Construction method of concrete filling piles

A construction method and concrete technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as rising construction costs, loss of poured concrete, collapsed holes, etc., to achieve the effect of saving cost and ensuring the quality of forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The construction method of the concrete pouring pile as an embodiment of the present invention comprises the following steps:

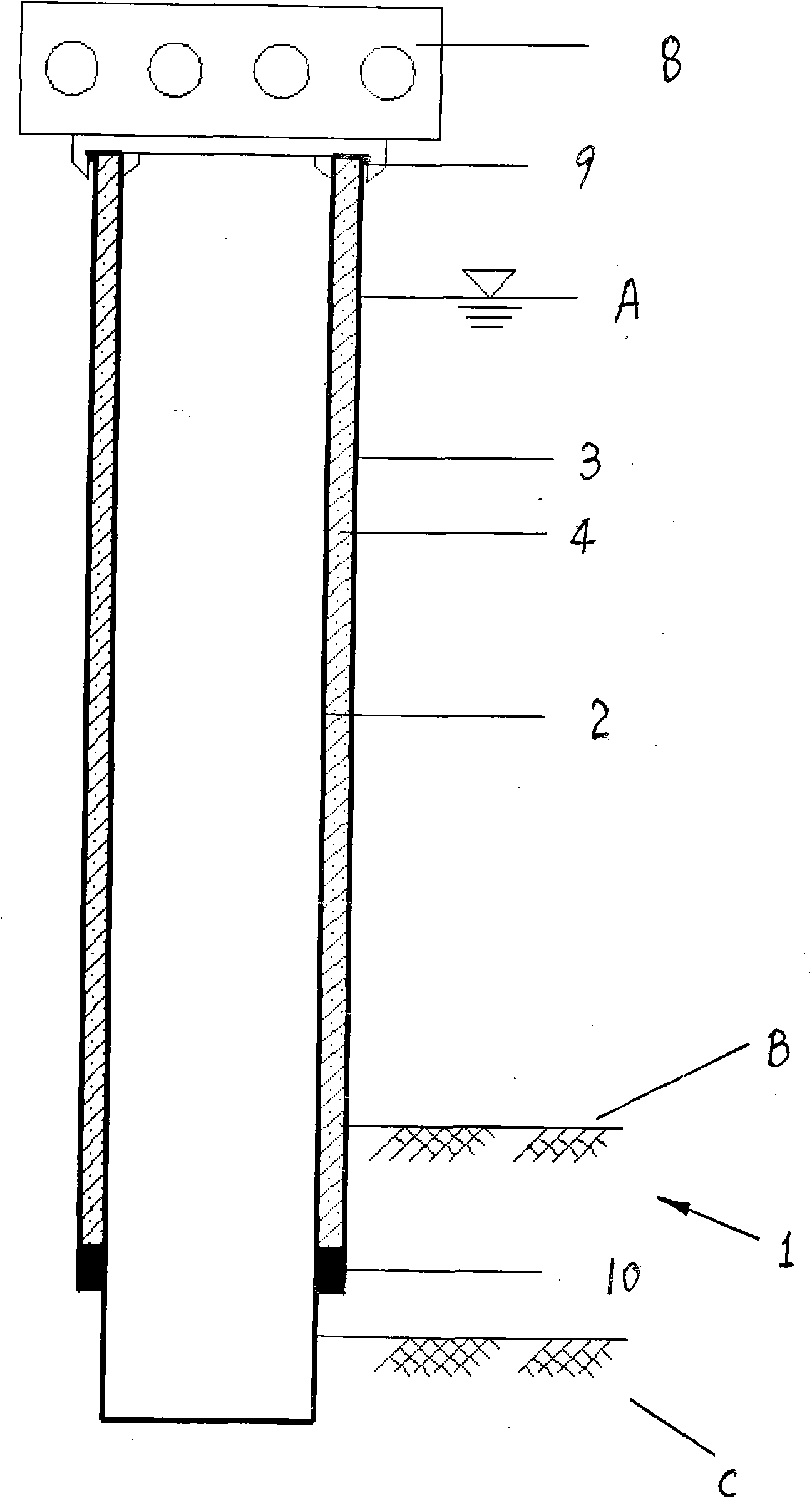

