Deep-hole backward grouting and water-blocking construction method for igneous rock water-rich fault

A construction method and a backward-type technology, applied in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve problems such as difficulty in achieving effective results, and achieve the effect of ensuring rapid construction, good continuity and obvious economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

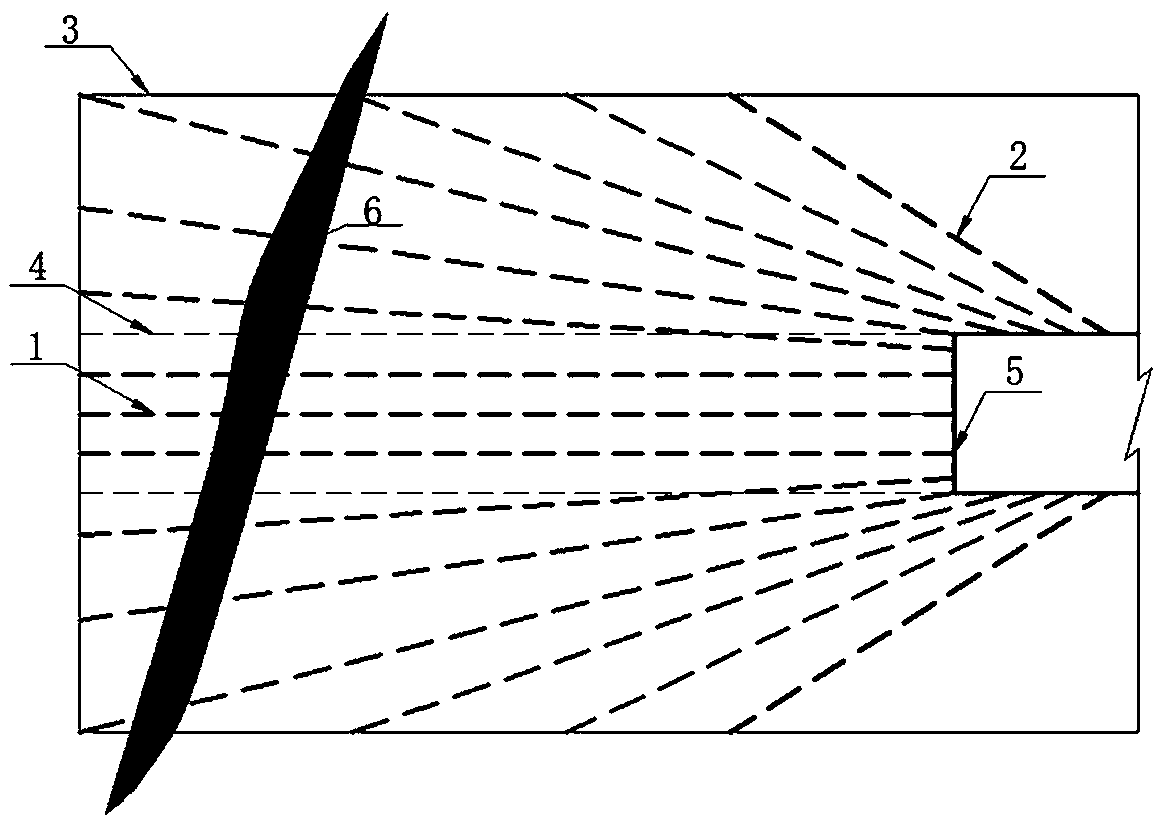

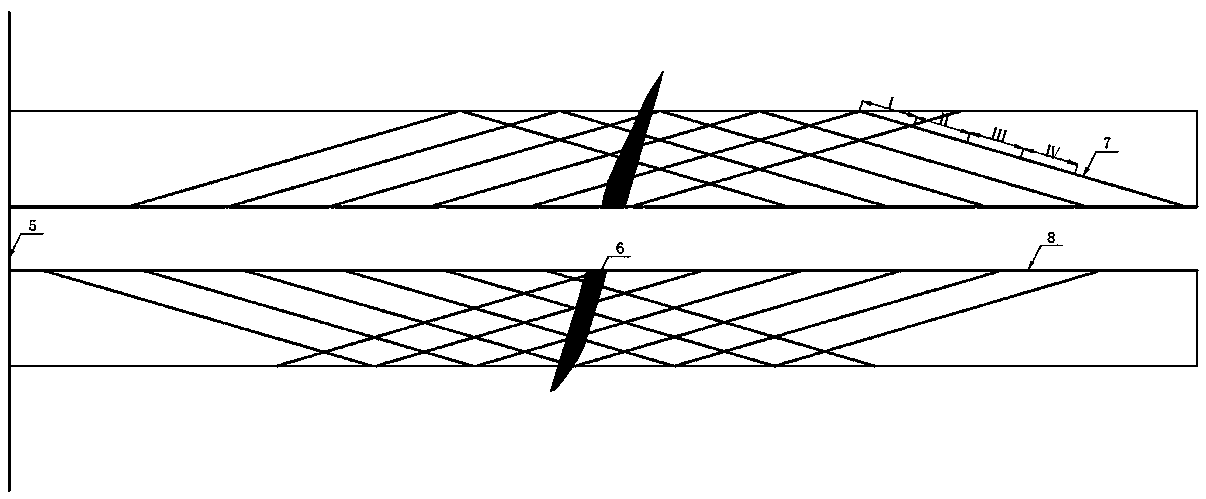

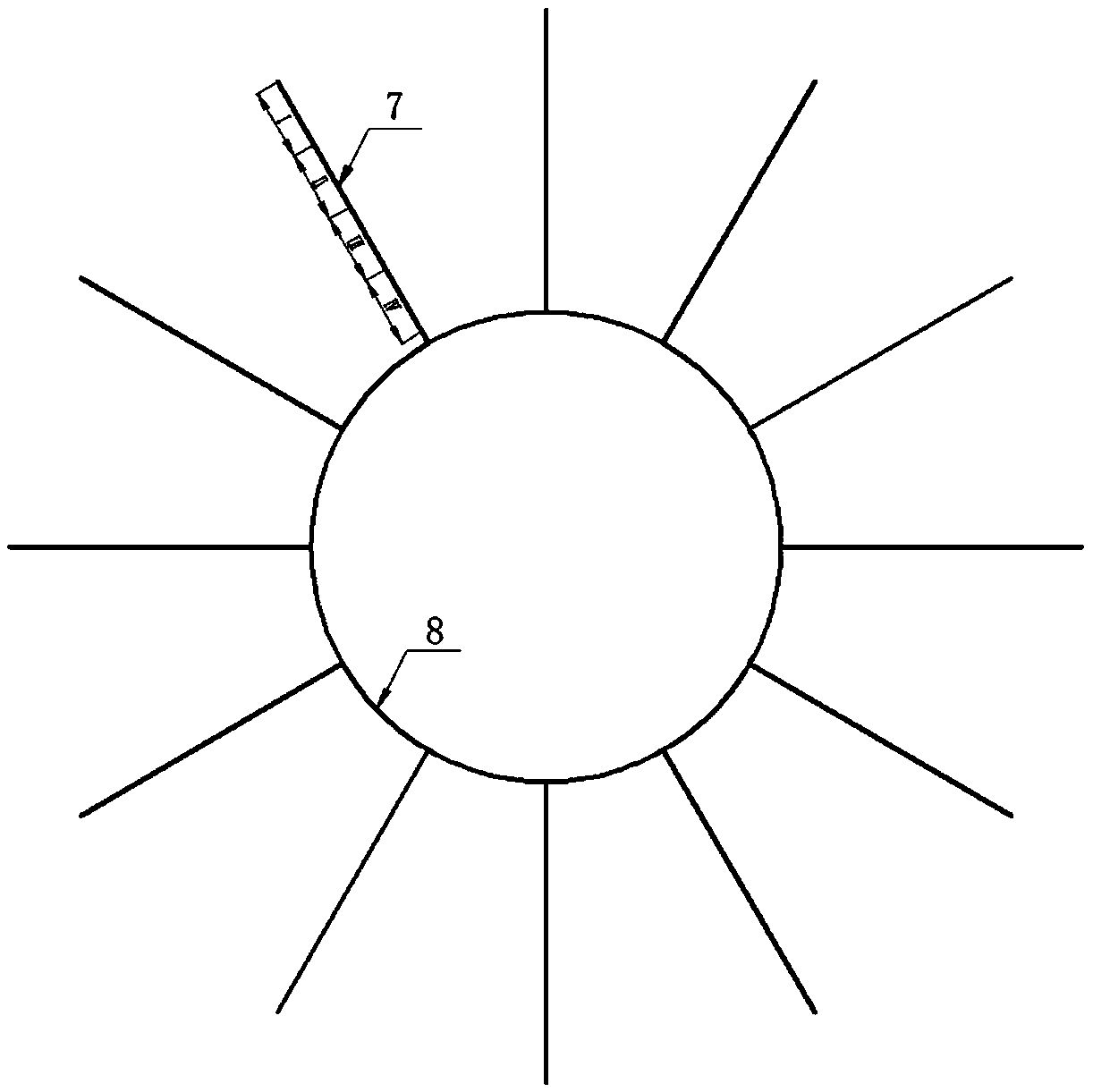

[0024] Combine below figure 1 , figure 2 , image 3 To further explain the present invention:

[0025] When tunneling through igneous rock (mainly granite) in a certain area of Qinling Mountains encounters difficulty in blocking water in the fracture zone of water-rich faults, a deep hole retreat grouting construction method for water-rich faults in igneous rock is provided. The specific steps are as follows:

[0026] 1) According to the geological data, when the tunnel excavated by smooth blasting is driven to about 50m in front of the fault fracture zone 6, the advanced drilling hole is used to detect the occurrence of the fault in front of the tunnel face 5 and the underground water inflow and water pressure. In this case, the advance drilling holes are arranged in a fan shape, the diameter of the drilling holes is 50mm, and the number of exploration holes is 5, which are distributed axisymmetrically. The angle between the external oblique eye and the middle eye is 3°-6°, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com