A conductive organic polymer-wrapped phenolic resin-based porous carbon composite

A technology of conductive polymers and phenolic resins, applied in the direction of hybrid capacitor electrodes, etc., can solve the problems of slow polymer monomer polymerization and polymer agglomeration, achieve good specific energy density, simple preparation process, and reduce the effect of transmission routes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

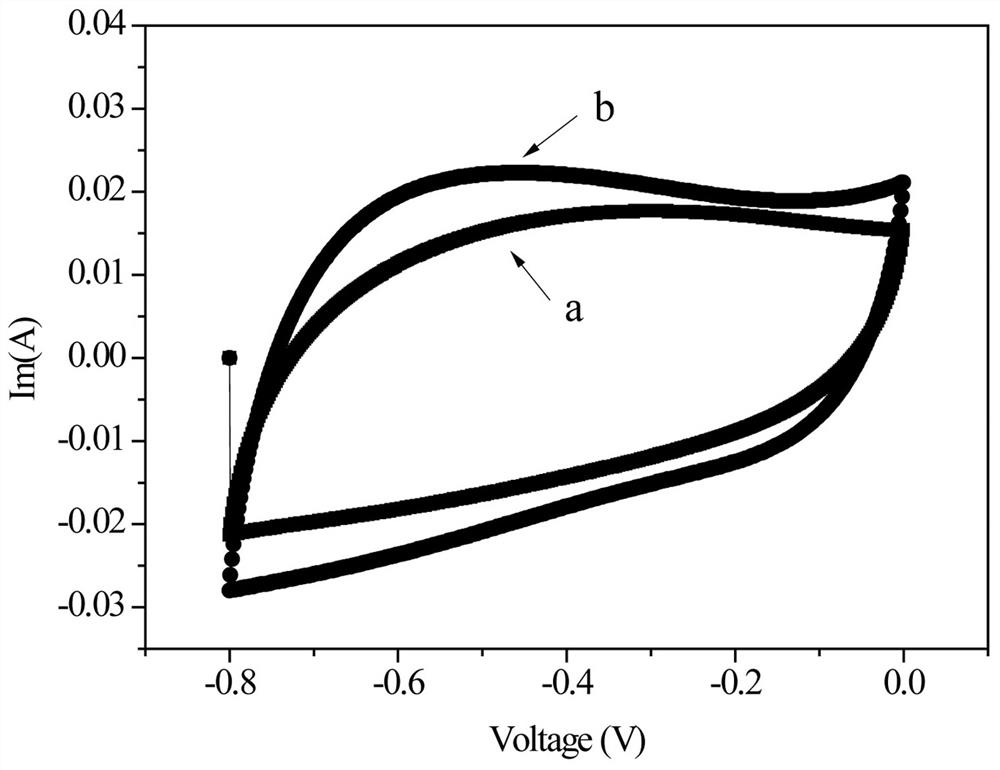

Image

Examples

Embodiment 1

[0042] (1) Preparation of cured phenolic resin: Dissolve 5g of thermoplastic phenolic resin in 300mL of absolute ethanol to dissolve completely, and prepare an absolute ethanol solution with a concentration of phenolic resin of 16.67g / L. 8wt% urotropine to obtain a mixture, the mixture was mechanically stirred at room temperature for 30min, and then the mixture was placed in an oven at 70°C for 2h to complete the pre-curing, then the oven was heated to 150°C, and after curing for 16h , to obtain cured phenolic resin.

[0043] (2) Preparation of phenolic resin-based porous carbon: place the cured phenolic resin obtained in step (1) in a tube furnace in a nitrogen atmosphere, control the heating rate at 8°C / min, and gradually increase the temperature of the tube furnace from room temperature To 900°C, heat-preserve and carbonize for 3 hours to obtain phenolic resin-based porous carbon.

[0044] (3) Preparation of polyaniline-wrapped phenolic resin-based porous carbon composite ...

