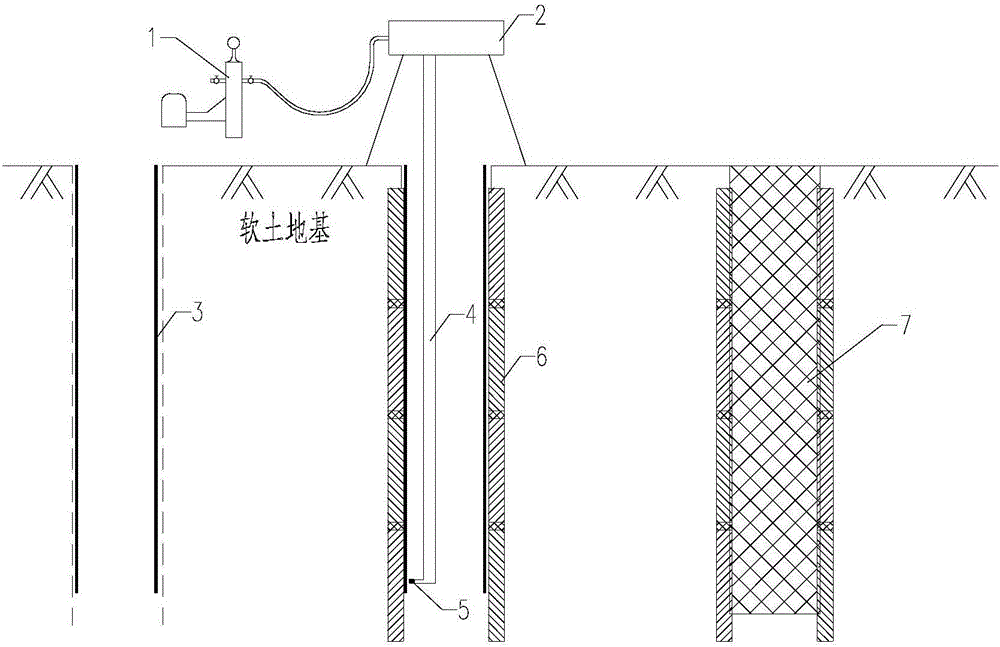

Equipment and method for improving bearing capacity of cast-in-place pile under soft soil foundation condition

A technology of soft soil foundation and cast-in-situ piles, which is applied in the field of foundation engineering, can solve the problems of difficulty in exerting the side friction of piles, reduce the bearing capacity of cast-in-situ piles, and low mechanical strength of soil, so as to improve load transfer performance and enhance soil quality. Strength, the effect of increasing the side friction of pile foundation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A high-grade highway is to be built in a coastal area, and the road section is formed by shallow sea dredging. The site is covered with a layer of silty clay with a thickness of 15m. The physical and mechanical indicators and main engineering parameters are shown in the following table:

[0049]

[0050] If the conventional soft foundation treatment method is used, it will not only consume a lot of engineering funds, but also have a long construction period. Therefore, it is decided to use the bridge scheme to span the weak foundation. The bridge foundation is designed as end-bearing friction bored piles, and the static load test of the test pile , the design test pile diameter is 800mm, the effective pile length is 33m, and the ultimate bearing capacity of a single pile is 5300kN. However, after the test pile was completed, the static load test found that the ultimate bearing capacity of the pile foundation only reached 3600kN, which could not meet the design require...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com