Construction method of long protective tube impact-cone concrete pile in ultra-thick silt area

A construction method and cast-in-situ pile technology, which is applied to sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of reducing the filling coefficient of piles, collapse holes, sinking hammers, and increased costs, so as to reduce the filling of piles coefficient, ensuring the quality of the pile, and accelerating the recovery speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

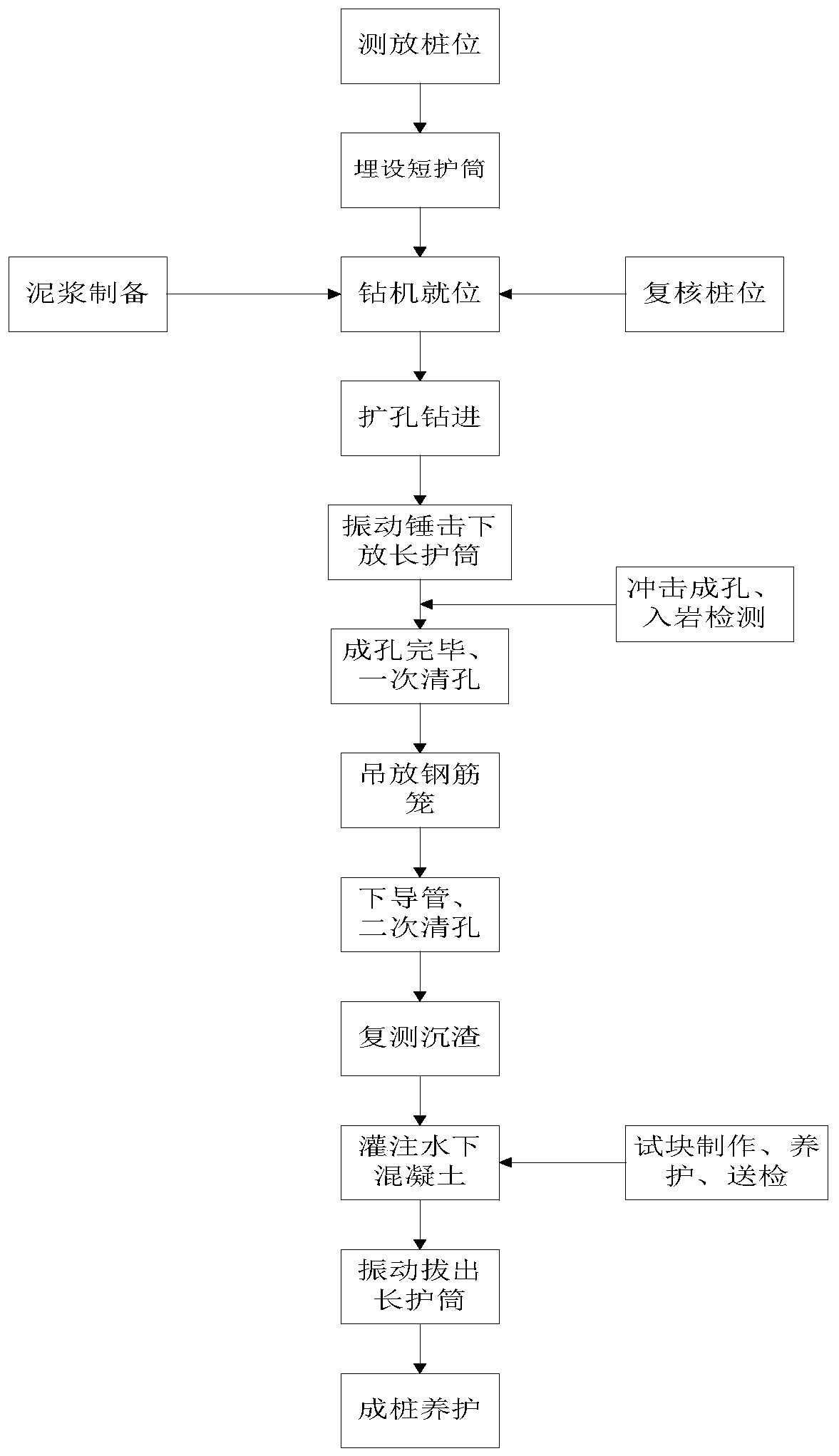

Method used

Image

Examples

Embodiment Construction

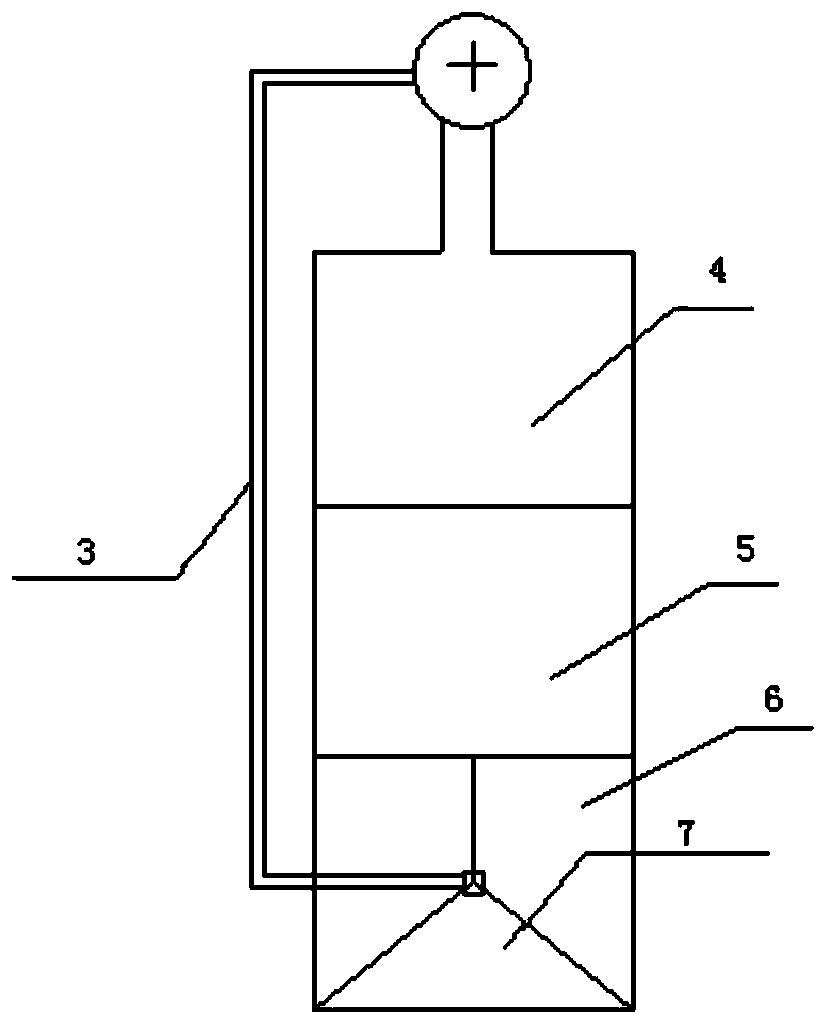

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

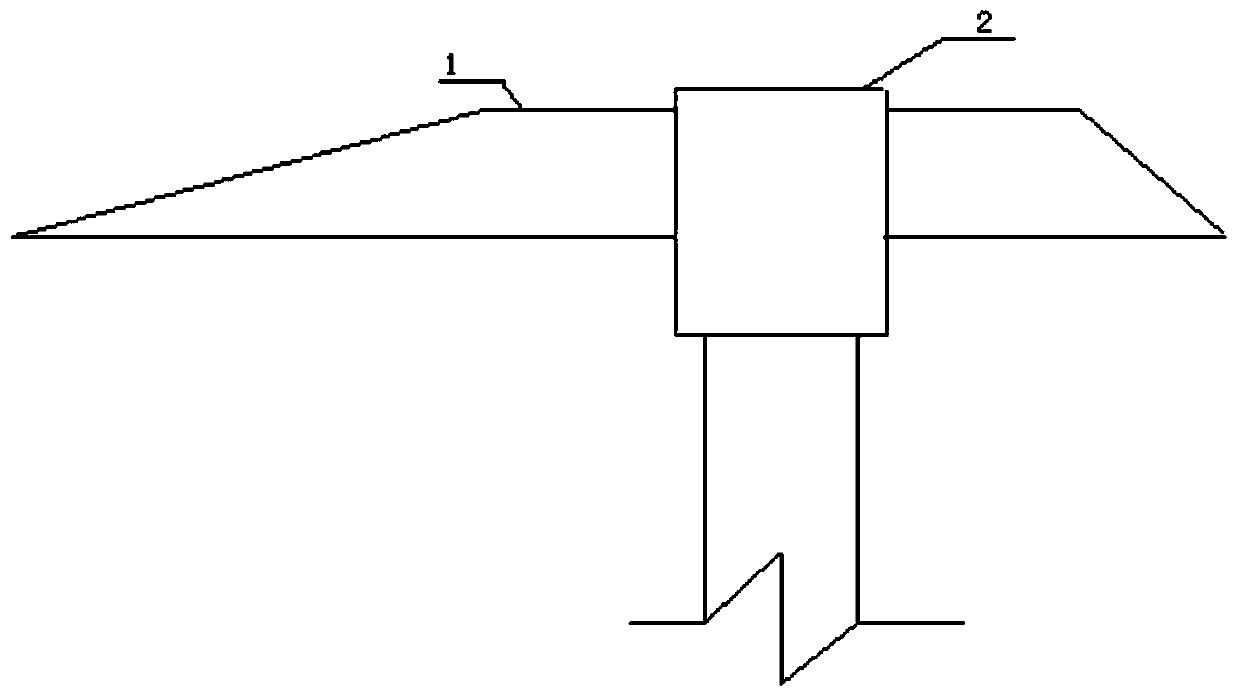

[0032] The method of the invention is used to carry out the construction of long casing perforated cast-in-place piles in an ultra-thick silt area under certain geological conditions of short-term reclamation and land reclamation.

[0033] Before the construction survey, carefully familiarize yourself with the drawings, understand the design intent and construction requirements, calculate and convert the coordinates of the pile positions, and carefully check the elevation, axis and coordinates of the drawings to ensure that the data is accurate.

[0034] High-precision GPS or total station positioning and steel ruler measurement are used for measurement, positioning and setting out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com