Method for bracing foundation pit by using steel box piles

A foundation pit enclosure and steel box technology, applied in excavation, sheet pile walls, foundation structure engineering, etc., can solve the problems of inevitable environmental pollution, difficult construction quality assurance, and large environmental impact, so as to protect the environment, The injection range is easy to control and the construction period is short

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0051] The method for using steel box piles to protect foundation pits includes the following steps:

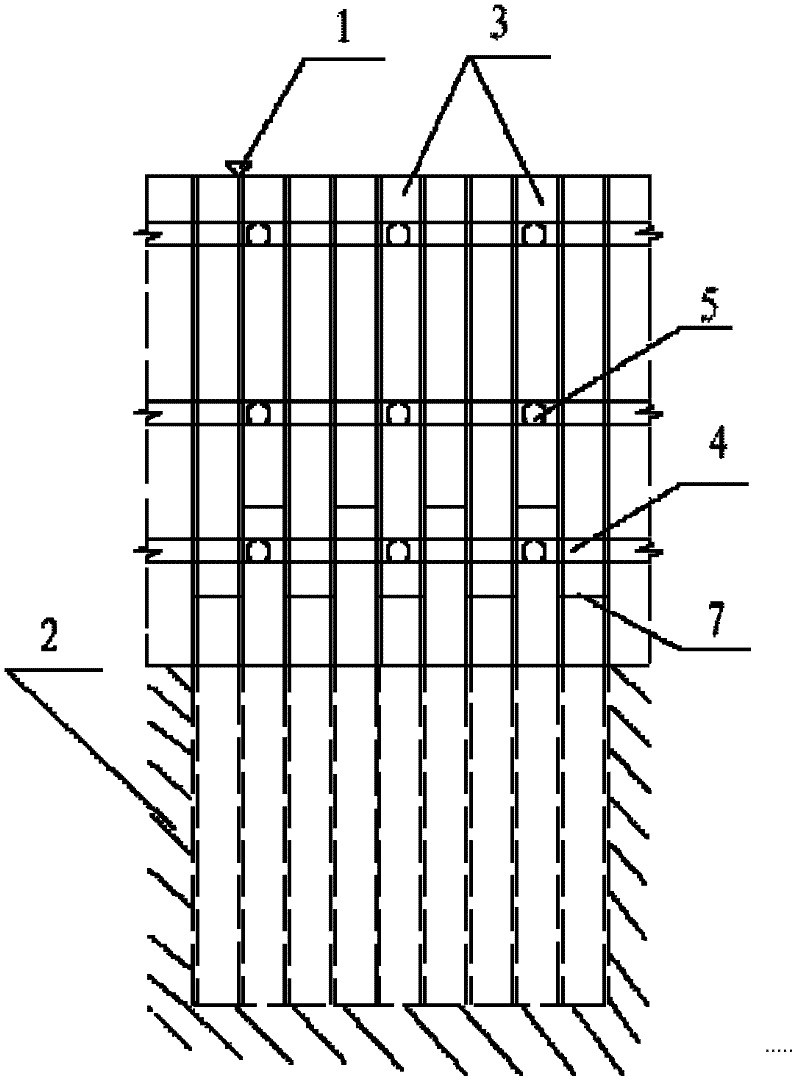

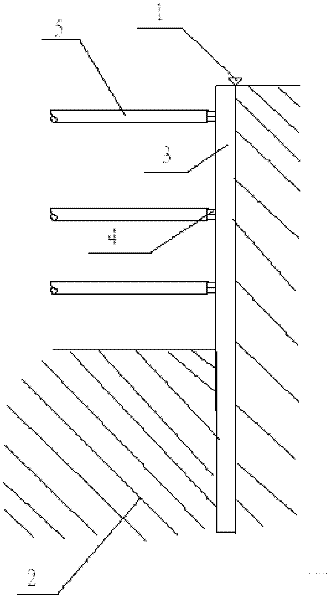

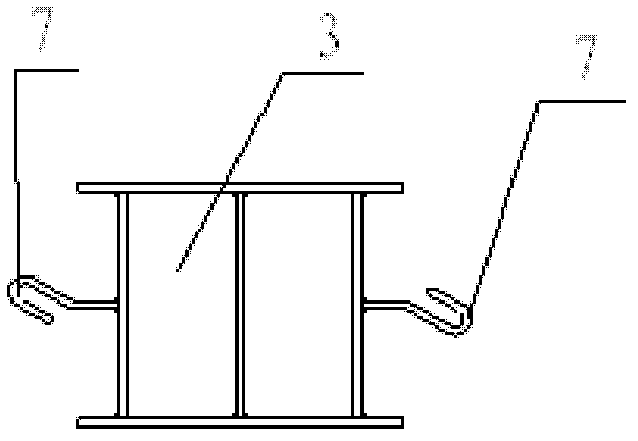

[0052] First, make steel box piles: steel box piles of prefabricated dimensions are welded by section steel or steel plates, such as figure 1 , figure 2 and image 3 As shown, the finished steel box pile box 3 is formed, and the two sides of the steel box pile box 3 are symmetrically provided with connecting members 7 for connecting horizontally adjacent steel box piles. The side of 3 is welded with a hook-shaped plug-in connecting member with a long length, so that the adjacent steel box piles are connected to each other, and the interface of the connecting member of the previous steel box pile becomes the sinking pile of the next steel box pile The guide groove. The hook-shaped socket-type connecting member between the piles is "hinged",...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com