Bidirectional helix extruding-enlarging pile construction method and bidirectional helix closed extruding-enlarging aiguille

A technology of two-way helix and construction method, applied in drill bits, earthwork drilling, drilling equipment and methods, etc., can solve the problems of underestimation of pile bearing capacity, safety problems, consumption, etc., and achieve the improvement of bearing and deformation performance, strength and The effect of improving deformation characteristics and increasing soil bearing capacity of pile end

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

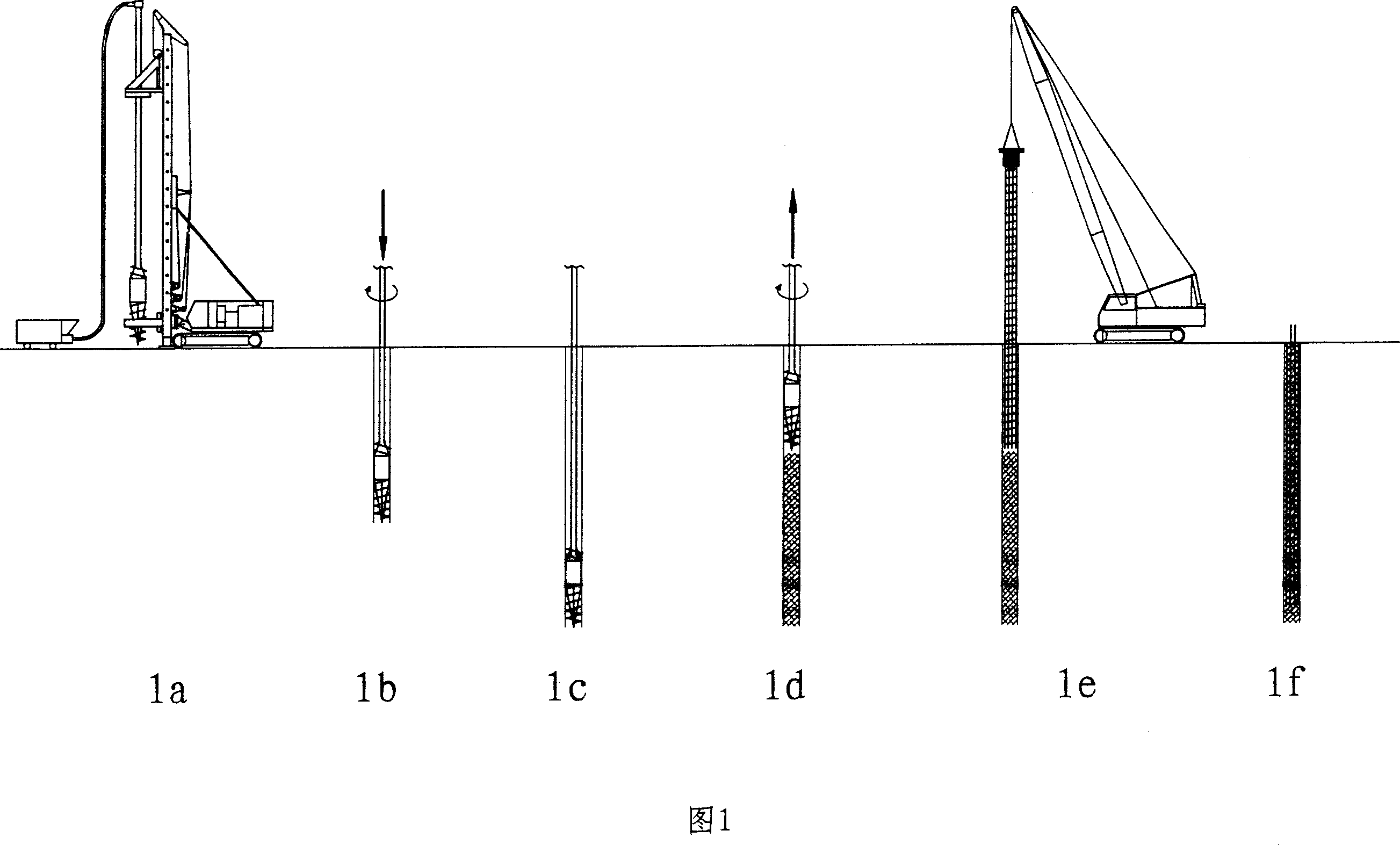

[0079] As shown in Fig. 1a~1f in Fig. 1, the construction method of two-way spiral extrusion expansion pile of the present invention comprises the following construction steps:

[0080] 1) The pile drilling rig equipped with the two-way helical closed-extrusion and expansion drill bit is put in place according to the known method, the concrete pump is prepared, and the pile material to be poured is prepared. The pile material is any one of concrete pile material or cement fly ash gravel pile material or tailings mortar pile material or cement steel slag pile material, and the cement fly ash gravel pile material is CFG pile material.

