Steel casing lead hole type pile planting construction technology

A construction technology and steel casing technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems affecting construction progress, slurry leakage, and lack of auxiliary steel pipe pile conditions, etc., to ensure the correct positioning rate and The effect of verticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

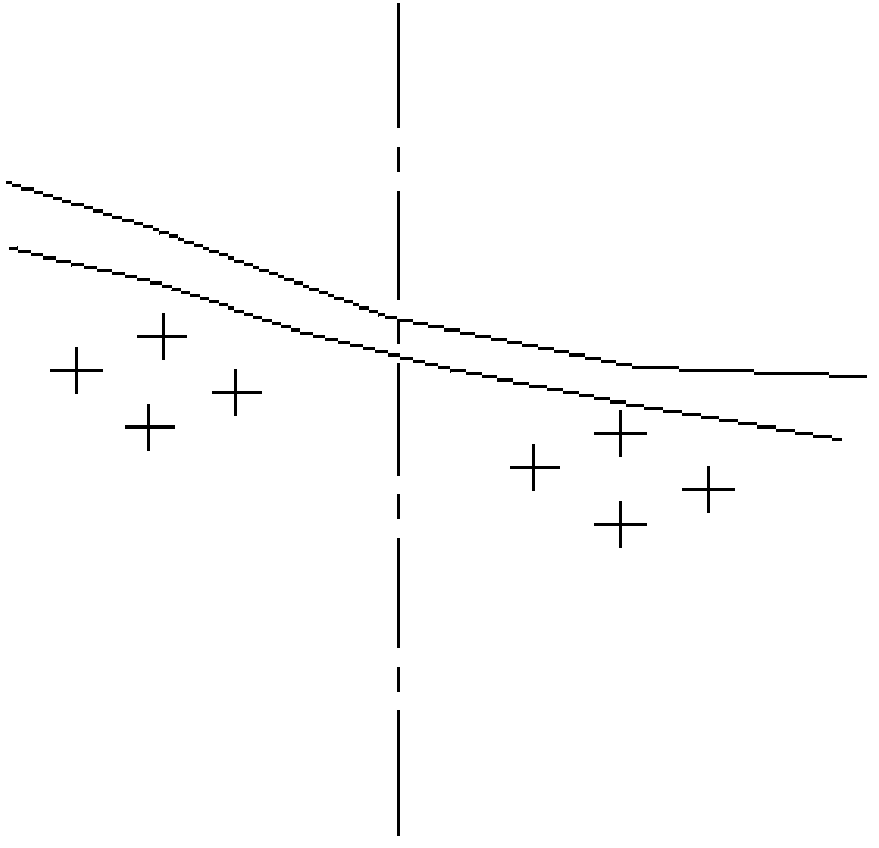

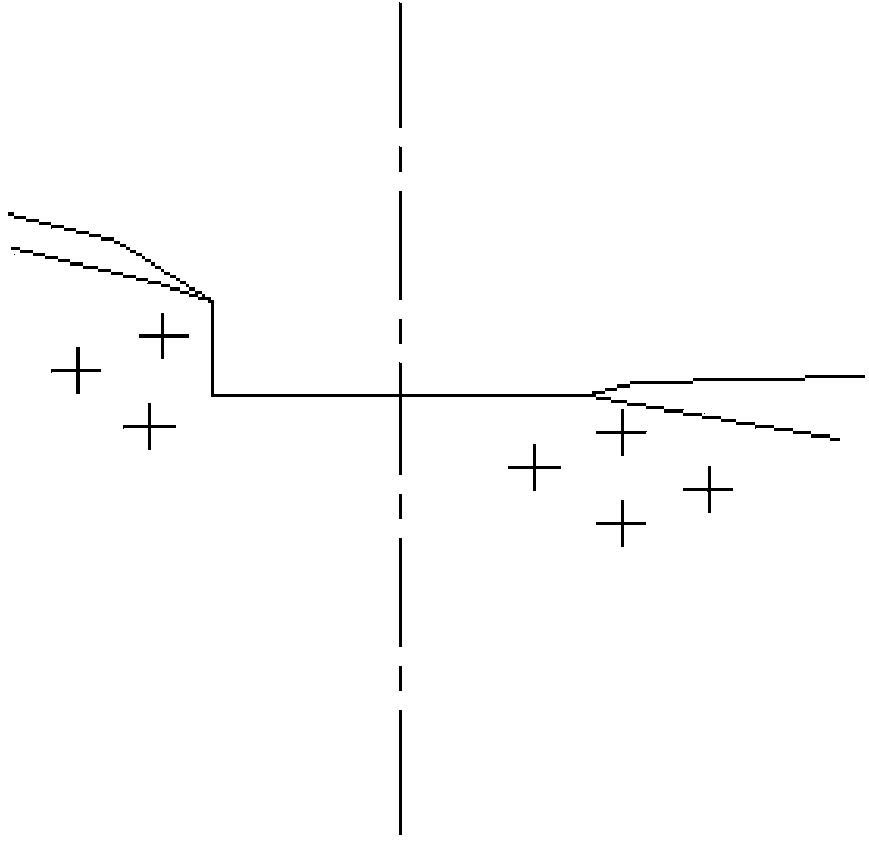

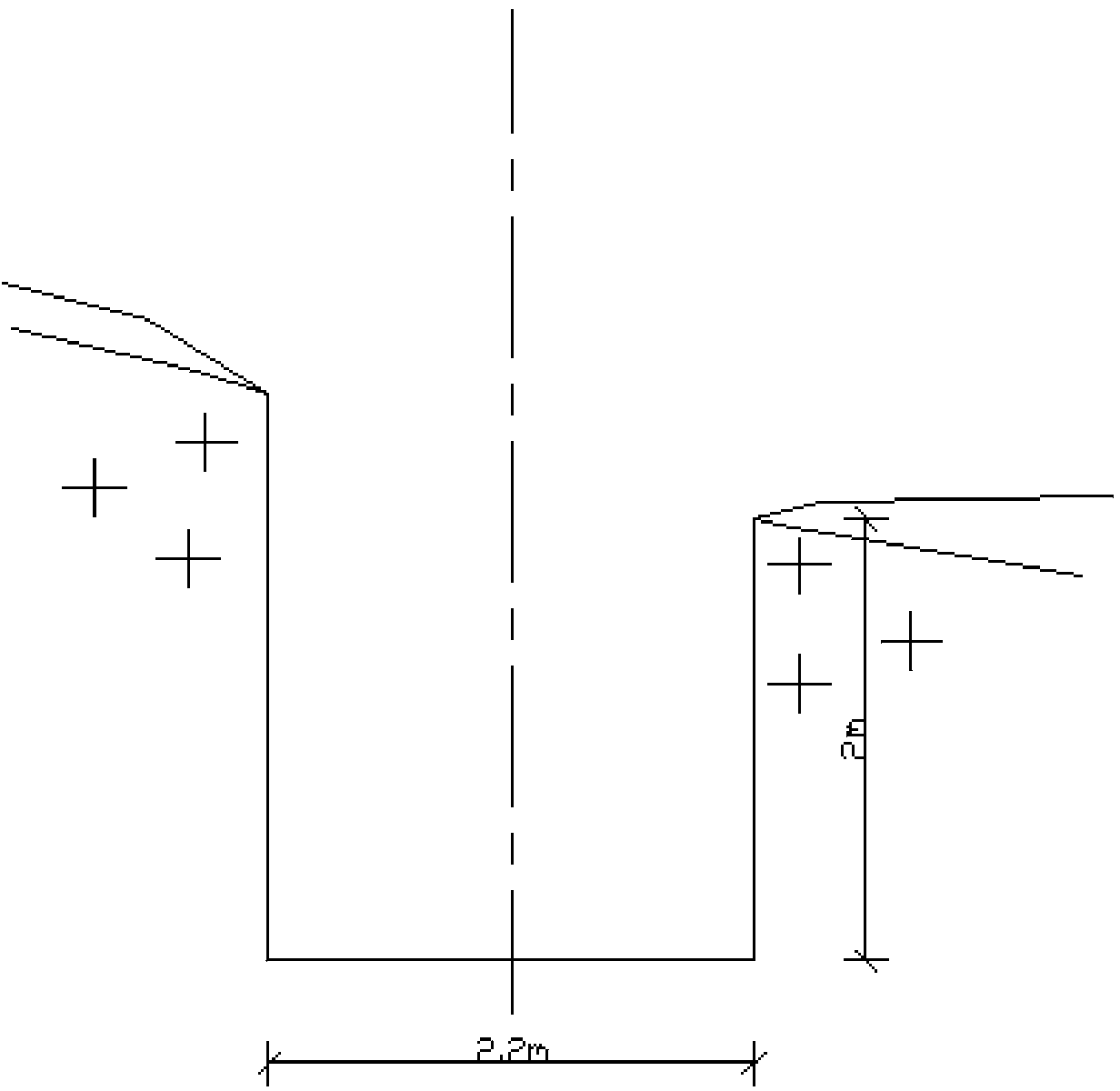

[0031] In this embodiment, the diameter of the steel casing is Φ1800mm. Considering the requirements of construction measurement control on the water and "implantation method" construction grouting, the diameter of the pilot hole is designed to be Φ2200mm; the pilot hole with a diameter of 2.2 meters is implanted into a steel casing with an outer diameter of 1.8 meters. From the process, the adjustment of the deviation of about 10cm in the pile position can be guaranteed.

[0032] The steel casing is self-heavy (single pile 20-30t), the anchoring depth is 2-2.5m, the anchoring concrete strength is high (underwater C30 concrete), the cross-section of the platform supported by the steel casing is small, and the horizontal force on the entire platfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com