Drilling tool for two-way soil-cement mixed pile

A two-way mixing, cement-soil technology, used in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of poor pile forming effect, impact on pile quality, and increased pile driver load, and achieve construction efficiency and pile forming. The effect of improving the quality, ensuring the quality of piles and increasing the number of stirring times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

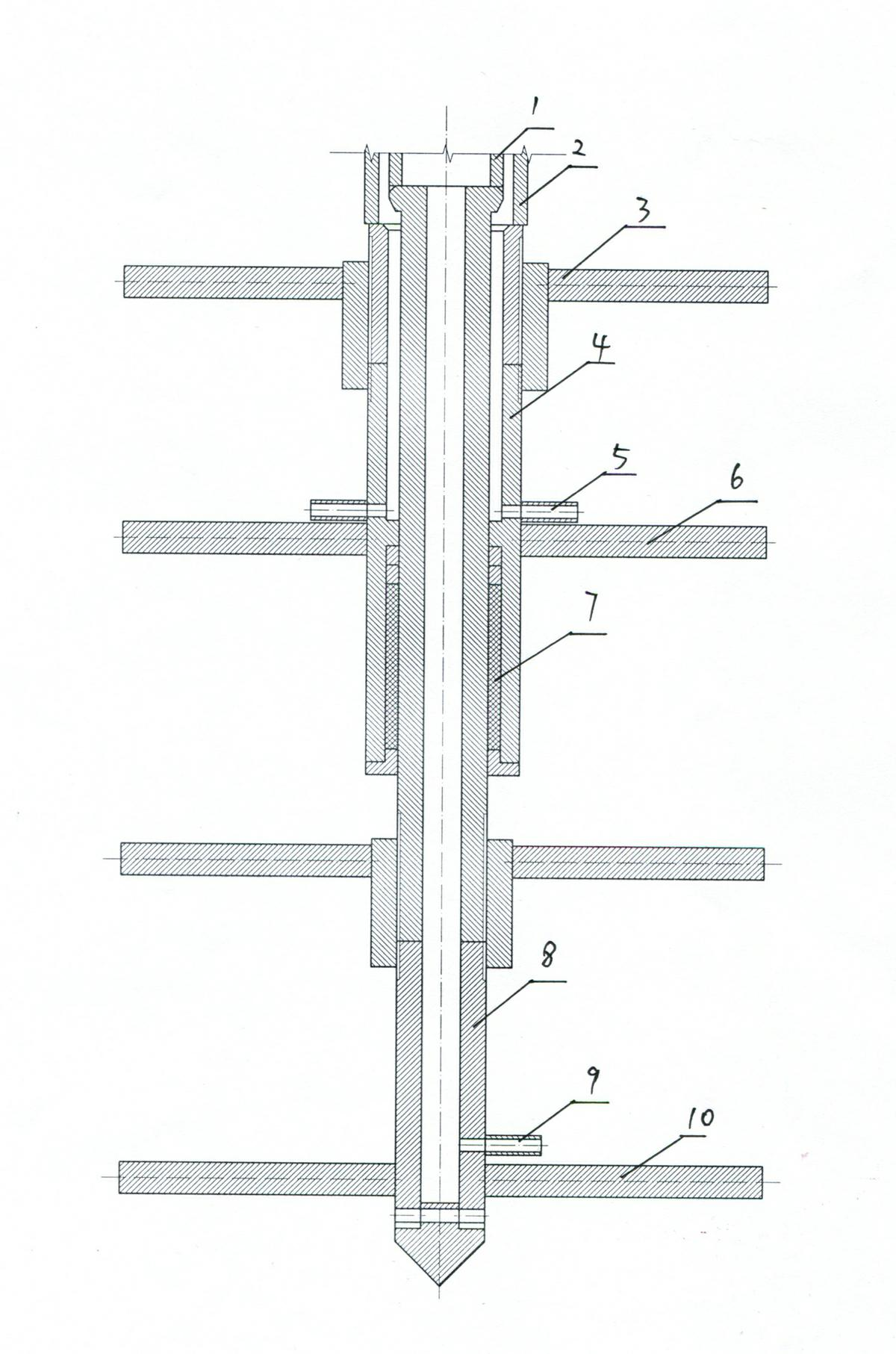

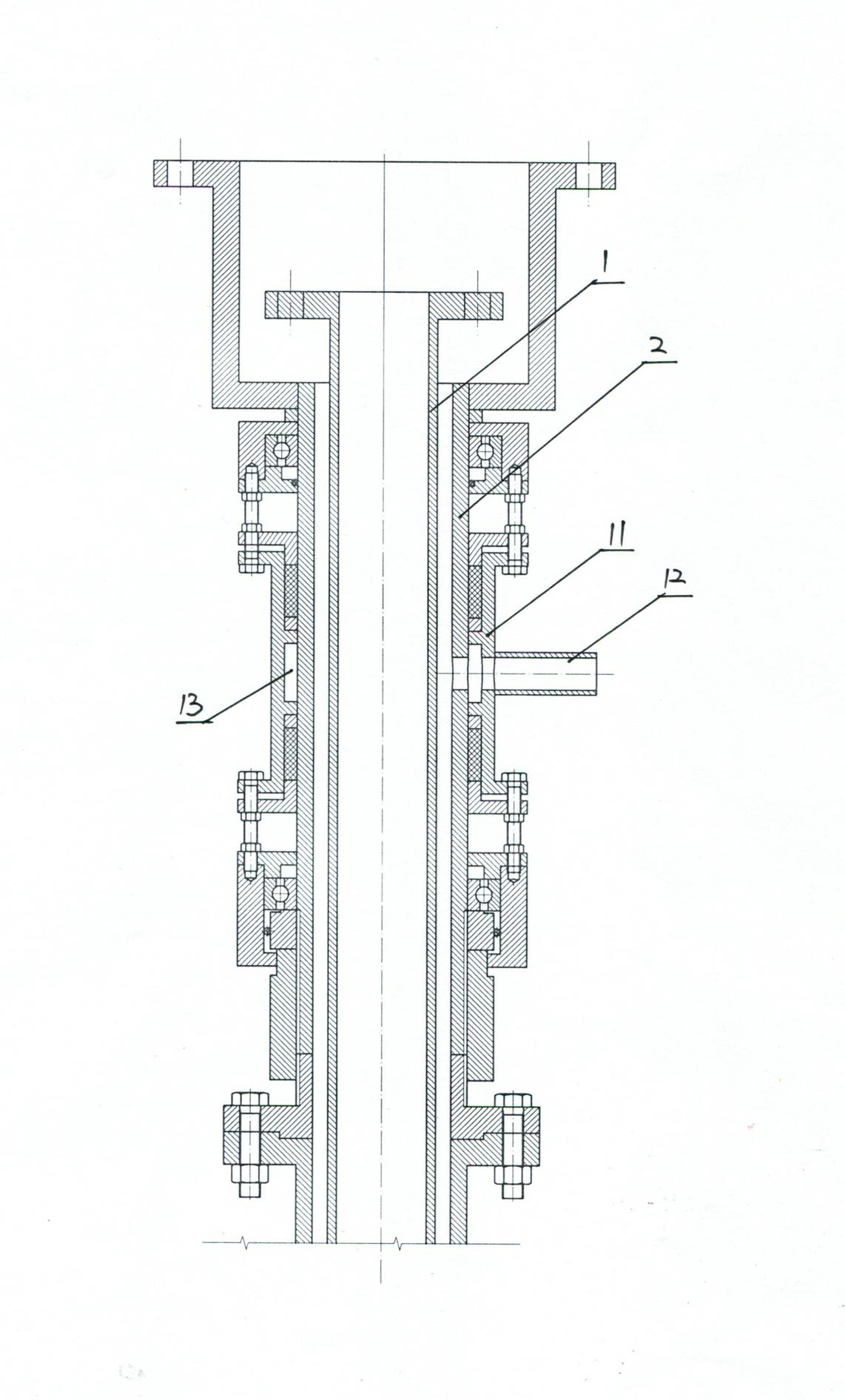

