Composite material combining PVC (Polyvinyl Chloride) elastomer with super high molecular weight and fluorubber and preparation method thereof

An ultra-high molecular weight, polyvinyl chloride technology, used in insulators, electrical components, etc., can solve the problems of general, large compression set, hardening of materials, etc., and achieve the effects of low brittleness temperature, easy control, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

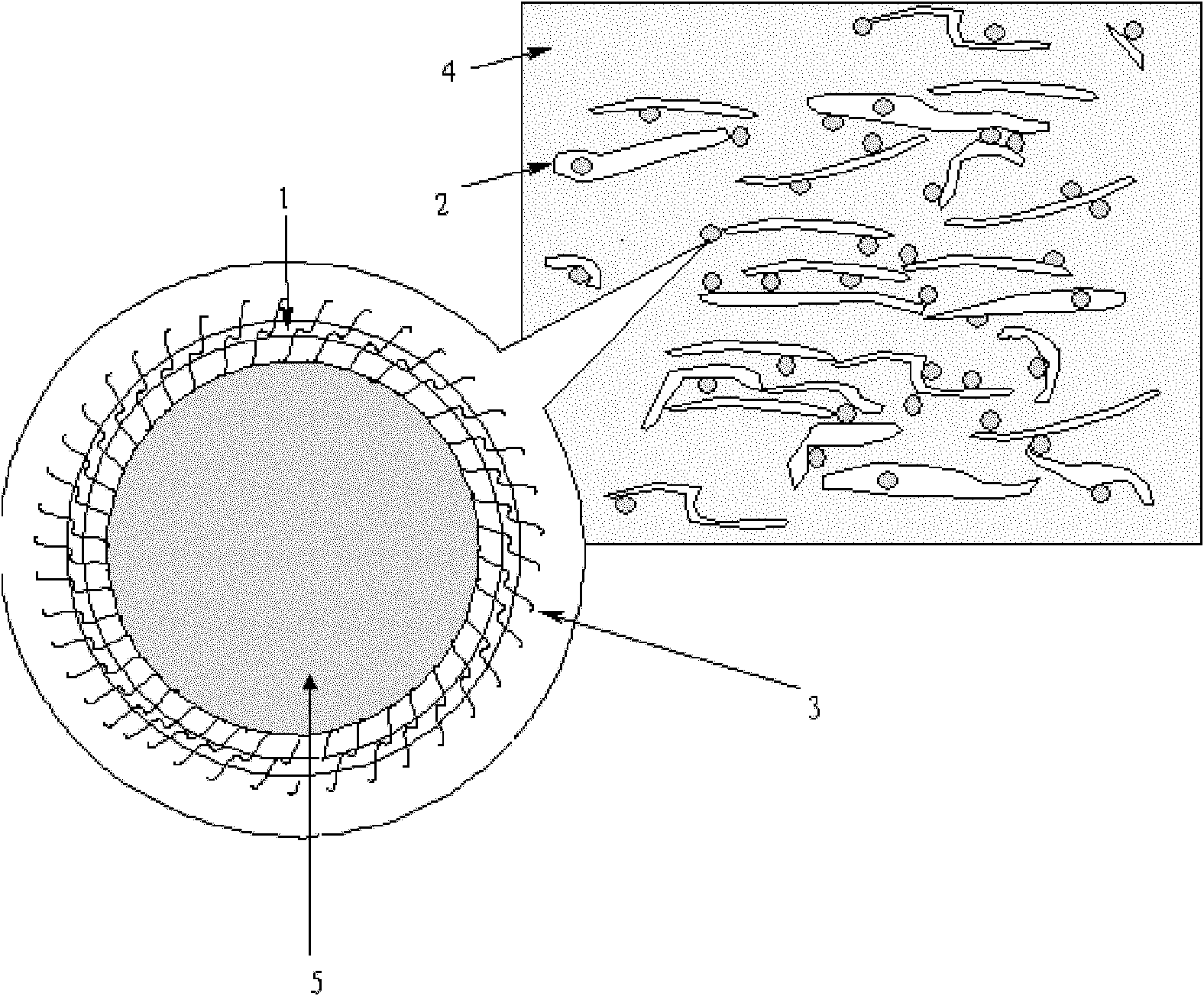

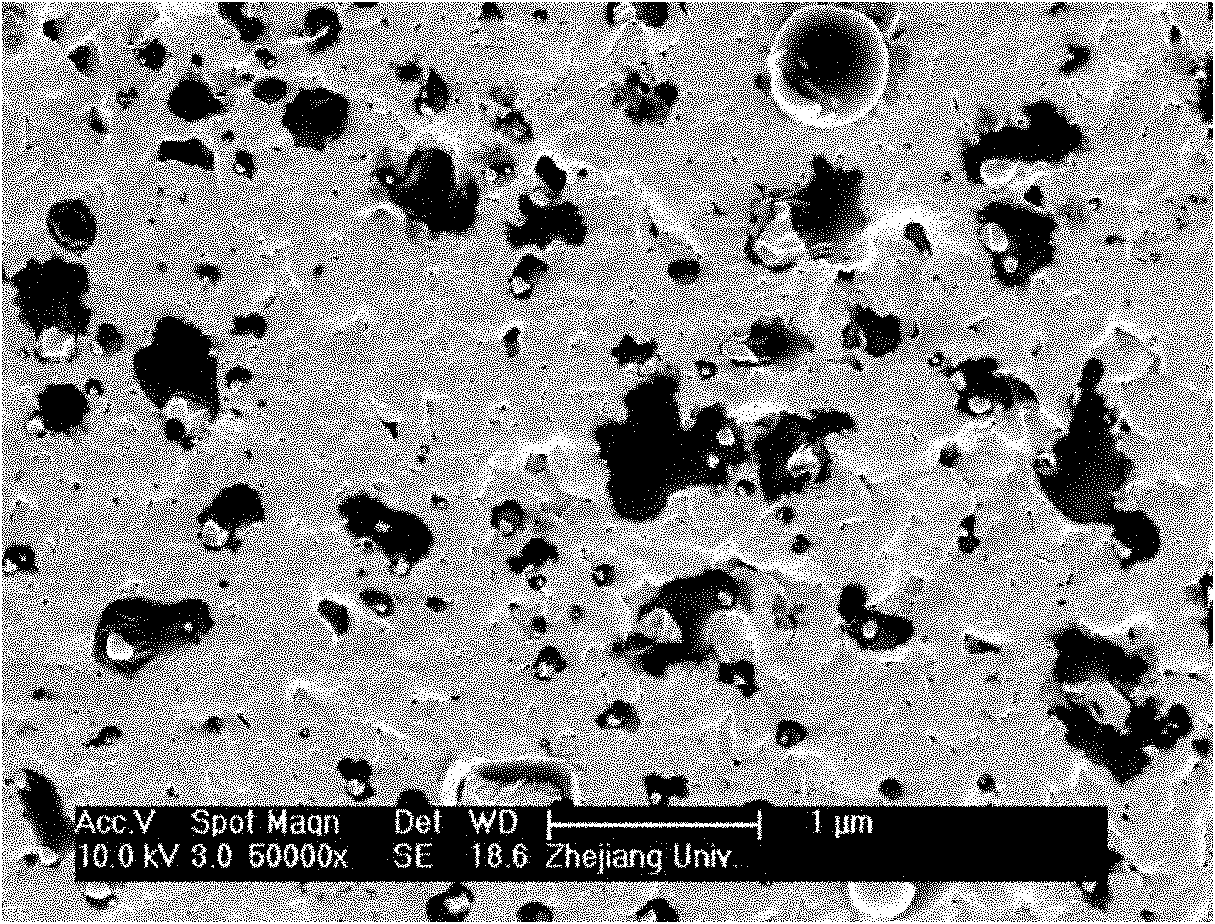

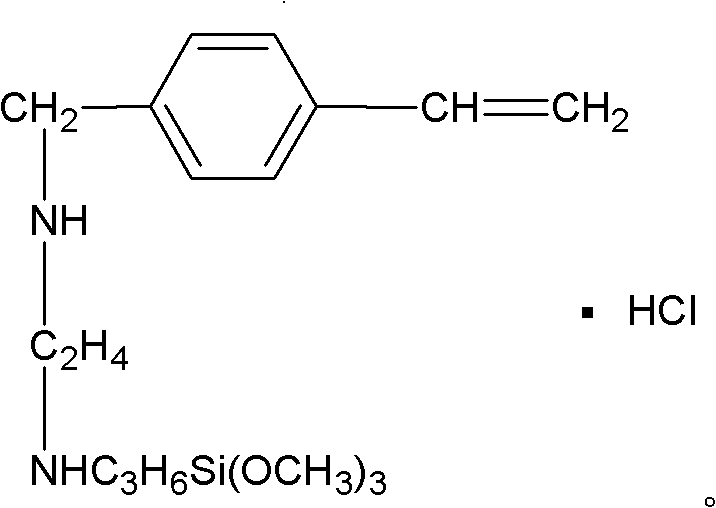

[0042] First, dissolve the silane coupling agent VTSD in ethanol to form a solution with a mass percent concentration of 0.5%, and then spray the solution on the surface of nano-carbon black to form a water film by atomizing and spraying, and then dry it at 50°C Volatilization and heat treatment to prepare nano-carbon black surface-modified by silane coupling agent.

[0043] 10 parts by weight of nano-carbon black surface-modified by a silane coupling agent was mixed with 20 parts by weight of ultra-high molecular weight polyvinyl chloride elastomer (K value 85, average molecular weight 150,000) at 150 ° C to obtain a modified Nano carbon black / polyvinyl chloride compound.

