Double-protective barrel impact pile-forming method at silt rock soil layer

A technology of double casing and silt, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of difficult hole forming, shrinkage of pile body, block stone jamming and other problems, so as to improve the efficiency of pile forming and avoid The effect of reducing diameter and filling factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below by specific examples.

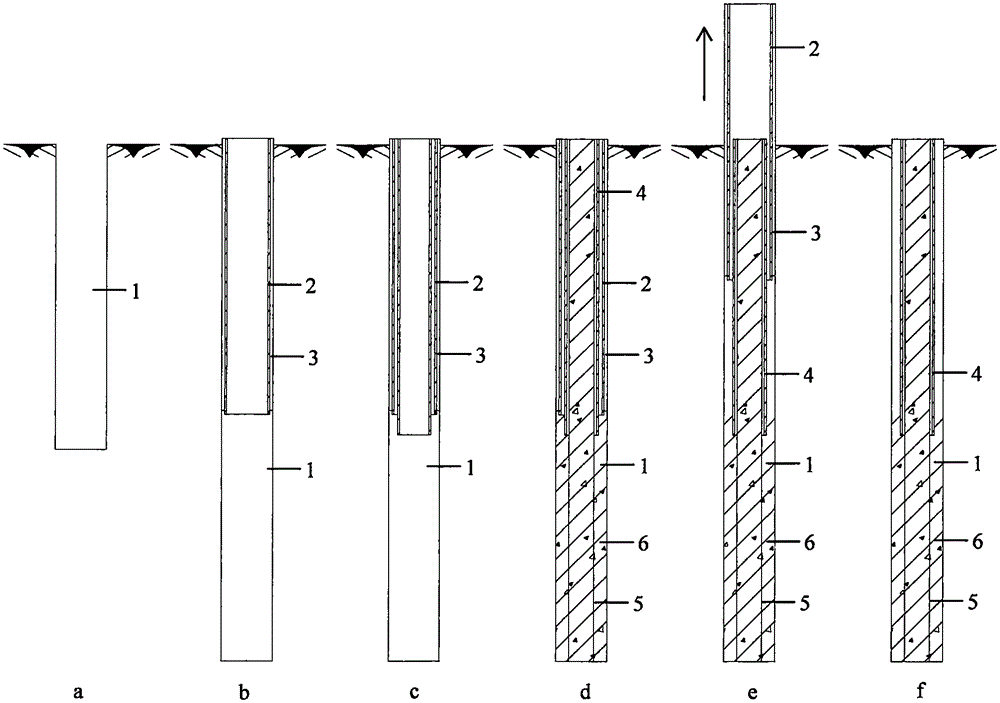

[0029] figure 1 It is a process diagram of an embodiment of a method of impacting piles with double casings between silt and stone-soil layers of the present invention. First, as figure 1 As shown in a, at the pile position in the foundation, the pile hole 1 is formed by impacting the construction machine tool, and the punching depth is the thickness of the rocky soil layer between the silt; then, as figure 1 As shown in middle b, the steel outer casing 2 is sunk into the pile hole, and several water injection pipes 3 can be welded on the outside of the steel outer casing, and the upper opening can be fixed reliably; then, as figure 1 As shown in c, continue the construction of the pile body punching until the design depth, after the first hole cleaning, hang the steel inner casing 4, and fix the upper mouth reliably; then, if figure 1 Shown in middle d, lower the pile body reinforcement cag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com