Integrated reinforced coal seam gas extraction system and extraction method

A coal seam gas and drainage technology, which is applied in the field of integrated enhanced coal seam gas drainage system, can solve the problems of small crack expansion range, small drainage radius, and inability to desorb gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

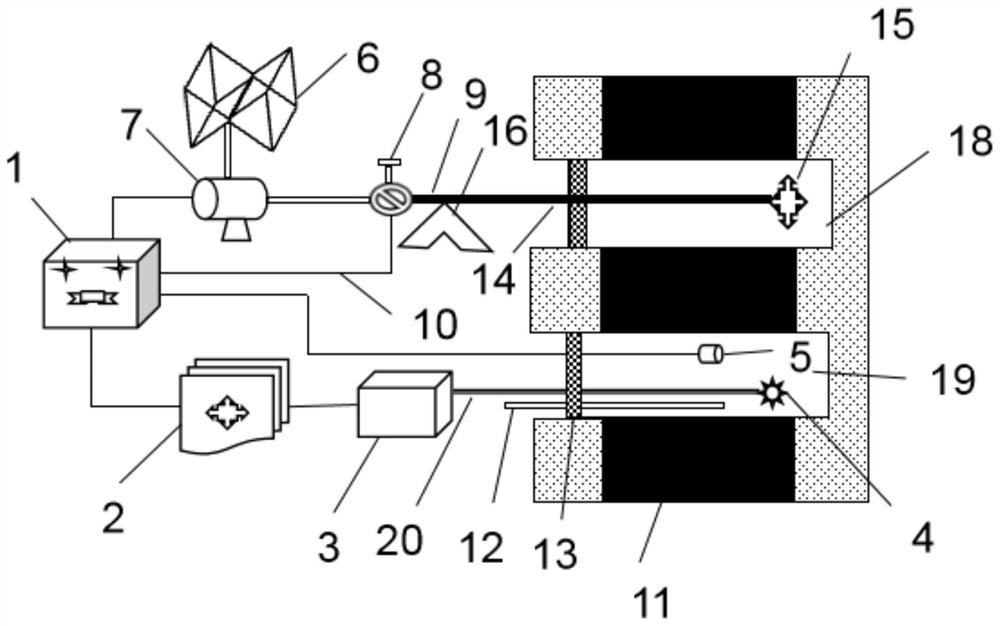

[0033] Example 1, please refer to the attached figure 1 , an integrated enhanced coal seam gas drainage system, including a pulse hydraulic system and a pulse microwave generation system, the pulse hydraulic system mainly includes a pulse control system 1, a water storage tank 6, and a high-pressure water pump 7, and the pulse microwave generation system mainly includes A pulse control system 1, a microwave source 2, and a waveguide 3. The pulse control system 1 is respectively connected to the high-pressure water pump 7 and the microwave source 2 through wires 10, so as to control the pulse hydraulic system and the pulse microwave generation system. The forward pulse output of the pulse control system 1 is the action time of hydraulic measures, and the reverse pulse output is the microwave action time. The waveguide converter of the microwave system has a resonant waveguide slot antenna array. The pulse hydraulic system is connected with the expansion drill pipe 14 through th...

Embodiment 2

[0044] Example 2 is used as a comparison scheme, alternately using hydraulic measures and microwaves to act on the coal body according to the pulse direction, and the existence of microwaves can reduce the output pressure of high-pressure water in hydraulic measures by about 10 MPa, so Example 2 is abandoned.

