High-conductivity flexible touch graphene composite material and preparation method thereof

A technology of flexible touch and composite materials, which is applied in the field of highly conductive flexible touch graphene composite materials and its preparation, can solve the problems of low conductivity, easy agglomeration, and poor ductility of composite materials, so as to optimize the conductive network structure, Satisfies application requirements and enhances conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A method for preparing a highly conductive flexible touch graphene composite material of the present invention is characterized in that the steps are:

[0024] (1) weigh the parts by weight of each component by formula;

[0025] (2) Add carbon nanotubes to the graphene hydrosol, place the mixed system in an ultrasonic instrument for ultrasonic dispersion for 3-4 hours, and obtain a graphene-carbon nanotube composite dispersion, which is then placed in a vacuum drying oven after suction filtration and washing Overnight at 65°C;

[0026] (3) The graphene-carbon nanotube composite dispersion in step (2) is placed in agitating ball milling equipment, and carboxymethylcellulose potassium and zirconium dioxide powder are added while stirring at a speed of 1300-1500r / min , silver powder, and polydimethylsiloxane, after the addition is complete, fully mix for 40 minutes to obtain a mixed system;

[0027] (4) Place the mixing system in a mechanical stirring device, add polyimi...

Embodiment 1

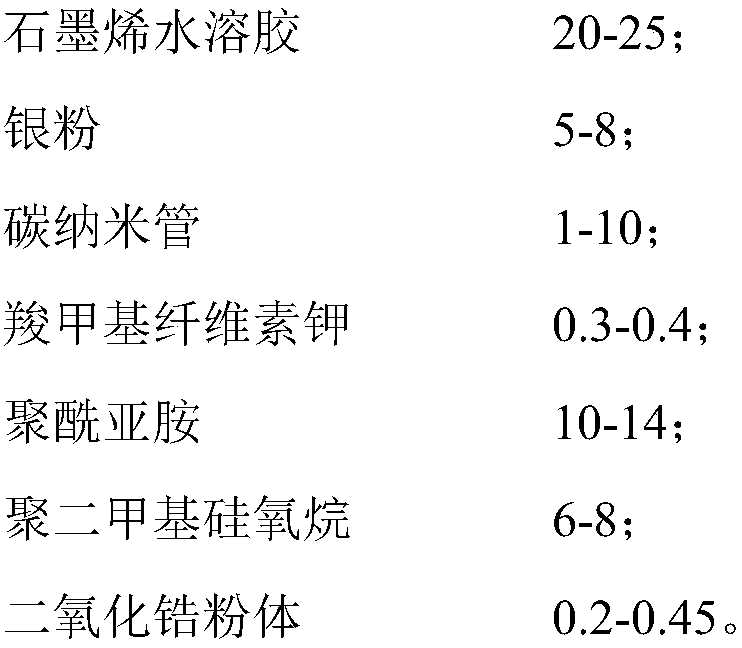

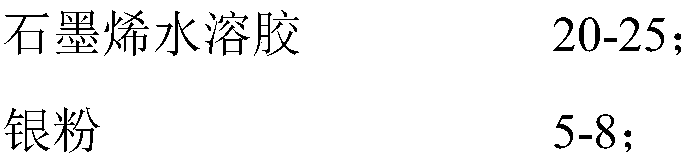

[0030] A kind of highly conductive flexible touch graphene composite material, its parts by weight are composed as follows:

[0031]

[0032]

[0033] The graphene hydrosol is composed of 2 parts of graphene oxide, 2 parts of hydrazine hydrate, 2 parts of concentrated ammonia water and 14 parts of distilled water by mass.

[0034] The particle size of the zirconia powder is 0.1 μm.

[0035] The particle size of the silver powder is 0.1 μm.

[0036] Preparation method: Taking the preparation of a highly conductive flexible touch graphene composite material as an example, the preparation method of a highly conductive flexible touch graphene composite material provided in this embodiment is described as follows:

[0037] (1) Weigh 20 parts of graphene hydrosol, 5 parts of silver powder with a particle size of 0.1 μm, 1 part of carbon nanotube, 0.3 part of carboxymethylcellulose potassium, 10 parts of polyimide, and polydimethylcellulose according to the formula. 6 parts o...

Embodiment 2

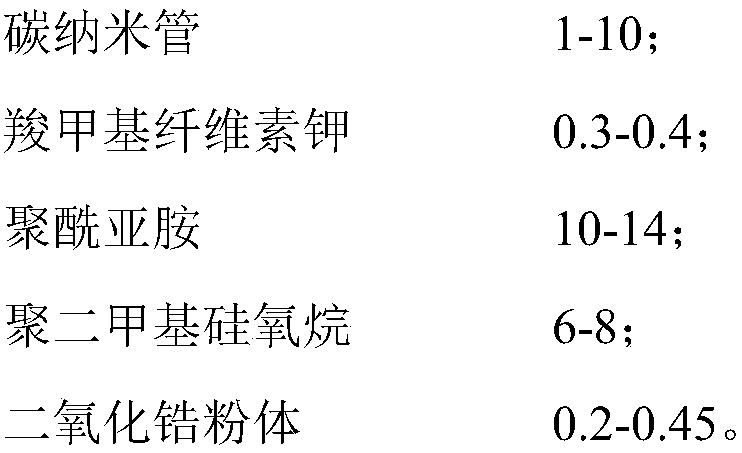

[0043] A kind of highly conductive flexible touch graphene composite material, its parts by weight are composed as follows:

[0044]

[0045]

[0046] The graphene hydrosol is composed of 2.5 parts of graphene oxide, 2.5 parts of hydrazine hydrate, 2.5 parts of concentrated ammonia water and 17.5 parts of distilled water by mass.

[0047] The particle size of the zirconia powder is 0.3 μm.

[0048] The particle size of the silver powder is 0.5 μm.

[0049] Preparation method: Taking the preparation of a highly conductive flexible touch graphene composite material as an example, the preparation method of a highly conductive flexible touch graphene composite material provided in this embodiment is described as follows:

[0050] (1) Weigh 25 parts of graphene hydrosol, 8 parts of silver powder with a particle size of 0.5 μm, 10 parts of carbon nanotubes, 0.4 parts of carboxymethylcellulose potassium, 14 parts of polyimide, and polydimethylcellulose according to the formula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com