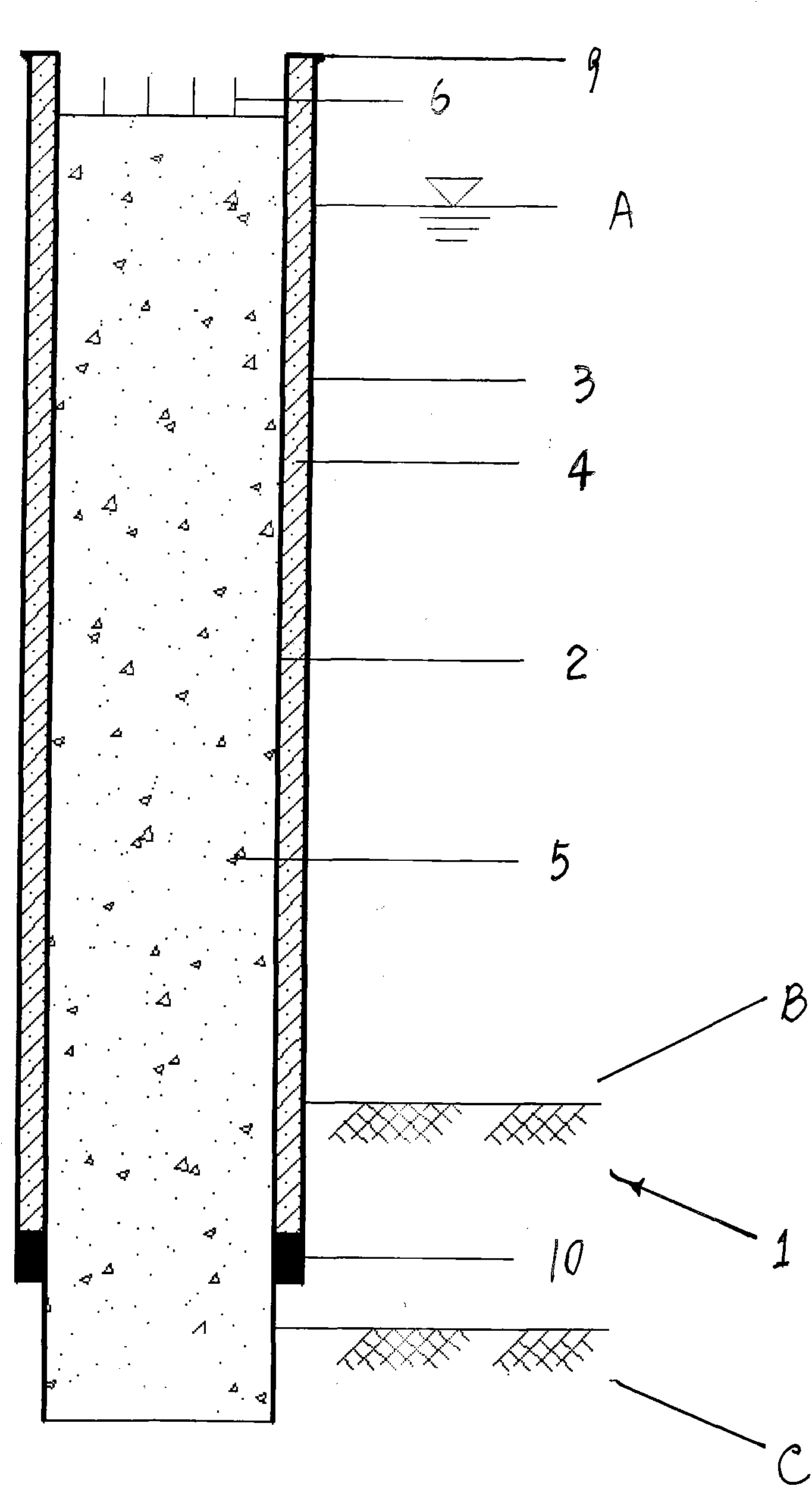

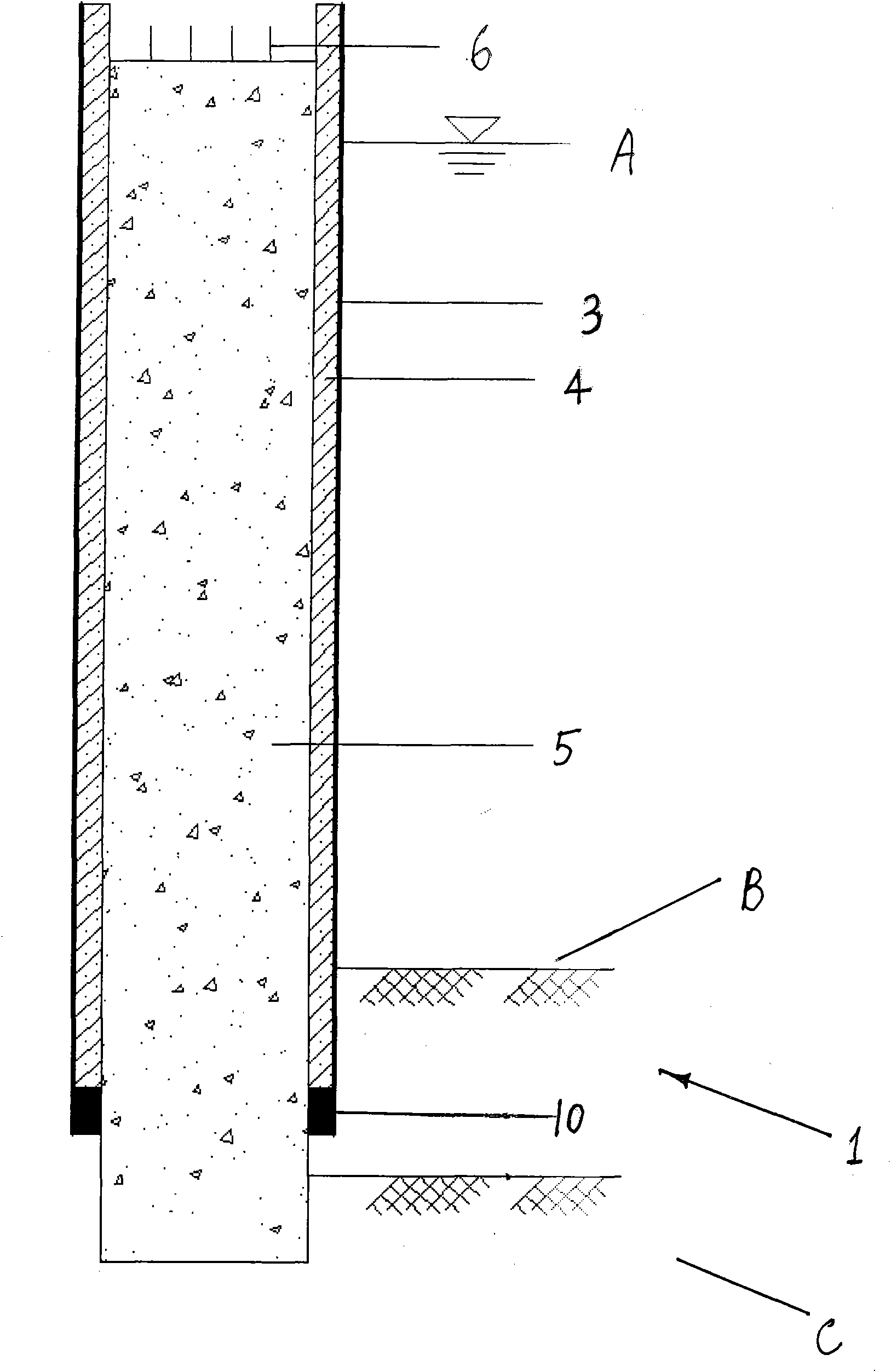

[0029] 1) if figure 1 As shown, two concentric inner and outer casings 2 and 3 nested in the foundation 1 are buried. Between the inner casing 2 and the outer casing 3, pressure injection is used as filling for forming a concrete pouring temporary form. The thick mud 4 of the material, the soil in the inner casing 2 is taken out to the ground to form a pile hole. At this time, the above-mentioned soil extraction can be carried out in various ways, such as auger drilling, drilling bucket soil extraction, etc. . Here, the embedding operation of the above-mentioned inner casing 2 and the outer casing 3 is carried out by using a high-frequency hydraulic vibratory hammer 8, and the above-mentioned inner and outer casings 2, 3 are vibrated and driven into the water surface A until the bottom of the pile is inserted into the foundation 1, reaching B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com