[0044] 70 parts by weight of fluorine rubber is vulcanized in one stage with 0.7 parts by weight of bisphenol AF, 0.35 parts by weight of accelerator benzyltriphenylphosphine chloride (BPP), and 3.5 parts by weight of acid absorbing agent magnesium oxide. After 30 minutes, a section of vulcanized fluoro...

Embodiment 2

[0047] First, dissolve the silane coupling agent VTSD in ethanol to form a solution with a mass percent concentration of 0.1%, and then spray the solution on the surface of nano-carbon black by atomization and spraying to form a water film, and then dry it at 45°C Volatilization and heat treatment to prepare nano-carbon black surface-modified by silane coupling agent.

[0048] 1 weight part of nano-carbon black surface-modified by silane coupling agent is pre-mixed with 9 weight parts of ultra-high molecular weight polyvinyl chloride elastomer (K value is 90, average molecular weight is 200,000) at 190 ° C to obtain a modified Nano carbon black / polyvinyl chloride compound.

[0049] 90 parts by weight of fluorine rubber are vulcanized in one stage with 0.9 parts by weight of bisphenol AF, 0.45 parts by weight of accelerator benzyl triphenylphosphine chloride (BPP), and 4.5 parts by weight of acid absorbing agent magnesium oxide. After 30 minutes, a section of vulcanized fluo...

Embodiment 3

[0052] First, dissolve the silane coupling agent VTSD in ethanol to form a solution with a concentration of 1.0% by mass, and then spray the solution on the surface of nano-carbon black to form a water film, and then dry it at 45°C Volatilization and heat treatment to prepare nano-carbon black surface-modified by silane coupling agent.

[0053] 15 parts by weight of nano-carbon black surface-modified by a silane coupling agent were mixed with 20 parts by weight of ultra-high molecular weight polyvinyl chloride elastomer (K value 90, average molecular weight 200,000) at 180 ° C to obtain a modified Nano carbon black / polyvinyl chloride compound.

[0054] 65 parts by weight of fluorine rubber is vulcanized in one stage with 0.65 parts by weight of bisphenol AF, 0.32 parts by weight of accelerator benzyl triphenylphosphine chloride (BPP), and 3.25 parts by weight of acid absorbing agent magnesium oxide. After 30 minutes, a section of vulcanized fluororubber was obtained.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com