodiment 1

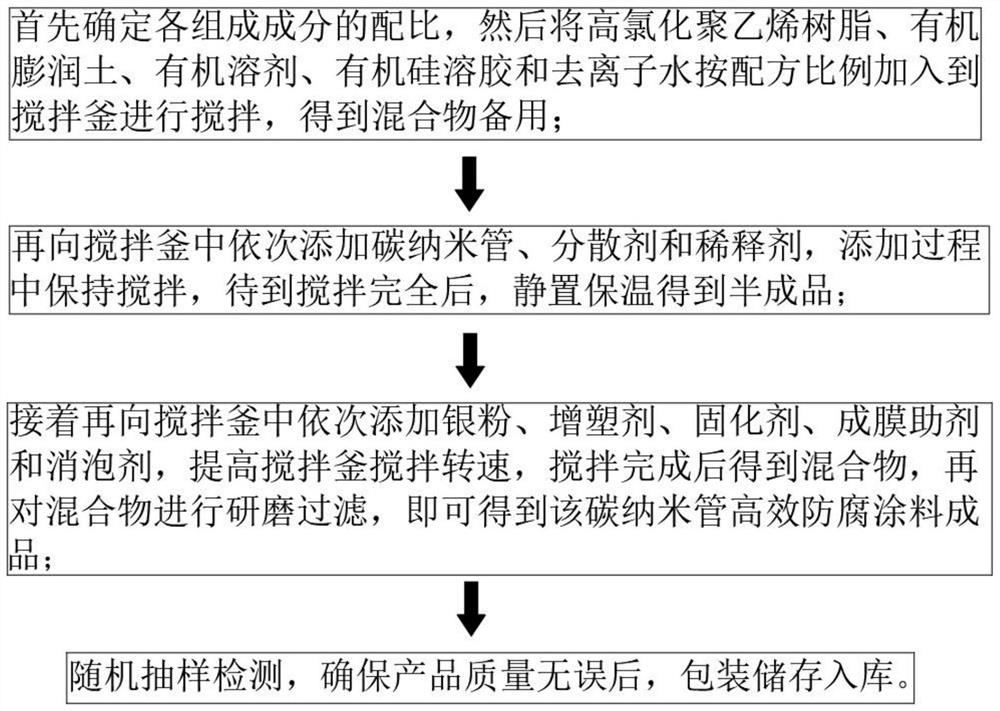

[0028] see Figure 1-2 , the present invention provides a technical solution: a carbon nanotube high-efficiency anti-corrosion coating formula, its raw materials are as follows by proportion: high chlorinated polyethylene resin 44%, organic bentonite 15%, carbon nanotube 4%, organic solvent 6%, 8% silicone sol, 3% defoamer, 5% dispersant, 2% curing agent, 1% film-forming aid, 2% diluent, 3% silver powder, 3% plasticizer and 4% deionized water.

[0029] The material of the organic solvent includes but not limited to styrene, perchlorethylene, trichloroethylene, ethylene glycol ether and triethanolamine, using styrene, perchlorethylene, trichloroethylene, ethylene glycol ether and triethanolamine as the preparation The organic solvent in the process can greatly improve the compatibility between the components of the coating. The material of the defoamer is polydimethylsiloxane and dimethyl silicone oil or a mixture of two of them. The defoamer Then the defoaming effect in the w...

Embodiment 2

[0039] A carbon nanotube high-efficiency anti-corrosion coating formula, its raw materials are as follows by proportion: high chlorinated polyethylene resin 42%, organic bentonite 15%, carbon nanotube 5%, organic solvent 7%, organosilicon sol 9%, defoamer 3%, dispersant 5%, curing agent 3%, coalescent 1%, diluent 1%, silver powder 2%, plasticizer 3% and deionized water 4%.

[0040] The material of the organic solvent includes but not limited to styrene, perchlorethylene, trichloroethylene, ethylene glycol ether and triethanolamine, using styrene, perchlorethylene, trichloroethylene, ethylene glycol ether and triethanolamine as the preparation The organic solvent in the process can greatly improve the compatibility between the components of the coating. The material of the defoamer is polydimethylsiloxane and dimethyl silicone oil or a mixture of two of them. The defoamer Then the defoaming effect in the whole coating preparation process can be improved.

[0041] The material ...

Embodiment 3

[0050] A carbon nanotube high-efficiency anti-corrosion coating formula, its raw materials are as follows by proportion: high chlorinated polyethylene resin 45%, organic bentonite 15%, carbon nanotube 4%, organic solvent 6%, organosilicon sol 8%, defoamer 3%, dispersant 5%, curing agent 2%, film-forming aid 1%, diluent 1%, silver powder 2%, plasticizer 2% and deionized water 6%.

[0051] The material of the organic solvent includes but not limited to styrene, perchlorethylene, trichloroethylene, ethylene glycol ether and triethanolamine, using styrene, perchlorethylene, trichloroethylene, ethylene glycol ether and triethanolamine as the preparation The organic solvent in the process can greatly improve the compatibility between the components of the coating. The material of the defoamer is polydimethylsiloxane and dimethyl silicone oil or a mixture of two of them. The defoamer Then the defoaming effect in the whole coating preparation process can be improved.

[0052] The mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com