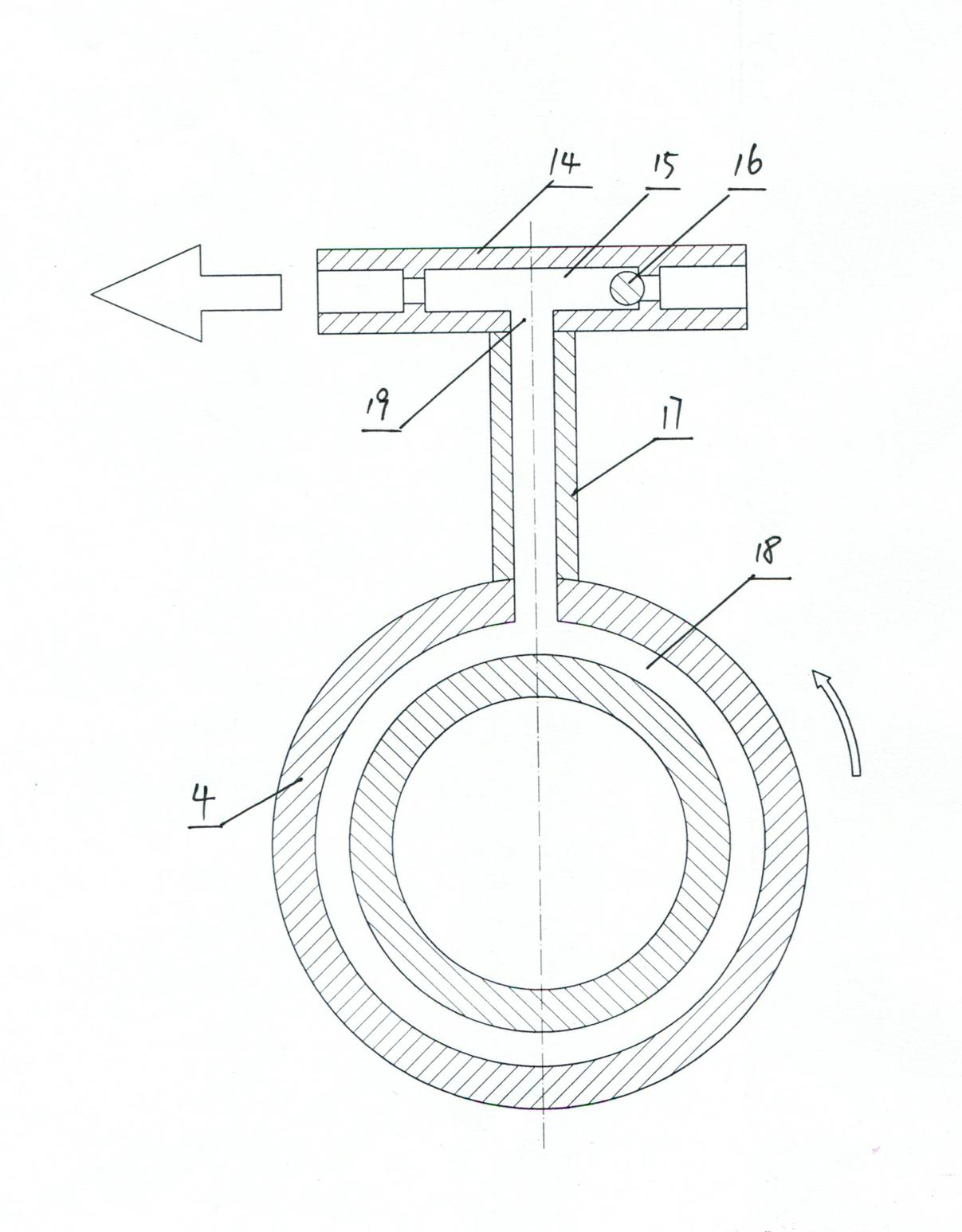

[0011] A cement-soil two-way mixing pile drilling tool, comprising inner and outer drill pipes and inner and outer drill bits, a water and air injection device is provided on the upper part of the outer drill pipe 2, and the water and air injection device includes a rotating ring 11 arranged on the outer drill pipe, which rotates The inner wall of the ring 11 is provided with a circle of grooves 13, and the outer wall of the rotating ring 11 is provided with a water injection air pipe 12 communicating with the above grooves, and the outer drill pipe corresponding to the groove of the rotating ring 11 is provided with a hole for entering water and air. , the cavity between the outer drill pipe 2 and the inner drill pipe 1 is set as a passage 15 for water and air to descend, the outer drill bit includes an outer drill core tube 4, and at least two layers of stirring blades are arranged on the outer drill core tube 4, and the outer drill bit The upper end of the core pipe 4 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com