A kind of composite filler based on graphene and preparation method thereof

A composite filler and graphene technology, which is applied in metal material coating technology, coating, gaseous chemical plating, etc., can solve difficult problems such as insurmountable problems, and achieve the effects of easy mass production, simple process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

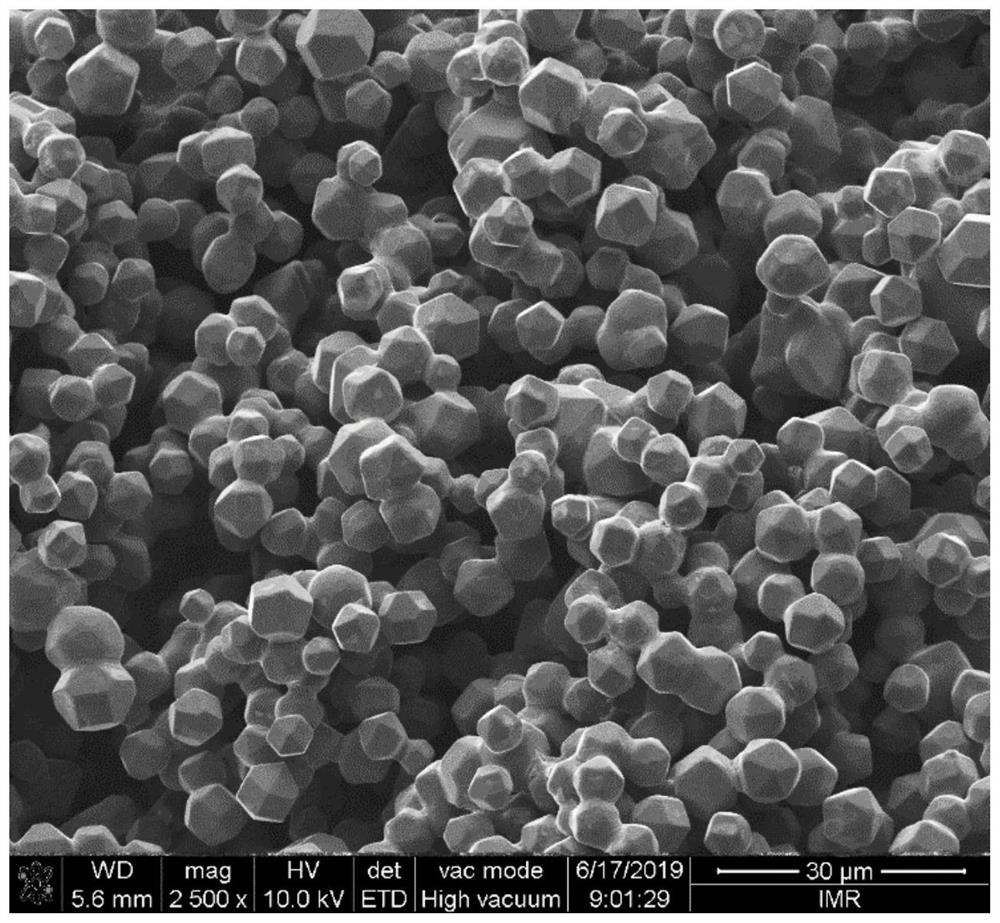

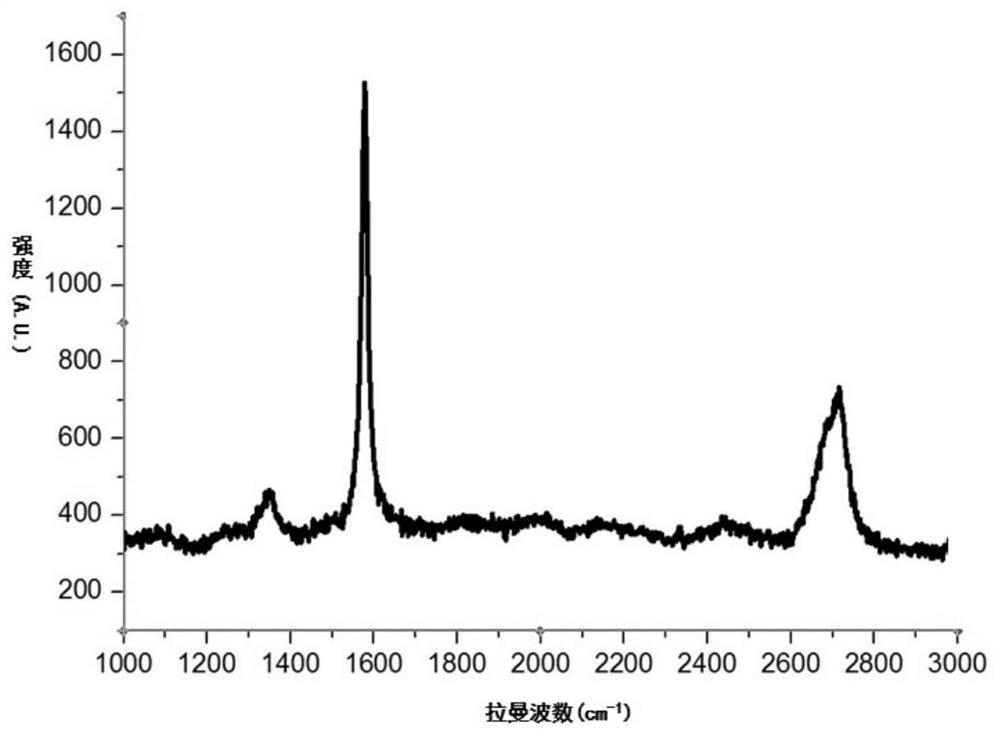

[0049] Heat the reaction furnace cavity to 900°C under a nitrogen protective atmosphere, add 50g of nickel chloride into the constant temperature zone of the reaction furnace cavity, and keep it warm for 2 minutes; feed the mixed gas of methane and hydrogen, and the flow rate of methane and hydrogen in the mixed gas The ratio is 1:50, the reaction time is 3min, and graphene is catalyzed on the surface of the reduced nickel chloride substrate. The prepared reactant was taken out under a nitrogen protective atmosphere. The resulting product is polyhedral (e.g. figure 1 ), with an average particle size of 6 μm. The prepared reactant was put into 3mol / L hydrochloric acid aqueous solution (etching solution), and kept at 80° C. for 30 min to completely remove the nickel in the graphene polyhedron, and filter the graphene powder After extraction, cleaning and drying, the hollow graphene particles with a few tiny micropores on the surface are obtained, and the structure is as follow...

Embodiment 2

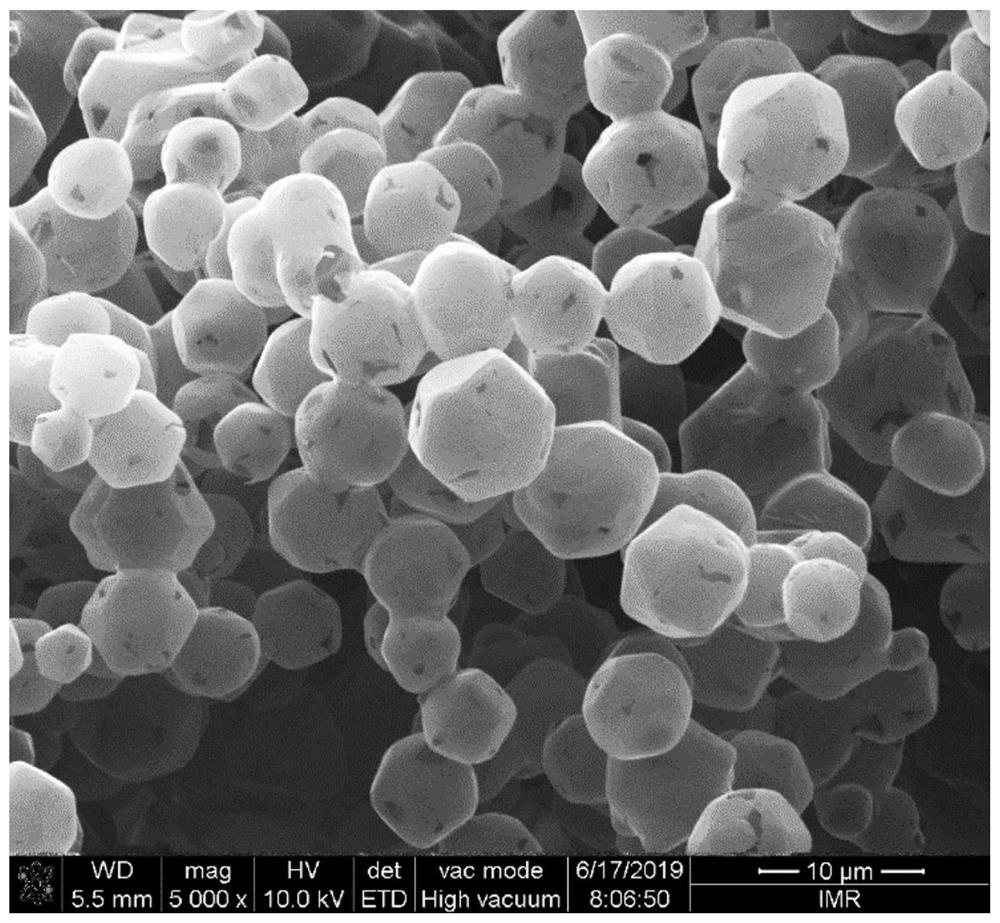

