Double-casing-pipe full-circle-swinging erect column pile construction method

A column pile, full rotation technology, applied in sheet pile wall, infrastructure engineering, construction and other directions, can solve the problems of torsion of steel bar cage, drop of top elevation of steel column pile, shortening of length, etc., to reduce the torsion of steel bar, The effect of short pile forming time and strong cutting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The project overview of this example is: the total construction area of the first inspection office project of the main stadium of an Olympic sports center is 216,000 square meters, with one basement and six floors above the ground. The center is a large-scale sports building ancillary building, and the main stadium stand and ancillary rooms are reinforced concrete frame shear wall structures. Because the project is close to the river, the original soil base is fine sand layer, and the bearing capacity of the foundation is insufficient.

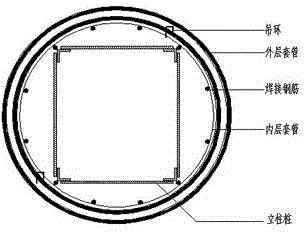

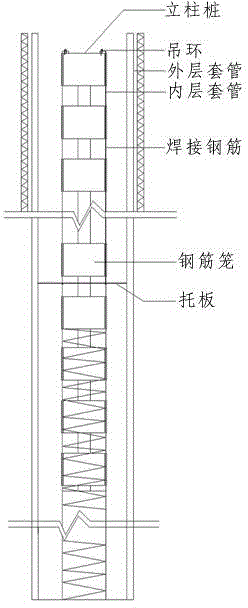

[0023] Adopt the method construction of the present invention, design and use pile diameter to be the column pile of 1000mm equally, the length of pile is 7m, what column pile adopted is 360 ° of double casing full rotary drilling rig construction. The specific steps are as follows: first, the positioning of the pile driver, using the full-rotation casing method, first press the outer casing (about 9m in length), and take soil; secon...

Embodiment 2

[0025] The project overview of this example is: a reconstruction project with a total construction area of 72512.7㎡ and a building height of 172.1m consists of a 46-storey tower building, 5 storey commercial buildings above ground, 3 storey underground garages and equipment rooms. The excavation depth of the foundation pit is 15.00m, and the excavation depth of partial pits is 18.70m. Due to the obstacles such as concrete left in the foundation of the reconstruction project, it is relatively hard.

[0026] Adopt the method construction of the present invention, the pile diameter of the steel column pile as vertical load-bearing member is 1000mm, and the pile length is 13.9m, and what steel column pile adopts is 360 ° double casing full rotary drilling rig construction. Among them, the outer diameter of the φ1000 casing is 1000mm (the same as the diameter of the column pile), and the inner diameter is 880mm; the outer diameter of the φ1200 casing is 1200mm, and the inner diam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pile diameter | aaaaa | aaaaa |

| Pile length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com