Medium-temperature fast-curing flame-retardant epoxy resin and preparation method thereof

An epoxy resin and rapid curing technology, which is applied in the field of composite materials, can solve the problem that phenolic resin-based flame-retardant composite materials cannot fully meet the requirements of advanced equipment mechanical properties and environmental safety performance, poor mechanical properties and process properties of phenolic resin, and produce A large amount of smoke or even toxic gas and other problems can achieve the effect of reducing product transportation and storage costs, excellent overall performance, and exempting from cold chain transportation

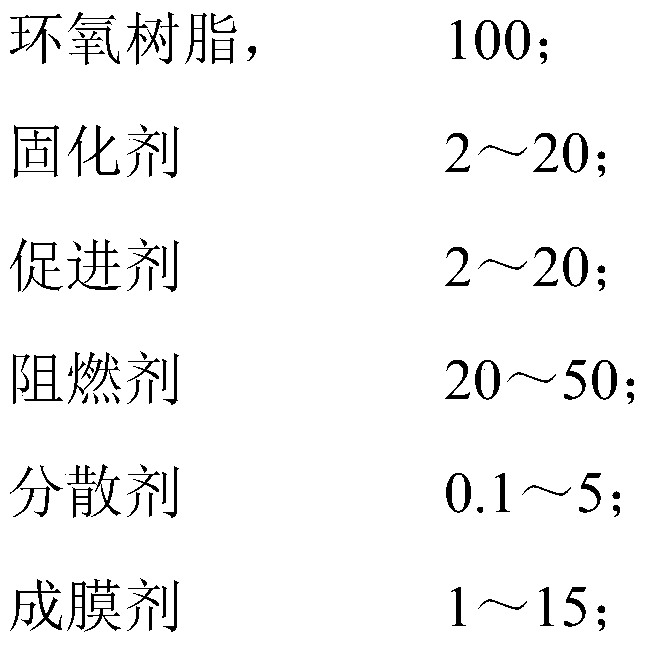

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

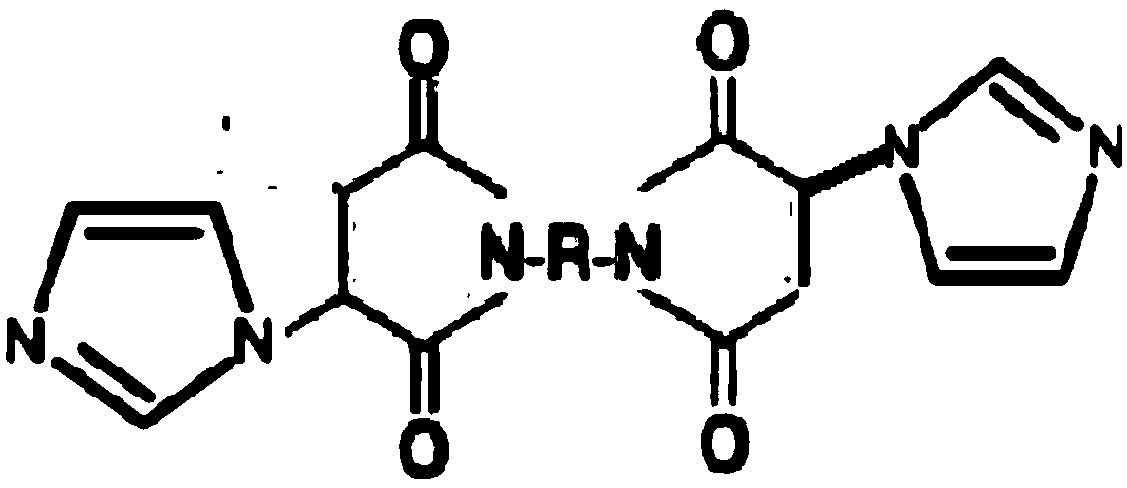

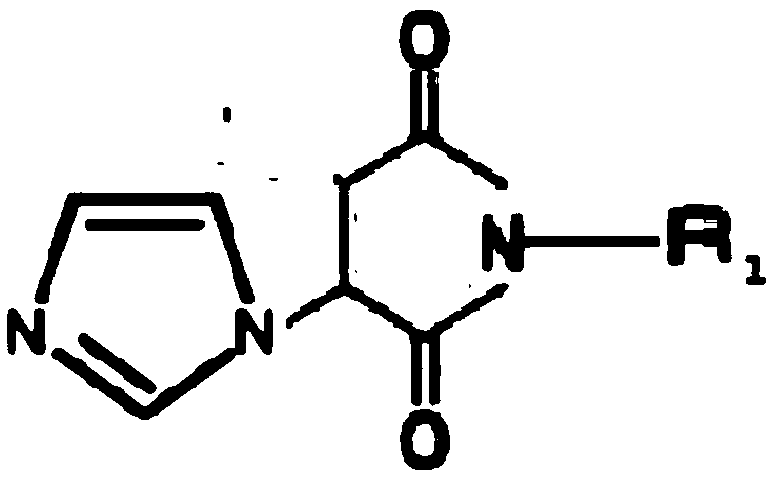

Method used

Image

Examples

Embodiment 1

[0041] The steps of preparing the medium-temperature fast-curing flame-retardant epoxy resin described in the method of the present invention are as follows:

[0042] Add 50 parts of bisphenol A epoxy resin E51, 50 parts of o-cresol type phenolic resin JF45, 5 parts of thermoplastic modified polyether ketone PEKC and 1 part of dispersant HYPER100C in the reactor, heat and stir, and the temperature rises When the system is completely dissolved at 150°C to 160°C, stop heating and stirring, and cool down for later use.

[0043] Transfer the above prepolymer into a planetary disperser or kneader for stirring and heating to 80°C~120°C, then add 20 parts of melamine cyanurate (MCA) and 20 parts of ammonium polyphosphate (APP), and stir for 10 minutes Finally, add 4 parts of dicyandiamide curing agent and 4 parts of modified accelerator NK-MD in proportion, control the temperature of the material system not to exceed 70°C, continue stirring and mixing for 5-20 minutes, and discharge ...

Embodiment 2