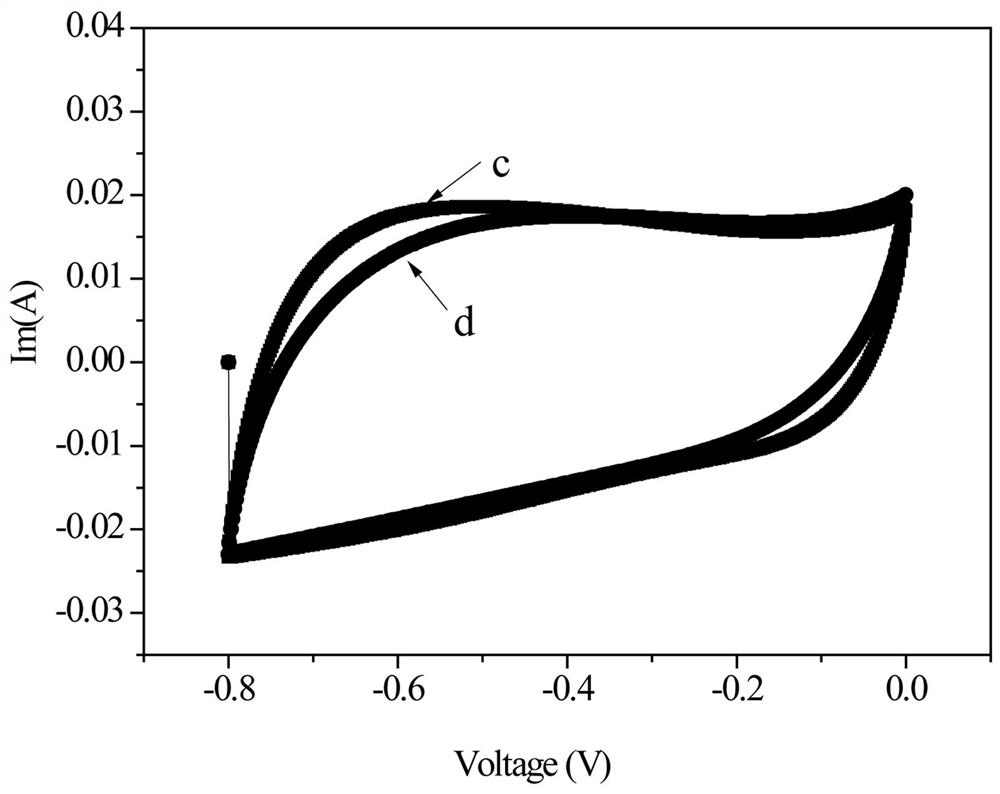

Embodiment 2

[0046] (1) Preparation of cured phenolic resin: Dissolve 4.8g of thermoplastic phenolic resin in 300mL of absolute ethanol to dissolve completely, and prepare an absolute ethanol solution with a concentration of 16g / L of phenolic resin, and add 7wt% urethane The mixture was obtained after rotropine, and the mixture was mechanically stirred at room temperature for 20 minutes, and then the mixture was placed in an oven at 60°C for 1 hour to complete pre-curing. resin.

[0047] (2) Preparation of phenolic resin-based porous carbon: place the cured phenolic resin obtained in step (1) in a tube furnace in a nitrogen atmosphere, control the heating rate at 5°C / min, and gradually increase the temperature of the tube furnace from room temperature To 850°C, heat-preserve and carbonize for 1 hour to obtain phenolic resin-based porous carbon.

[0048] (3) Preparation of polypyrrole-wrapped phenolic resin-based porous carbon composite material: First, add 1 g of the phenolic resin-based ...

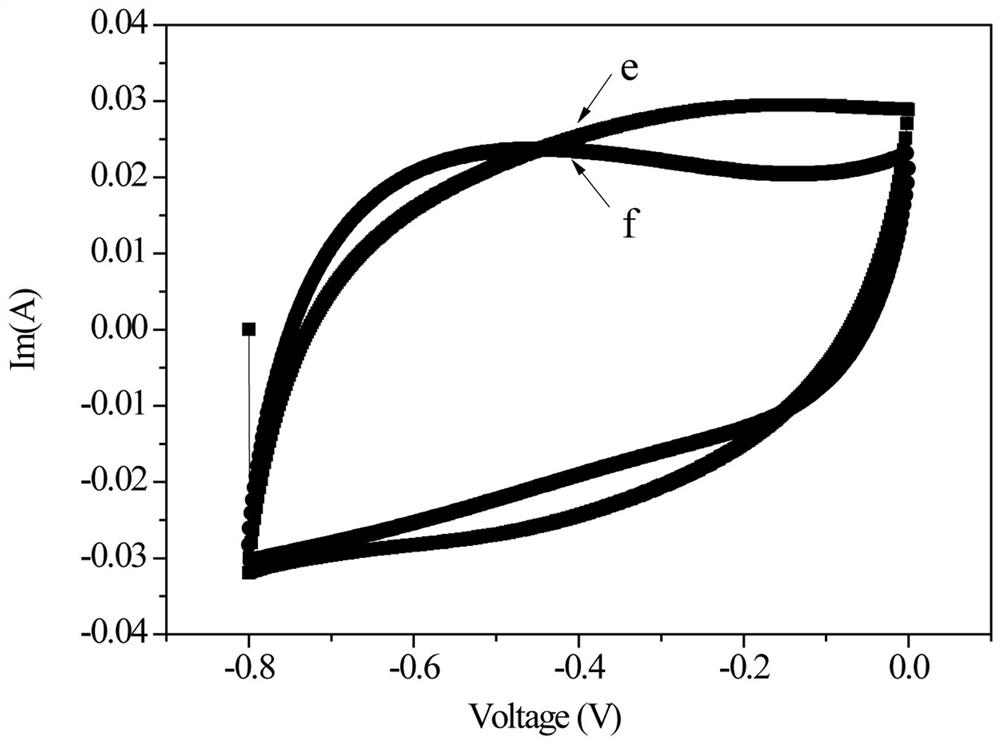

Embodiment 3

[0050] (1) Preparation of cured phenolic resin: Dissolve 5.1g of thermoplastic phenolic resin in 300mL of absolute ethanol to make it completely dissolved, prepare an absolute ethanol solution with a concentration of 17g / L of phenolic resin, add 10wt% urethane The mixture was obtained after rotropine, and the mixture was mechanically stirred at room temperature for 40 minutes, and then the mixture was placed in an oven at 80°C for 3 hours to complete pre-curing. resin.

[0051] (2) Preparation of phenolic resin-based porous carbon: place the cured phenolic resin obtained in step (1) in a tube furnace in a nitrogen atmosphere, control the heating rate at 10°C / min, and gradually increase the temperature of the tube furnace from room temperature To 950°C, heat-preserve and carbonize for 5 hours to obtain phenolic resin-based porous carbon.

[0052] (3) Preparation of polydopamine-coated phenolic resin-based porous carbon composite material: First, add 3 g of the phenolic resin-b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com