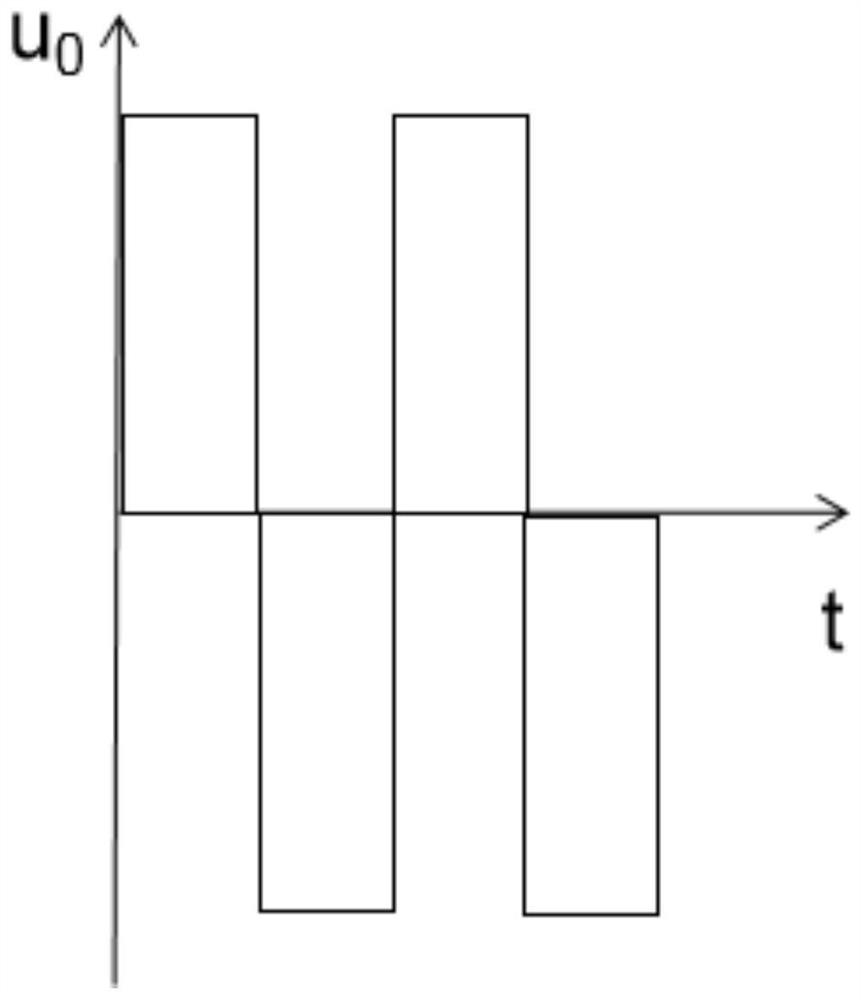

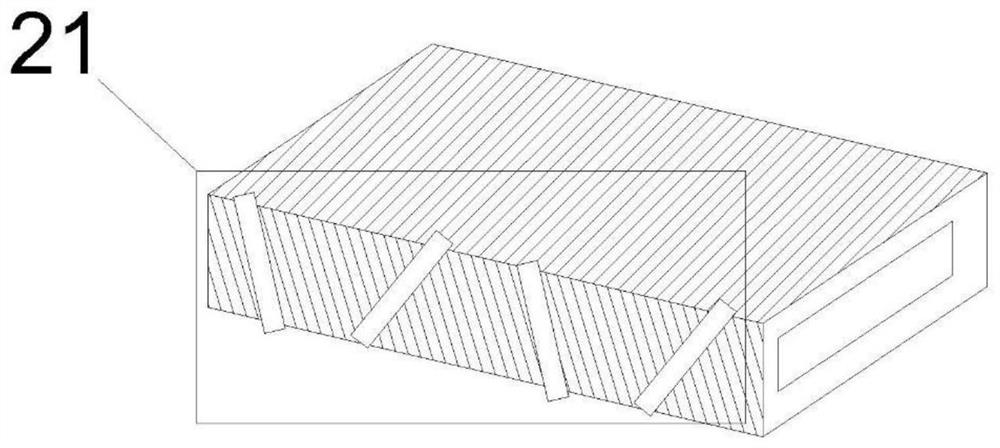

[0045] figure 2 Shown is the pulse waveform periodogram, image 3 The schematic diagram of the waveguide converter is shown. This method can expand the original pores and fissures, add new fissures, and form more pore and fissure network maps, which is beneficial to gas desorption, increases the gas permeability of the coal seam, and increases the gas extraction volume of the coal seam.

[0046] A pulse microwave-hydraulic slotting-fracturing integrated coal seam permeability enhancement method, through the combination of microwave and pulse hydraulic measures, can generate more micro-cracks in the coal body. The role of microwaves reduces the hardness of the coal sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com