[0048] The steps of preparing the medium-temperature fast-curing flame-retardant epoxy resin described in the method of the present invention are as follows:

[0049]10 parts of bisphenol F epoxy resin 630, 40 parts of DOPO type liquid phosphorus epoxy resin SENP-6630, 30 parts of bisphenol A type novolac epoxy resin BPANE8200, 30 parts of phenol formaldehyde epoxy resin PXNE2000, 3 parts of Add thermoplastic polyimide ULTEM1000, 3 parts of thermoplastic polyethersulfone (PES), 1 part of dispersant HYPER100C, and 1 part of white carbon black 380, heat and stir in the reaction kettle, and the temperature rises to 150 ° C ~ 160 ° C system After completely dissolving evenly, stop heating and stirring, and cool down for later use.

[0050] Transfer the above prepolymer into a planetary disperser or kneader, stir and heat to 80°C~120°C, then add 10 parts of melamine cyanurate (MCA), 20 parts of ammonium polyphosphate (APP), 2 parts of three Antimony oxide, 10 parts of magnesium hy...

Embodiment 3

[0055] The steps of preparing the medium-temperature fast-curing flame-retardant epoxy resin described in the method of the present invention are as follows:

[0056] 10 parts of N,N-diglycidyl p-aminophenol glycidylamine AFG90, 40 parts of DOPO type liquid phosphorus-containing epoxy resin SENP-6630, 10 parts of DOPO-HQ type solid phosphorus-containing epoxy resin XEN-0230, 30 parts Bisphenol A type novolac epoxy resin BPANE8200, 30 parts o-cresol type novolac epoxy resin JF45, 2 parts thermoplastic polyphenylene ether SA9000, 3 parts thermoplastic polyether ketone ketone PEKK, 1 part dispersant HYPER100C, 1 part Parts of octaphenyloctasilsesquioxane (POSS) are added and heated and stirred during the reaction, the temperature rises to 150°C to 160°C and the system is completely dissolved and uniform, then the heating and stirring are stopped, and cooled for later use.

[0057] Transfer the above prepolymer into a planetary disperser or kneader, stir and heat to 80°C~120°C, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com