Rotary-digging combined pile-forming construction method in complicated geological conditions

A technology with complex geological conditions and construction methods, applied in the field of foundation construction, can solve the problems that the piling process cannot be applied to cities, cannot be arranged in mud pools, and the geological conditions are complicated, and achieve stable and reliable pile quality, strong stratum adaptability, The effect of piling shape rules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

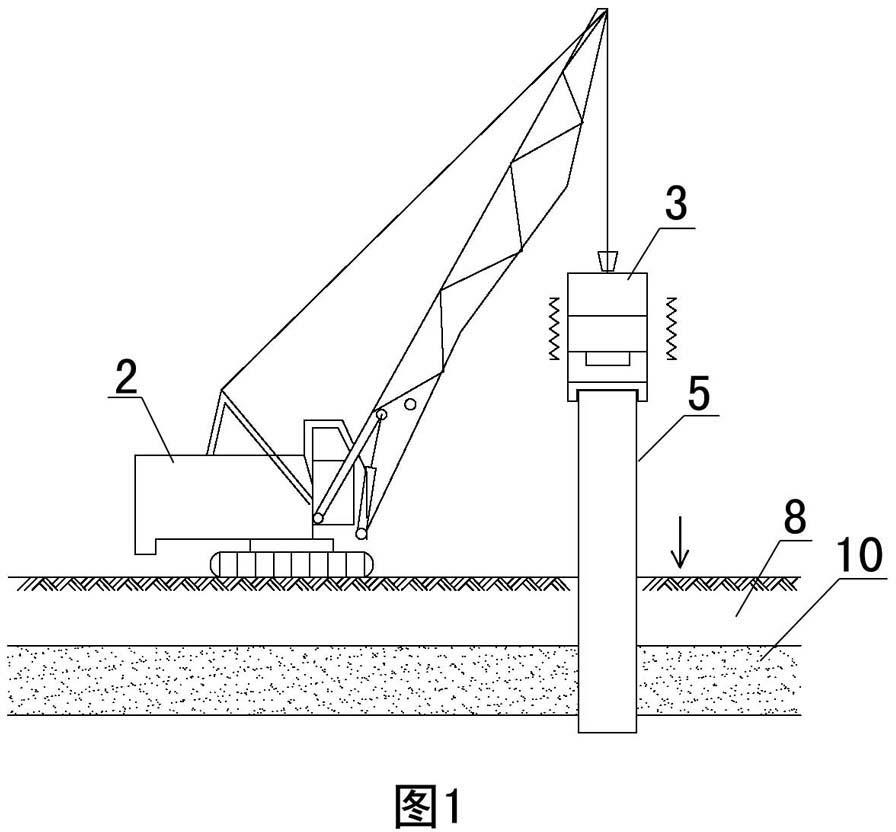

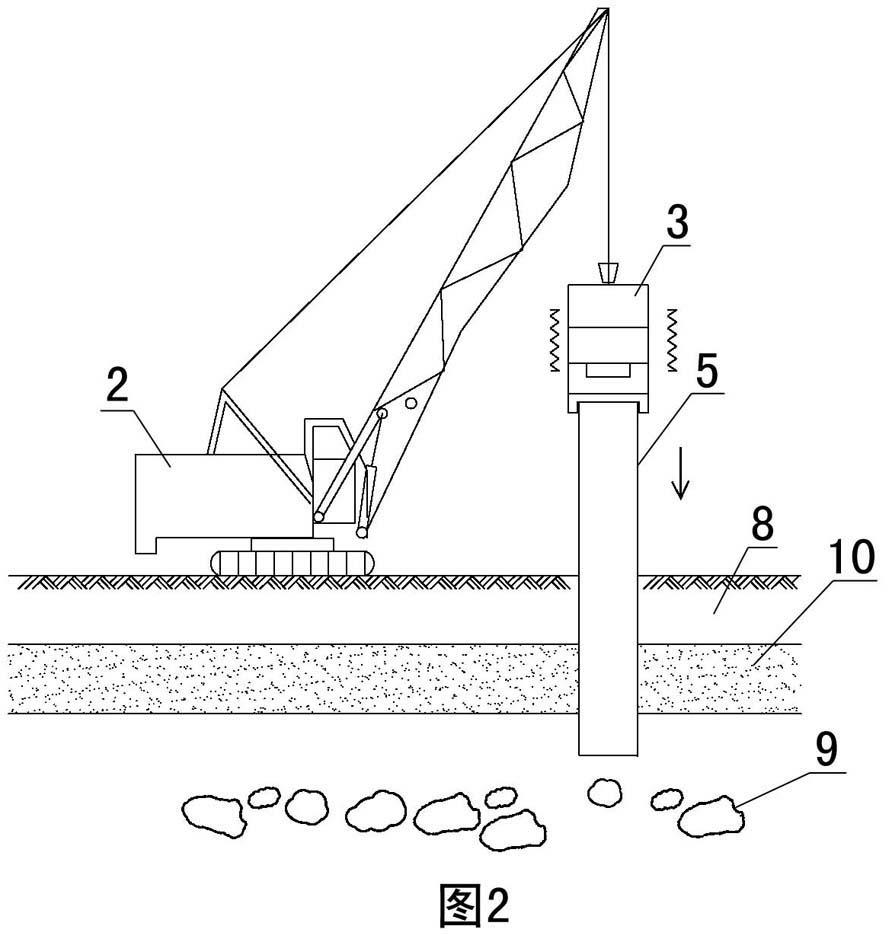

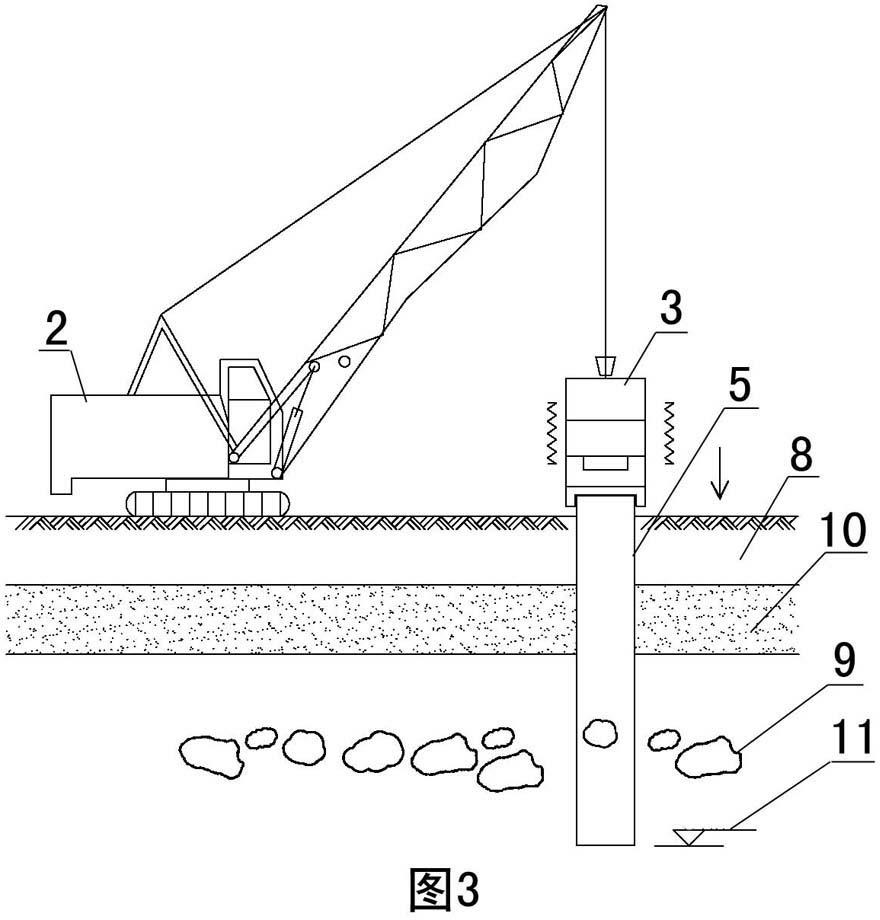

[0040] Embodiment one sees Figure 1-9 As shown, the construction method of rotary excavation combined with piles under complex geological conditions, the construction steps are as follows.

[0041] Step 1. Pile foundation positioning; in this embodiment, the cross positioning method is used for pile foundation positioning. Before the drilling rig is in place, gravel should be filled and compacted around the pile position to ensure that the drilling rig does not fall during the drilling process. Sink and tilt, and then adjust the drill bit and drill pipe through the automatic control device of the drilling rig, so that they can be accurately aligned with the cross line, and the inclination of the drill pipe is less than 1%.

[0042] Step 2: Use the distance intersection method to locate the steel casing. The cross line center method is a conventional method for embedding and checking the casing. This method is intuitive, but lacks process control during the embedding process. T...

Embodiment 2

[0054] Embodiment two see Figure 10-18 As shown, the construction method of rotary excavation combined with piles under complex geological conditions, the construction steps are as follows.

[0055] Step one, pile foundation positioning. In this embodiment, the cross positioning method is used for the positioning of the pile foundation. Before the drilling rig is in place, gravel should be filled and compacted around the pile to ensure that the drilling rig does not sink or tilt during the drilling process. The automatic adjustment device is used to adjust the drill bit and the drill pipe so that they are precisely aligned with the crosshairs, and the inclination of the drill pipe is less than 1%.

[0056] Step 2: Use the distance intersection method to locate the steel casing. The cross line center method is a conventional method for embedding and checking the casing. This method is intuitive, but lacks process control during the embedding process. The present invention ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com