Steel pipe concrete pile

A technology of steel pipe concrete and concrete, which is applied in the field of building materials, can solve the problems of high production cost and complex structure of pipe piles, and achieve the effect of fast pile formation, strong hammer resistance, and improved bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

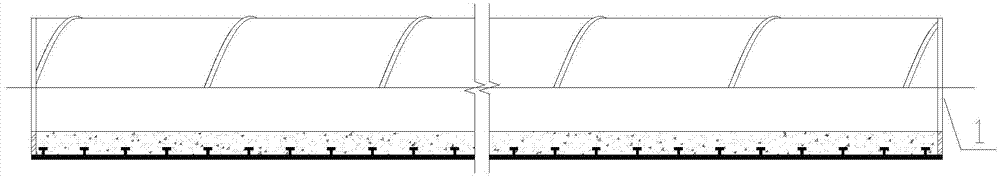

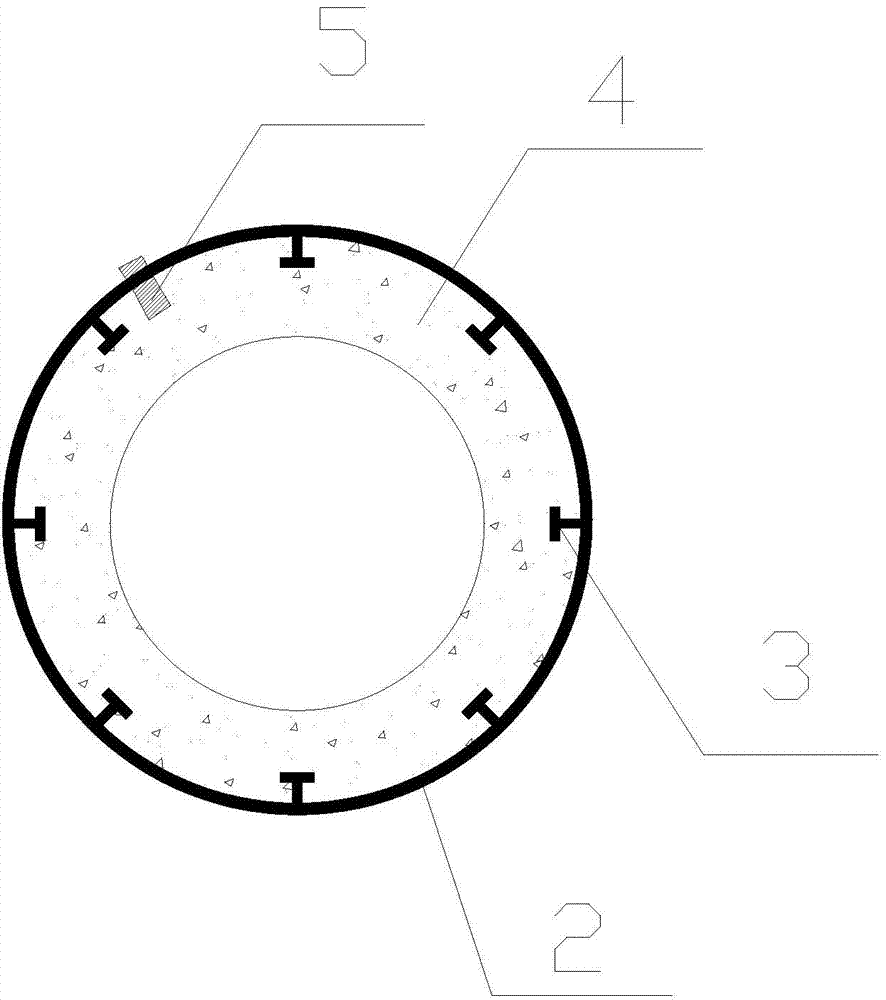

[0029] Such as figure 1 , figure 2 As shown, a concrete-filled steel pipe pile includes an outer steel pipe 2, a spiral rib 5 is fixed on the inner and outer walls of the outer steel pipe 2, and multiple rings of anchors 3 are fixed along the circumference of the inner wall of the outer steel pipe 2. The inner steel pipe 2 is lined with concrete 4, and the end of the outer steel pipe 2 is provided with an end plate 1; the design of the structure of the present invention makes the bite force between the outer steel pipe 2 and the concrete 4 include three parts: the spiral rib 5 and the concrete 4 Engagement force, the anchoring force between the anchor 3 and the concrete 4, the bonding force between the inner wall of the outer steel pipe 2 and the concrete 4, the increased spiral rib 5 and the anchor 3 can greatly improve the bonding between the concrete 4 and the steel pipe, and the combination It is strong, and the anti-strike ability is enhanced, and the concrete and the s...

Embodiment 2

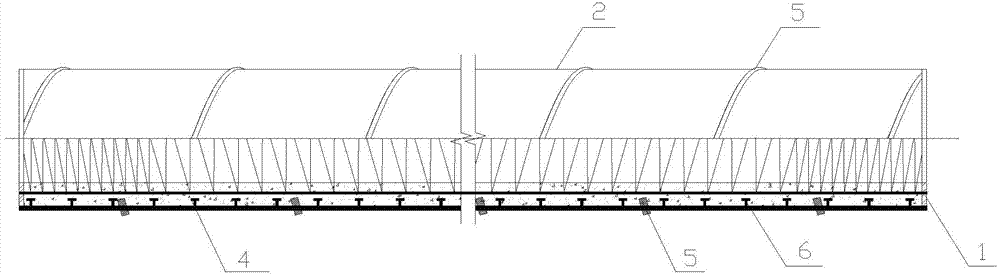

[0038] Such as image 3 , Figure 4 As shown, a concrete-filled steel pipe pile includes an outer steel pipe 2, a spiral rib 5 is fixed on the inner wall of the outer steel pipe 2, and multiple rings of anchors 3 are fixed along the circumference of the inner wall of the outer steel pipe 2. The steel pipe steel pipe 2 is lined with concrete 4, and the end of the outer steel pipe 2 is provided with an end plate 1; the design of the structure of the present invention makes the bite force between the outer steel pipe 2 and the concrete 4 include three parts: the engagement of the spiral rib 5 and the concrete 4 force, the anchoring force between the anchor 3 and the concrete 4, the bonding force between the inner wall of the outer steel pipe 2 and the concrete 4, the increased spiral rib 5 and the anchor 3 can greatly improve the bonding between the concrete 4 and the outer steel pipe 2 , the combination is firm, the anti-strike ability is enhanced, and the concrete and the stee...

Embodiment 3

[0040] Such as Figure 5 As shown, a concrete-filled steel pipe pile includes an outer steel pipe 2, a spiral rib 5 is fixed on the inner wall of the outer steel pipe 2, and multiple rings of anchors 3 are fixed along the circumference of the inner wall of the outer steel pipe 2. The steel pipe steel pipe 2 is lined with concrete 4, and the end of the outer steel pipe 2 is provided with an end plate 1; the design of the structure of the present invention makes the bite force between the steel pipe and the concrete include three parts: the meshing force between the spiral rib 5 and the concrete 4, the anchor The anchoring force between 3 and concrete 4, the bonding force between the inner wall of steel pipe and concrete 4, the added spiral rib 5 and anchor 3 can greatly improve the bonding between concrete 4 and steel pipe, the combination is firm, the anti-strike ability is enhanced, and the blow The concrete 4 and the steel pipe will not be separated during the process. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com