[0052] Under the protective atmosphere of argon, the reaction furnace cavity was heated to 900°C, 50g of nickel chloride was added to the constant temperature zone of the reaction furnace cavity, and kept for 2 minutes; the mixed gas of methane, hydrogen and argon was introduced, and the methane 1. The volume flow ratio of hydrogen and argon is 1:10:80, and the reaction time is 5 minutes, and the graphene is catalyzed and grown on the surface of the reduced nickel chloride substrate. The prepared reactant was taken out under an argon protective atmosphere. The resulting product is spherical (e.g. Figure 7 ), with an average particle size of 3 μm. The prepared reactant was put into 3mol / L hydrochloric acid aqueous solution (etching solution), and kept at 80° C. for 30 min to completely remove the nickel in the graphene polyhedron, and filter the graphene powder After extraction, cleaning and drying, graphene microspheres with hollow cavities are obtained.

Embodiment 3

[0054] Under the protective atmosphere of argon, the reaction furnace cavity was heated to 1000°C, 50g of copper sulfate was added to the constant temperature zone of the reaction furnace cavity, and kept for 2 minutes; the mixed gas of methane, hydrogen and argon was introduced, and the methane, The volume flow ratio of hydrogen and argon is 1:30:100, the reaction time is 20 minutes, and the graphene is catalyzed on the surface of the reduced copper sulfate substrate. The prepared reactant was taken out under an argon protective atmosphere. The resulting product is spherical (e.g. Figure 8 ), with an average particle size of 1 μm. Put the prepared reactant into 2mol / L sulfuric acid aqueous solution (etching solution), keep it warm at 80°C for 60min, completely remove the copper in the graphene polyhedron, and filter out the graphene powder , cleaning and drying to obtain graphene particles with hollow cavities.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com