Strengthening and reinforcing mountain piling construction method for underground pile foundation cavern

A construction method and technology for pile foundations, which are applied in basic structure engineering, chemical instruments and methods, filling and other directions, can solve problems such as geological disasters, damage to piling equipment, casualties, etc., to reduce the strength of mountain piles and ensure stability. , the effect of increasing the amount of grouting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

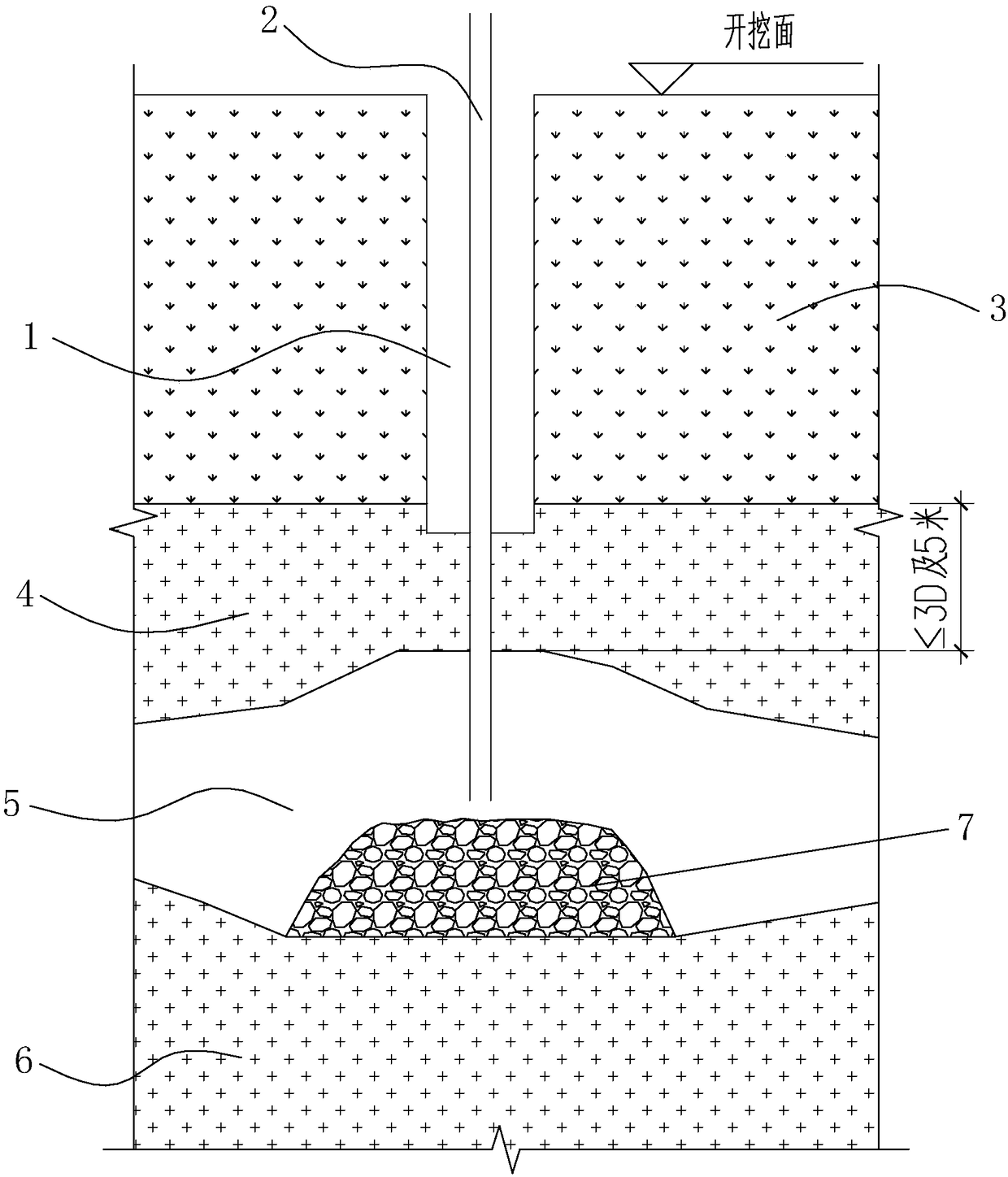