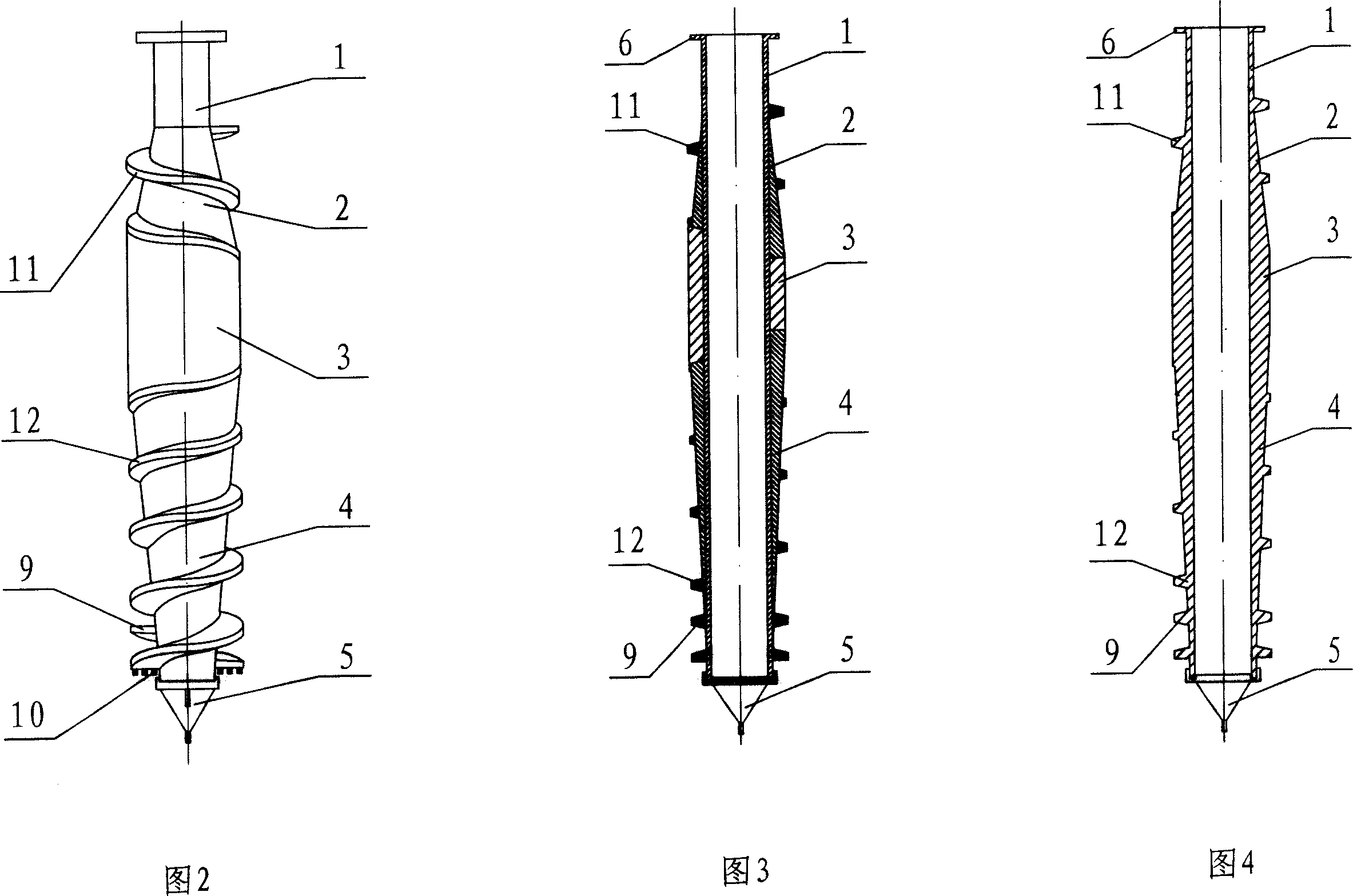

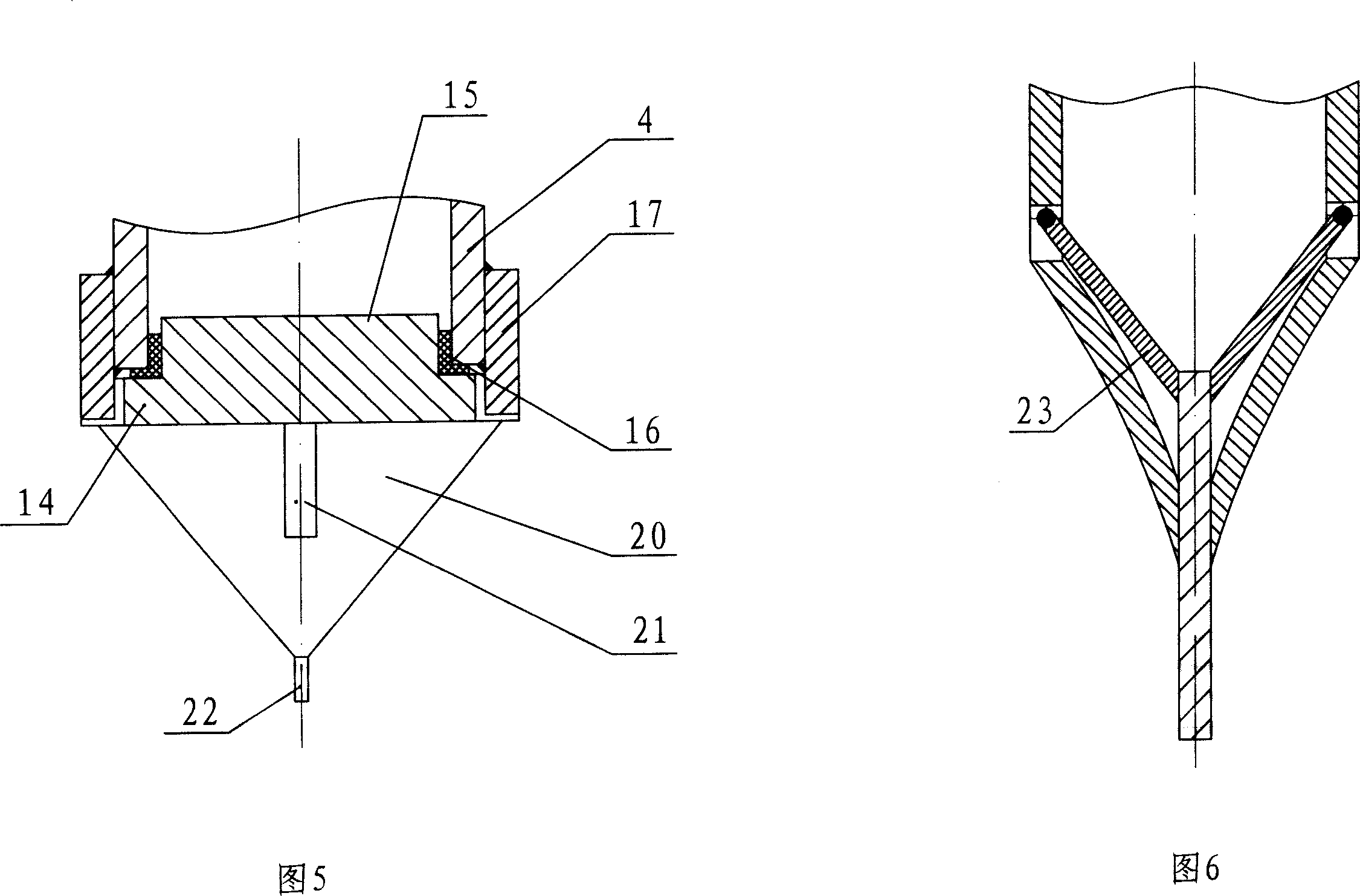

[0081] 2) After the piling rig installed with the two-way helical closed extrusion drill bit is in place, start the pile drilling rig to apply clockwise torque and downward axial pressure, and use the two-way helical closed extrusion drill bit to drill and expand. Holes, make the two-way helical closed extruding and expanding drill bit rotate dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com