Crashed stone grouting pile with lead holes implanted in cloth bag and construction method

A technology of grouting piles and crushed stones, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of reduced pile bearing capacity, polluted gravel, and impact on buildings, so as to enhance bearing performance and reduce engineering costs. The effect of lowering the cost and improving the load-carrying performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. While the invention will be described in conjunction with the preferred embodiments, it will be understood that it is not intended to limit the invention to the described embodiments. On the contrary, the invention is to cover alternatives, modifications and equivalents, which may be included within the scope of the invention as defined by the appended claims.

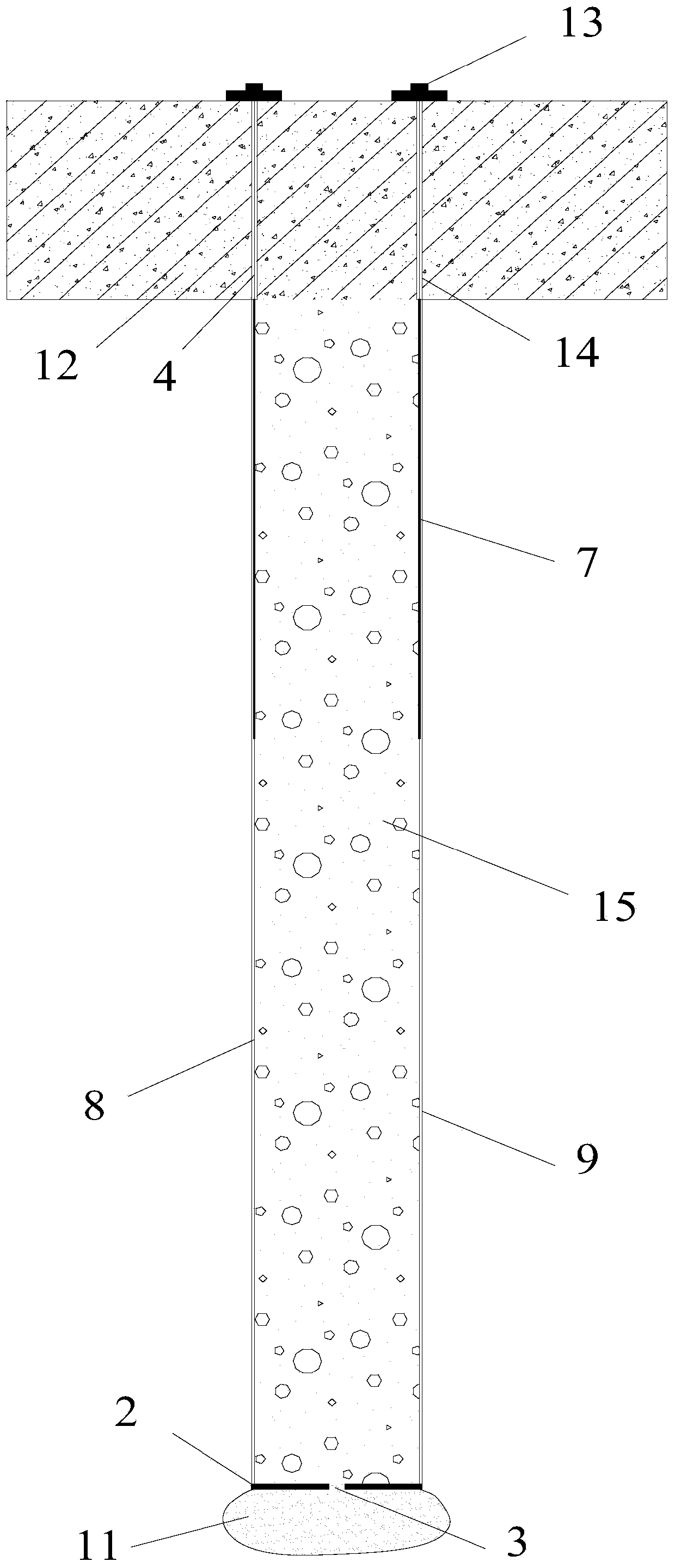

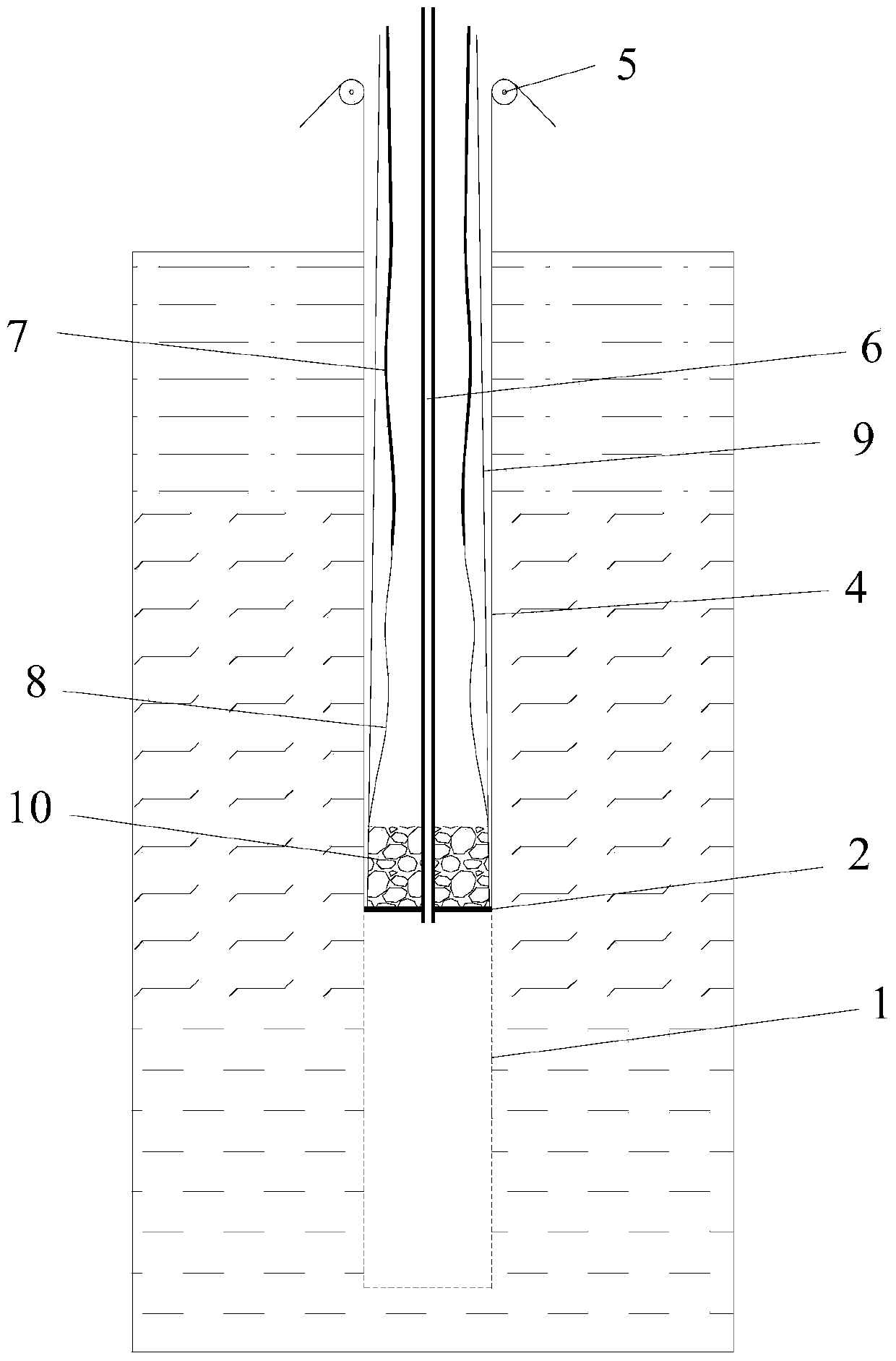

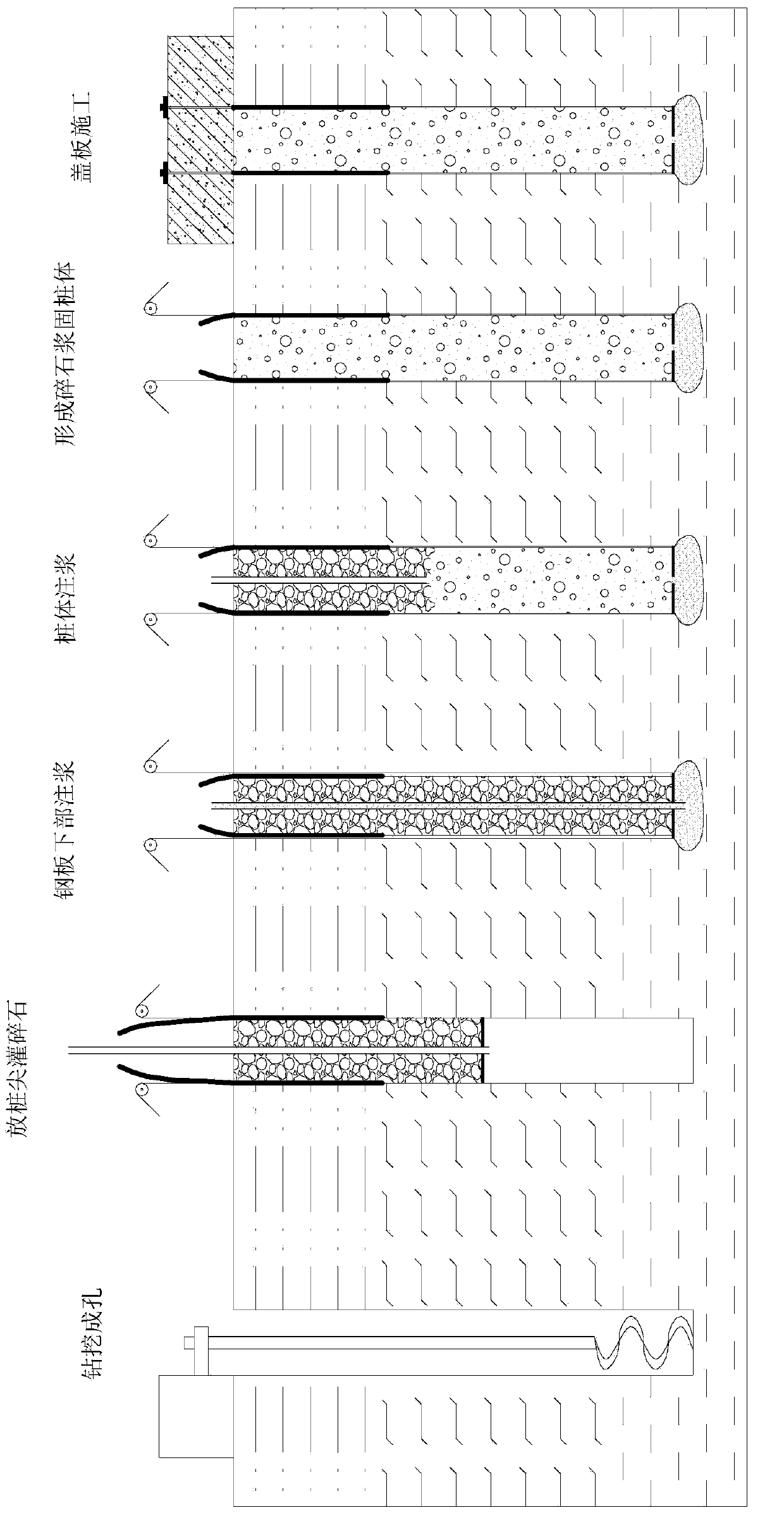

[0039] Implementation of the present invention refers to Figure 1 to Figure 3 As shown, the present invention first forms holes and then implants bagged crushed stone grouting pile structure mainly consists of: prefabricated pile tip 2, steel strand 4, carbon fiber cloth bag 7, geotechnical cloth bag 8, pile end slurry solid 11 and cover plate 12.

[0040] In this example, the diameter of the pile hole is 500 mm, and the prefabricated pile point 2 adopts a circular steel sheet pile point, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com