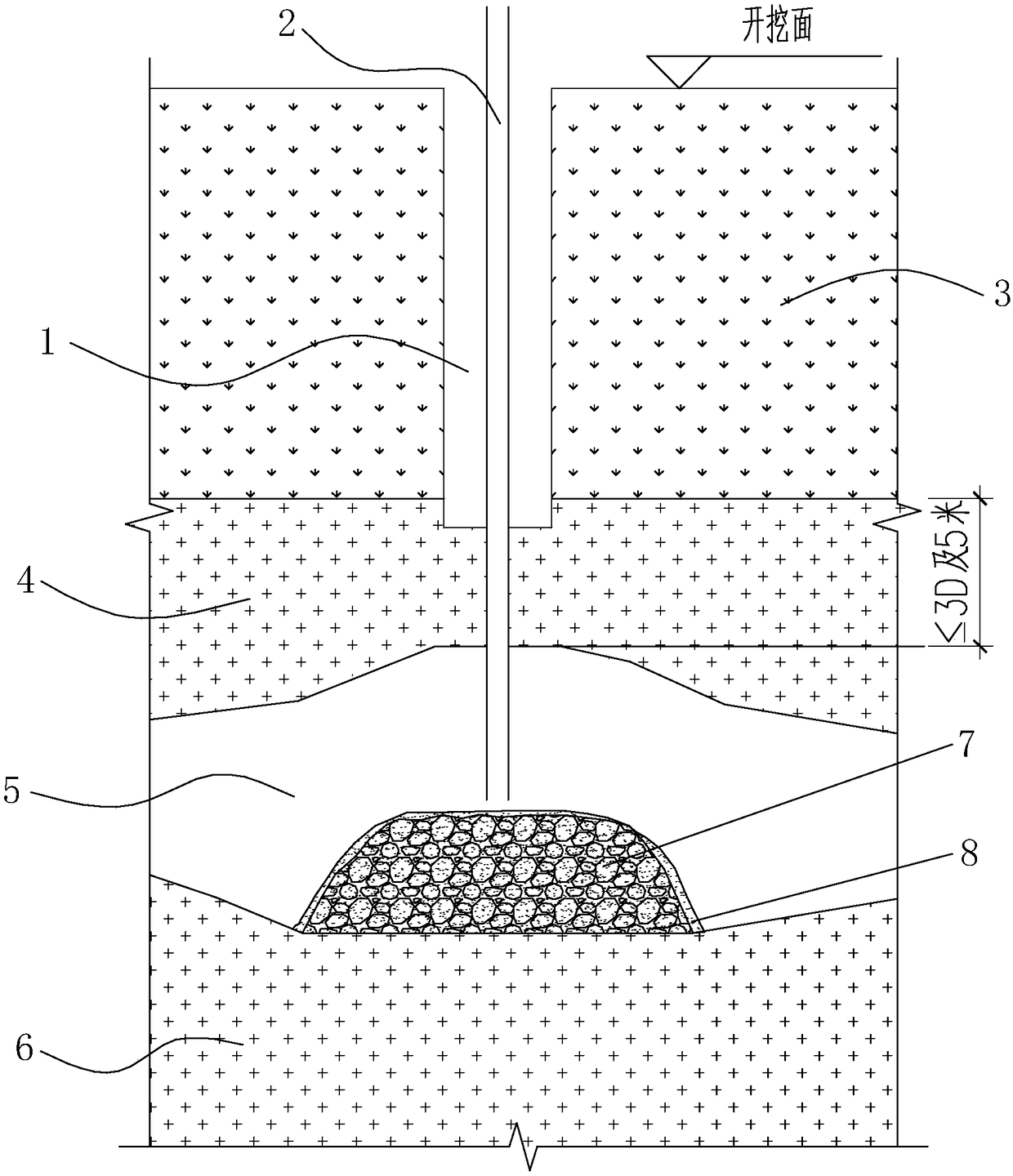

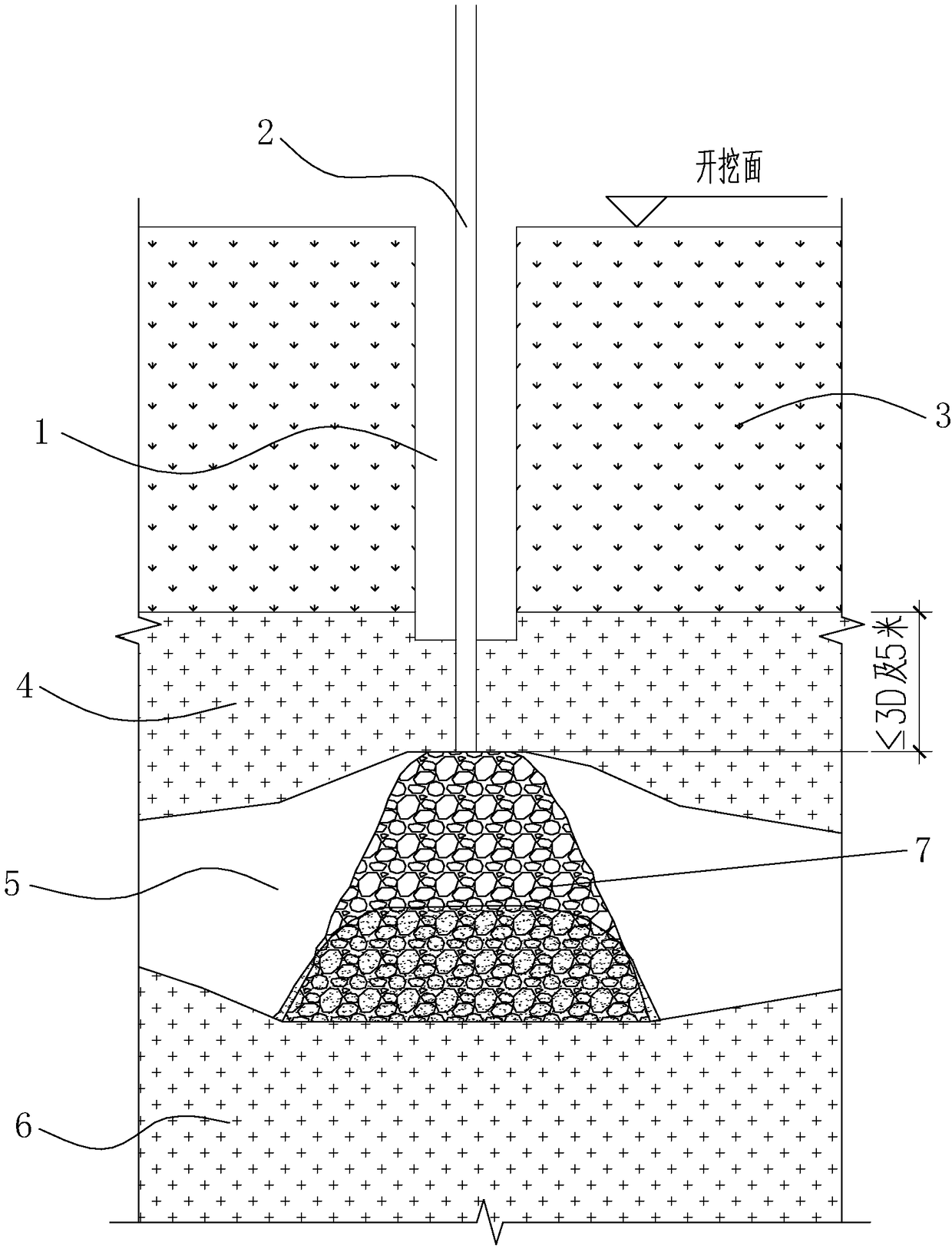

[0045] like Figure 1 to Figure 5 The construction method for strengthening and strengthening the karst caves of underground pile foundations shown is suitable for pile foundations where the thickness of the bearing layer is less than 3 times the diameter of the pile body and the thickness of the bearing layer is less than 5 meters, and there are caves with a height of ≥ 3 meters below the bearing layer Pile foundation construction includes the following steps:

[0046] Step (1), advanced drilling: According to the investigation data of the project, it is shown that there are karst caves 5 in the site, and the advanced drilling is carried out before the pile is formed, and the advanced drilling depth should be drilled to the karst caves 5 below the bottom of the proven pile;

[0047]Step (2), opening: adopt pile driver to open pile hole 1 to the design elevation at the bottom of the pile;

[0048] Step (3), deep drilling: use a pile driver to drill the micro-steel pipe 2 to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com