Vertical shaft bottom sealing method for mechanized construction in tunnel

A technology in construction shafts and tunnels, applied in tunnels, tunnel linings, shaft equipment, etc., can solve the problems of difficult bottom sealing, cracking of ballast concrete, and large underground resources, and achieve the effect of saving underground resources and reducing the quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

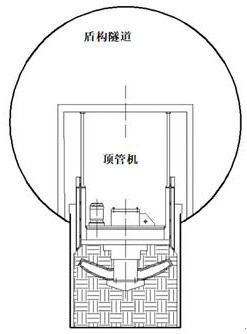

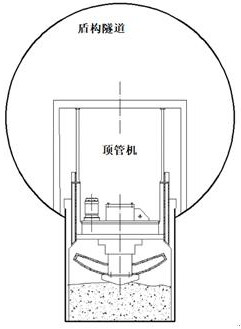

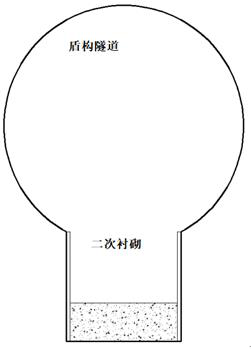

[0020] The structure of the bottom seal of the mechanized construction shaft in the tunnel includes shields, folding cutter heads, hydraulic cylinders and extended seals. The hydraulic oil cylinder is connected with the shield body and the folding cutter head through the support on the flange, and is fixed through the pin connection. The extended seal is installed on the top flange surface of the inner shield of the pipe jacking machine, and is connected with the shield by bolts. After the pipe jacking machine in the vertical shaft digs to a predetermined depth, concrete is poured in front of the cutter head through the concrete conduit preset by the central axis of the cutter head on the pipe jacking machine. The amount of poured concrete is matched to ensure that the groundwater does not destroy the mud film and pour into the mud water tank of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com