Method for configuring double-tube metal-stream inoculation device on double-station tilting type casting machine

A flow-following inoculation device and double-pipe flow-following technology are applied in the field of a double-station tilting pouring machine equipped with a double-pipe flow-following inoculation device for casting. Reduce the working performance of flow inoculation device, vibration interference and other problems, to improve the quality of inoculation treatment and avoid the effect of working performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention can be explained in more detail through the following examples. The present invention is not limited to the following examples. The purpose of disclosing the present invention is to protect all changes and improvements within the scope of the present invention.

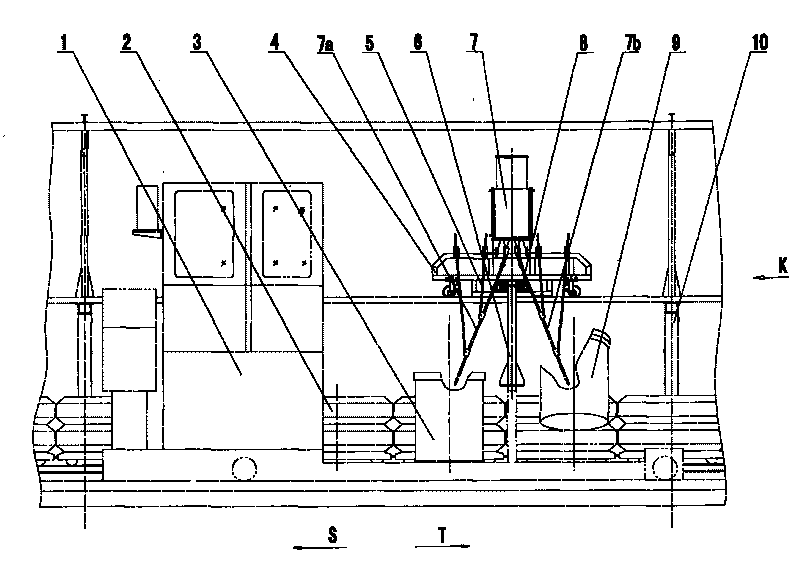

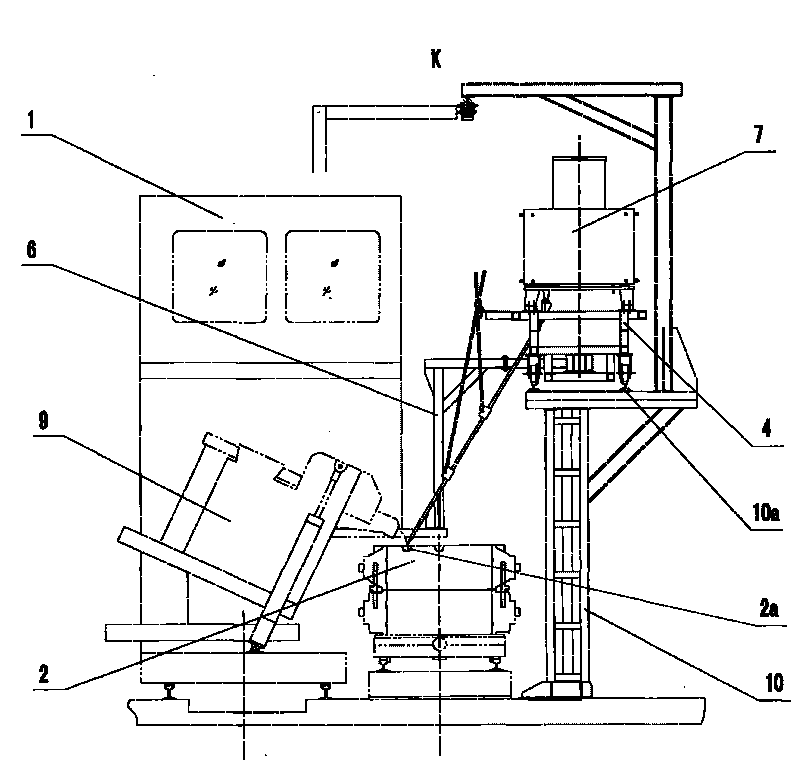

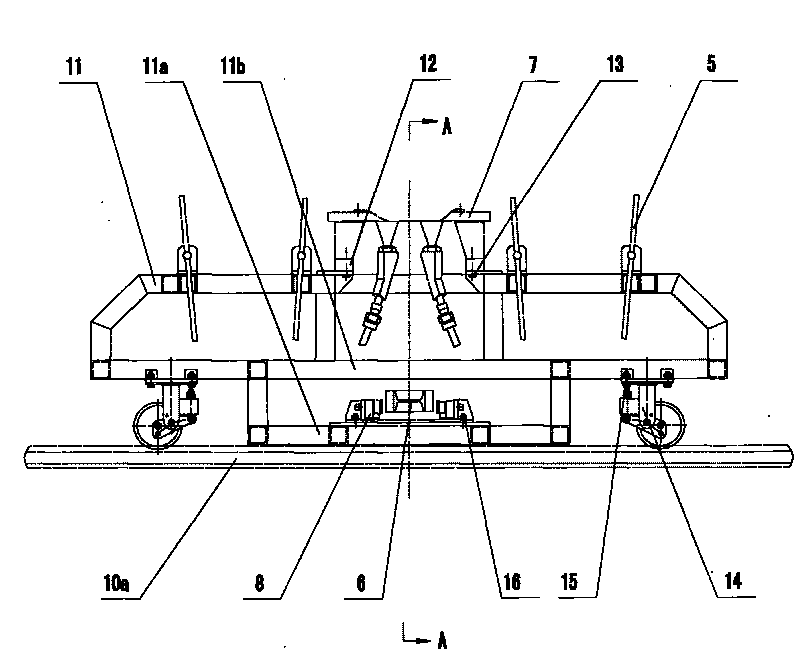

[0039] combine figure 1 , figure 2 It is known to implement the method of the present invention equipped with a double-tube flow-following inoculation device on a double-station tilting pouring machine, and the double-tube flow-flow inoculation device 7 is installed on the top of the shock-absorbing trolley 4, and Under the action of the blanking tube support assembly 5, the outlets of its blanking tube 7a and another blanking tube 7b correspond to the first pouring station and the second pouring station close to the double station tilting pouring machine 1 respectively. On the gate 2a of the sand box 2; wherein the shock-absorbing trolley 4 is located on two "work" shaped light rails 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com