Precast expanding pile as well as construction method and construction mechanical equipment thereof

A construction method, technology of extruded and expanded piles, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of complex construction technology, high cost, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

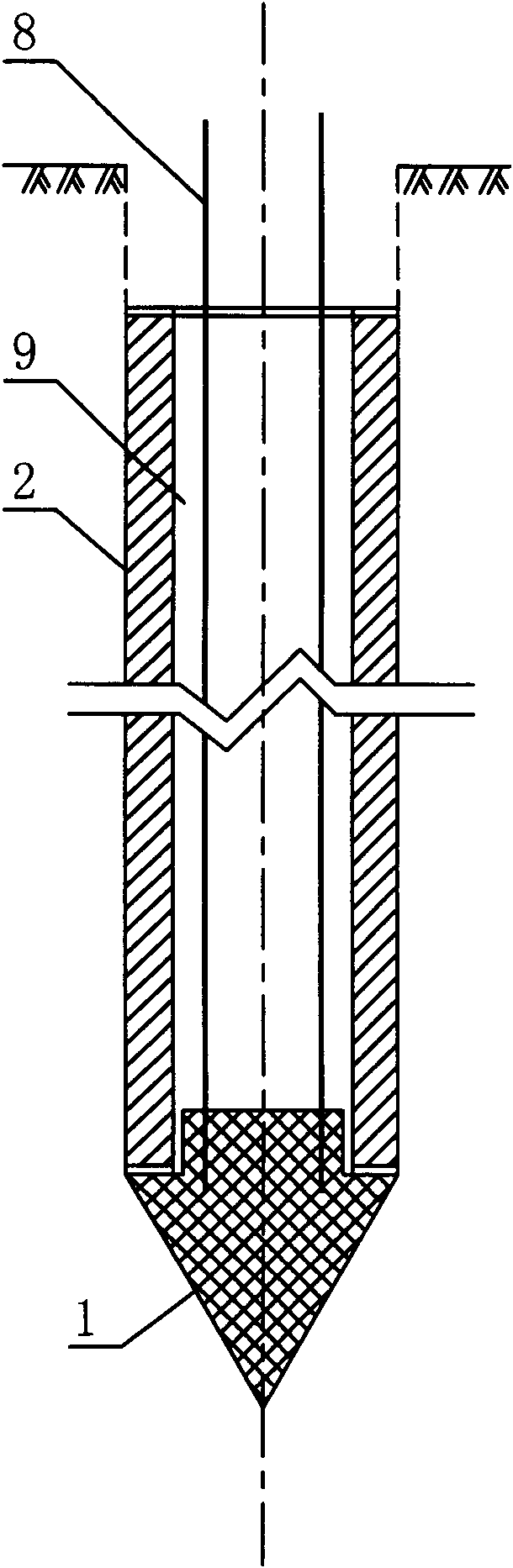

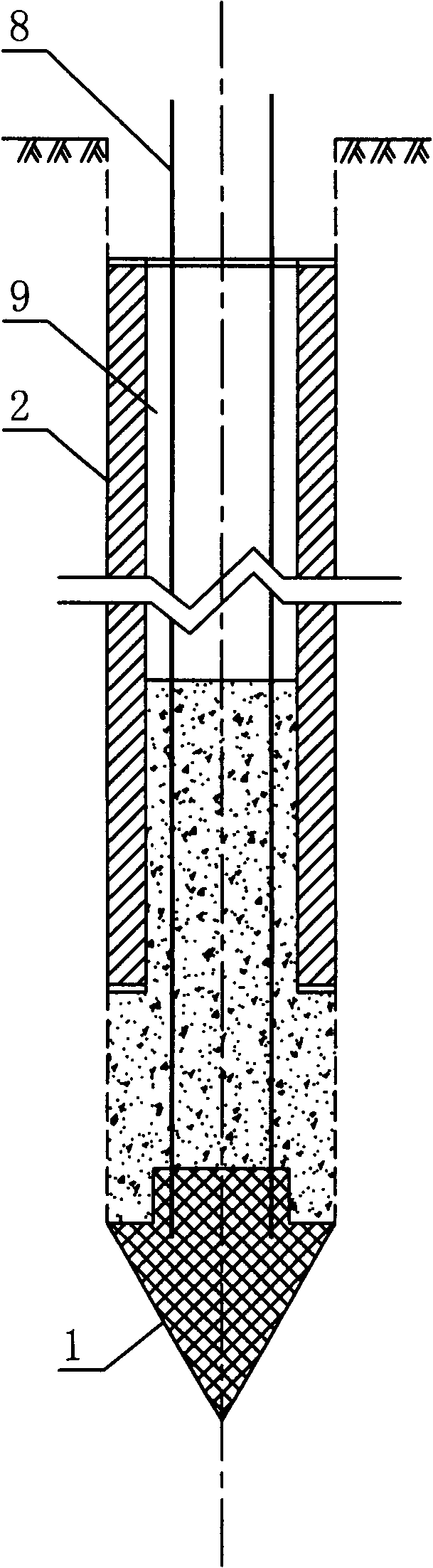

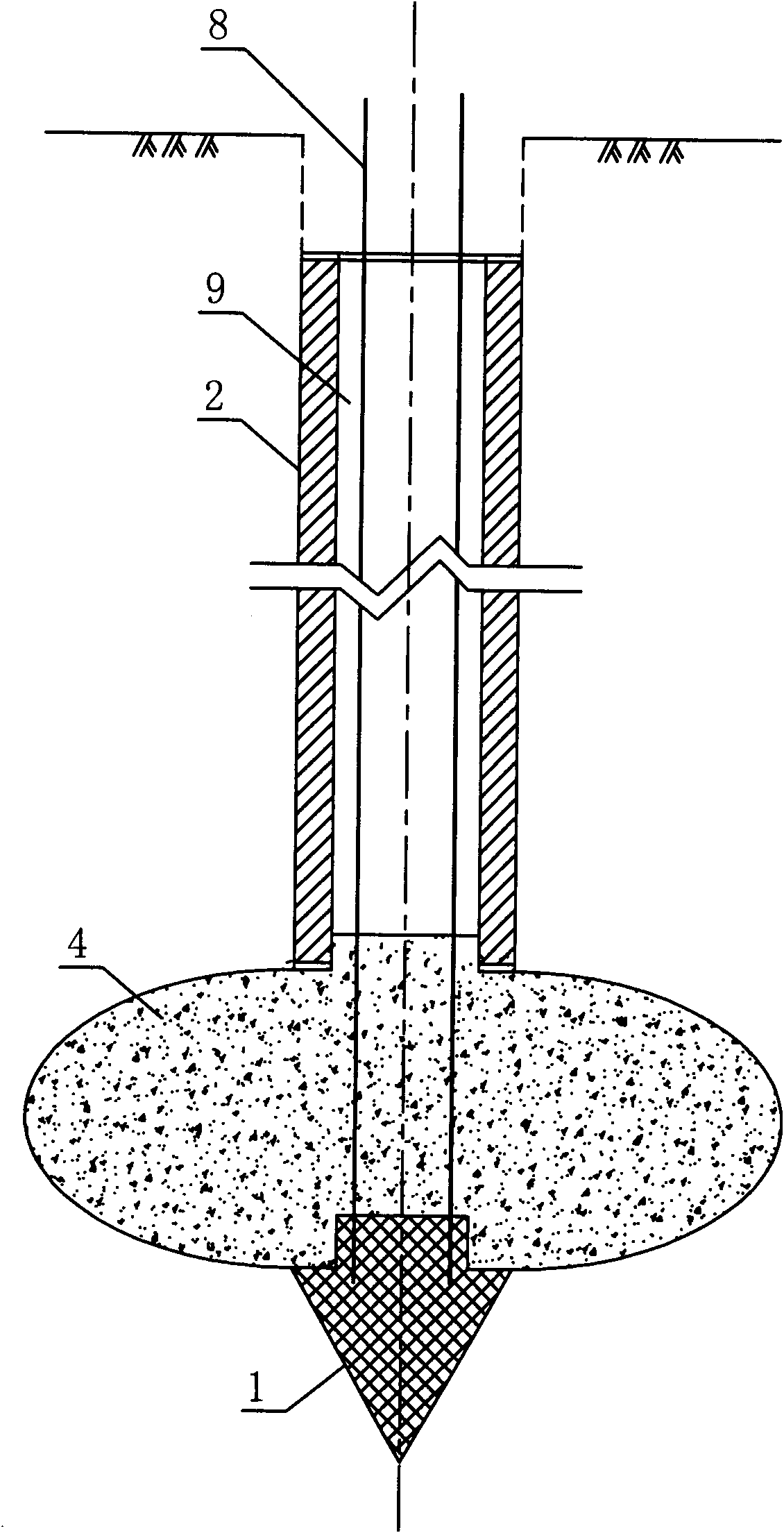

[0028] As the present invention such as Figure 1 to Figure 4 The main purpose of the shown embodiment is to introduce the construction method of prefabricated extruded and expanded piles, the principle of extruded and expanded, the structure of the prefabricated extruded and expanded piles formed after extruded and expanded, and the construction of pile-forming machines and expanders used in the extruded and expanded construction process. Structural construction and how it works. In the first step of the prefabricated extruded and expanded pile construction method introduced in this embodiment, after determining the pile position, the pile plug (1) is connected to the bottom of the hollow prefabricated pile (2), and the pile plug (1) can be as follows figure 1 The solid prefabricated pile tip shown can also be a plate structure covered at the bottom of the hollow prefabricated pile (2), or a tubular structure inserted into the bottom opening of the hollow part (9) of the holl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com